Under the trend of popularizing disposable environmental protection products, disposable cup making machine has become the preferred equipment for many enterprises. With high degree of automation, easy operation, high speed and high qualified rate of finished products, the machine is suitable for manufacturing various paper cups such as coffee cups, tea cups, cold drink cups, etc. It is an indispensable and important production tool for the catering, packaging and retail industries.

Disposable Cup Making Machine Parameters

The above parameters are in line with the latest international market demand, especially suitable for small and medium-sized customers who are sensitive to cup machine price, the equipment is stable and reliable, fast return on investment.

| Model | YG-DP10 | YG-DP16 | YG-GS120 |

| Production Speed (pcs/min) | 80-110 | 70-90 | 100-120 |

| Voltage | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase |

| Paper Cup Specifications (oz) | 3oz-12oz | 3oz-16oz | 3oz-16oz |

| Machine Package Size (L*W*H, mm) | 2150x1100x1750 | 2150x1100x1950 | 2180x1050x1600 |

| Paper Stock / Material Requirements | 160-350g Single & Double PE Coated Paper | 160-350g Single PE Coated Paper | Single & Double Coated Paper |

| Power (KW) | 7.8KW | 5.5KW | 7KW |

| Weight (Kg) | 1700Kg | 1600Kg | 2100Kg |

| Appropriate customer groups | Start-ups or individuals | Small and medium-sized factories | Big factory |

| Paper Thickness Requirements (g/㎡) | 150-350g/㎡; ±20g/㎡ | ||

| Gas Supply Requirements | 0.6-0.8Mpa; 0.4m³/min | ||

| Cup Body Sticking Method | Ultrasonic Heating | ||

| Bottom Heating Method | Nest Bottom Heating (5 groups) | ||

| Molds Customization | Customizable According to Customer Requirements | ||

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | |||

Application Scenarios of Disposable Cup Making Machine

- Customized brand paper cups for restaurant chain enterprises;

- Disposable cup production in FMCG packaging industry;

- Export-oriented paper cup manufacturing factory;

- Entrepreneurial small production line projects, especially suitable for the equipment price (cup machine price) and efficiency requirements of balanced customers;

- Specific markets such as Brazil, Dubai, the growing demand for disposable cup manufacturing machine.

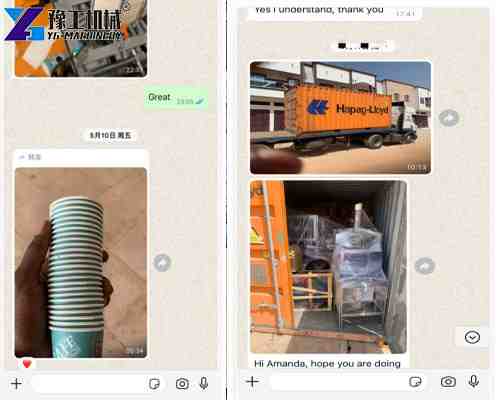

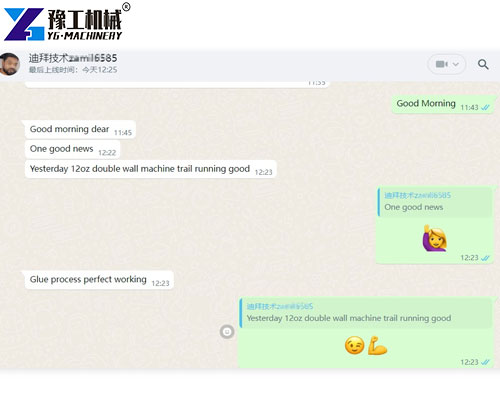

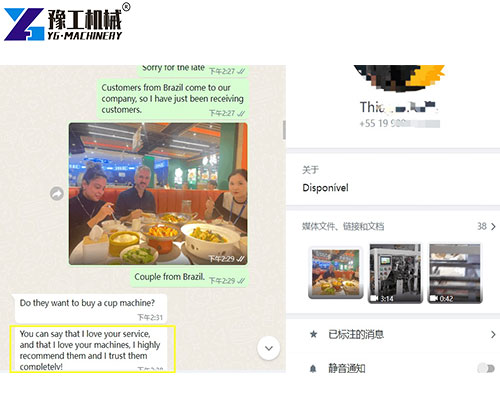

Overseas Customer Feedback

- Customer feedback from Sao Paulo, Brazil: “The disposable cup making machine runs stably, produces cups quickly, has a beautiful cup shape and good sealing, which meets the local market’s different needs for cold and hot beverage cups.”

- The customer in Dubai said, “The equipment is tightly assembled, the shipment from YG is detailed, the sample of paper cups provided meets the standard of local supermarkets, and the after-sales response is quick.”

This kind of feedback reflects the high reliability of the equipment in practical applications and YG’s expertise in the field of export packaging equipment.

Frequently Asked Questions FAQ

- What safety precautions should I pay attention to when using Disposable cup making machine?

Before running the machine, we should check whether there is any foreign matter in the transmission parts, don’t open the observation door freely when the machine is running, and change the lubricating oil regularly to prolong the service life. - What is the applicable paper range of the machine?

It supports 160-350g/m² single PE or double PE coated paper to meet different cup production requirements. - Is it possible to produce multiple cup sizes with one machine?

Each disposable cup making machine is equipped with one set of molds by default, which can produce paper cups within the range of 2-16oz, but only one size can be produced at a time. If you need different sizes, you need to purchase another mold. - How many cups can one ton of paper produce?

Take 190gsm paper as an example, 1 ton of paper can produce about 290,000 7oz paper cups. - Can we automate to reduce labor cost?

According to the demand, we can configure online linkage equipment for printing, die-cutting, cup loading, etc., to realize the whole line of automated production, and 2-3 people can manage the whole factory, which significantly reduces the labor cost. - Is it complicated to install the equipment?

The equipment has been commissioned in the factory, users only need to access the air compressor and power supply can be put into use. Randomly attached detailed video tutorials and operating instructions, easy to learn.

High Efficient Paper Cup Production in YG

As a leading manufacturer of paper cup equipment in China, YG is committed to providing high performance and cost-effective disposable cup making machine for customers all over the world. our products are exported to more than 30 countries, such as Brazil, Dubai, Italy, Kenya, etc., with a good reputation and stable service guarantee. Welcome to buy YG other high quality equipments: paper bowl forming machine, paper plate machine, coffee cup machine, automatic box gluing machine, paper tube production equipment.