In recent months, YG Machinery successfully delivered a complete production line including a steel bar upsetting machine, rebar thread rolling machine, and rebar splice coupler systems to a major contractor in Dubai. This equipment was deployed for the construction of a 50-story commercial building in the heart of the city. The feedback from the client has been overwhelmingly positive, particularly regarding the efficiency and durability of the machines under extreme weather conditions.

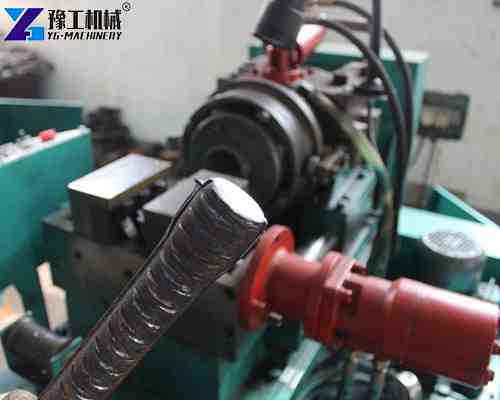

Rebar Thread Rolling Machine Parameter

| Model | HDCJ-32 | HDCJ-40 | GDCJ-40 |

| Processing Reinforcement Range | 12~32mm | 12~40mm | 12~40mm |

| Motor Power | 4Kw | 7.5Kw | 4Kw |

| Max.Flow | 5.42L/min | 4.0L/min | 6.4L/min |

| Pressure | 2036KN | 3000KN | 2036KN |

| Max Working Pressure | 80MPa | 31.5MPa | 80MPa |

| Dimension | 1020*500*965mm | 1300*830*1350mm | 1300*650*965mm |

| Weight | 560Kg | 900Kg | 600Kg |

Project Background

The client, a top-tier construction company in the UAE, was tasked with constructing a high-rise building requiring thousands of high-strength steel bar connections. Due to the region’s high temperatures and seismic safety requirements, they needed a solution that was faster and more reliable than traditional welding methods.

Coupler in reinforcement in the Middle East Construction Market

In areas like Dubai and Saudi Arabia, steel bar connections must withstand intense heat, sand, and moisture, especially in coastal or offshore projects. Traditional welding is not only time-consuming but also fails to deliver consistent results under such conditions. The company needed a high-performance steel bar upsetting machine and matching couplers to ensure that all reinforcement bars met local standards such as BS 4449 and ASTM A615.

YG’s Tailored Solution: Full Rebar Splicing System

To meet the contractor’s needs, we provided a complete rebar connection line, including:

- A high-precision rebar thread rolling machine for 16–40mm bars.

- A cold-forging steel bar upsetting machine to create stronger thread ends.

- Hot-dip galvanized couplers to ensure corrosion resistance.

- An intelligent PLC control system for consistent quality and easy operation.

This setup significantly boosted construction speed and provided a long-term, maintenance-friendly solution. The machines were designed to be heat- and dust-resistant—ideal for the harsh climate of the Middle East.

Key Advantages of Steel Bar Upsetting Machine

The adoption of this steel bar splicing solution delivered immediate benefits:

- 30% faster performance compared to manual welding.

- No sparks during operation, ensuring safety in high-temperature environments.

- Earthquake-resistant connections, tested in accordance with ISO 15835.

- Durable and corrosion-proof components suitable for marine or coastal projects.

With these advantages, the steel bar upsetting machine has become increasingly popular among contractors across the region.

Results and Client Feedback about Steel Bar Upsetting Machine

Within just three months of installation, over 5,000 rebar splices were completed with zero defects reported during third-party testing. The client also achieved a 20% cost reduction compared to using imported European machines.

The client praised the rebar splice coupler’s quality and expressed satisfaction with the system’s ability to meet tight construction timelines while maintaining international standards.

Rebar Coupler Manufacturer- YG Machinery

As a trusted rebar coupler manufacturer, YG Machinery provides not only reliable machines but also comprehensive after-sales service and technical support. Whether you are seeking punch and shear, rebar cutting bending machine, or threaded rebar coupler, YG offers proven, cost-effective technology that meets global standards. Get in touch with YG Machinery today.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.