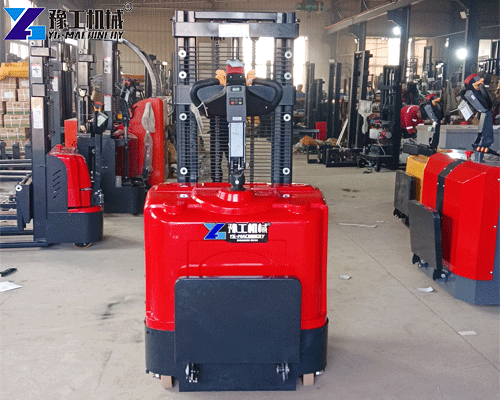

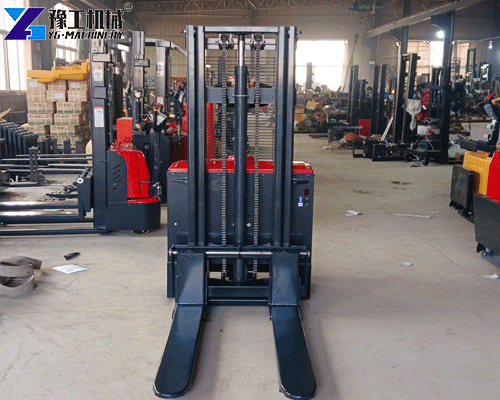

An electric stacker lift is a fully powered warehouse lifting machine designed to stack, lift, and transport palletized goods over short distances using electric drive and electric lifting systems. Compared with manual or semi-electric stackers, an electric stacker lift reduces labor intensity, improves stacking accuracy, and supports higher material handling efficiency in modern logistics environments.

What Is an Electric Stacker Lift?

An electric stacker lift uses an electric motor for both travel movement and fork lifting, powered by a rechargeable battery system. It is commonly used in warehouses, distribution centers, factories, and retail backrooms where palletized loads need to be moved and stacked safely.

Depending on configuration, electric stackers include:

- fully powered stackers (electric drive + electric lift)

- straddle stacker lift models for wider pallets or uneven floors

- electric pallet stacker for sale models optimized for cost-sensitive operations

Key Advantages of Electric Stacker Lifts

Electric stacker lifts offer measurable operational advantages compared with manual or diesel alternatives:

- Lower operating cost: Electric power reduces fuel expenses and daily operating costs

- Improved safety: Stable lifting, precise control, and reduced operator fatigue

- High maneuverability: Compact design for narrow aisles and indoor use

- Low noise and zero emissions: Suitable for enclosed warehouse environments

- Consistent lifting performance: Electric hydraulic systems provide smooth vertical motion

Fully powered stackers are especially effective for operations with frequent stacking cycles.

Applications of Straddle Stacker Lift

Electric stacker lifts are widely used across multiple industries:

- Warehouses and logistics centers

- Manufacturing workshops and assembly lines

- Cold storage and food distribution facilities

- Retail stockrooms and supermarkets

- Light industrial material handling

A straddle stacker lift is preferred when handling wider pallets, ground-level obstacles, or non-standard pallet dimensions.

Working Principle of an Electric Stacker Lift

An electric stacker lift operates through three core systems:

- Electric drive motor controls forward and reverse movement

- Electric hydraulic lifting system raises and lowers the forks

- Battery system supplies power to both travel and lifting functions

The operator controls speed, lifting height, and direction via handle or control panel, ensuring stable and precise pallet handling.

Types of Electric Stacker Lifts

Common configurations include:

- Fully powered stackers: Best for high-frequency, high-efficiency operations

- Straddle stacker lift: Enhanced stability and pallet compatibility

- Walk-behind electric stacker: Compact and cost-effective

- Adjustable fork electric pallet stacker: Suitable for multiple pallet sizes

Each type is designed for specific load capacities, aisle widths, and usage intensity.

What Affects Electric Stacker Lift Price?

The price of an electric stacker lift is influenced by several technical and configuration factors:

- Load capacity (e.g., 1t, 1.5t, 2t)

- Lifting height and mast type

- Battery type (lead-acid vs lithium battery)

- Drive system (standard or heavy-duty motor)

- Fork width and straddle configuration

- Safety and control features

A fully powered stacker generally costs more than a semi-electric model due to higher automation and productivity.

How to Choose the Right Electric Stacker Lift?

Selecting the correct model depends on operational requirements rather than price alone:

- Match load weight to rated capacity with safety margin

- Choose lifting height based on rack system

- Select straddle stacker lift if pallets vary in width

- Consider lithium battery models for high-usage shifts

- Evaluate aisle width and turning radius constraints

For long-term efficiency, fully powered stackers are recommended for medium to high workload environments.

Maintenance and Operating Considerations

Electric stacker lifts require relatively low maintenance compared with combustion equipment:

- Regular battery charging and inspection

- Periodic hydraulic oil checks

- Inspection of forks, chains, and wheels

- Software and controller diagnostics (if applicable)

Proper maintenance ensures stable lifting performance and longer service life.

FAQ: Electric Stacker Lift

What is the typical price range of an electric stacker lift?

Prices vary by configuration, capacity, and battery type. Entry-level models cost less, while fully powered stackers with lithium batteries are higher priced.

What is the difference between fully powered stackers and semi-electric models?

Fully powered stackers use electric motors for both movement and lifting, while semi-electric models require manual pushing.

What load capacity is most common?

1–2 tons is standard for most warehouse operations.

Is a straddle stacker lift necessary for all pallets?

No. It is mainly required for wider or non-standard pallets.

How long does battery charging take?

Lead-acid batteries require several hours; lithium batteries support faster charging and opportunity charging.

About YG Machinery

YG Machinery supplies electric stacker lift solutions for warehouse and industrial material handling applications. The company provides:

- Multiple configurations of electric pallet stacker for sale

- Custom load capacity and lifting height options

- Factory-direct manufacturing and quality control

- Technical support and after-sales service

YG focuses on functional performance, safety compliance, and long-term operational reliability.