A solar screw pile driver is a hydraulic piling machine designed to install helical piles or ground screws for solar photovoltaic mounting systems. Instead of impact driving or concrete foundations, this machine installs piles by controlled rotary torque, offering fast installation, high accuracy, and minimal soil disturbance—making it ideal for modern ground-mounted solar projects.

What Is a Solar Screw Pile Driver?

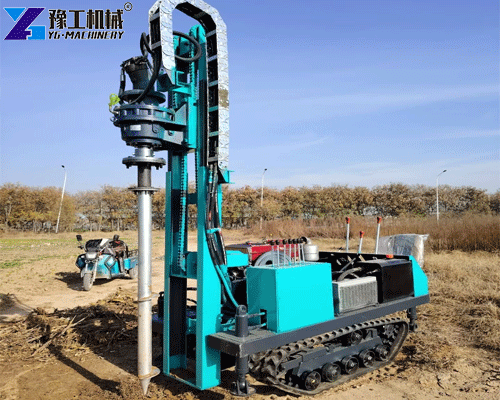

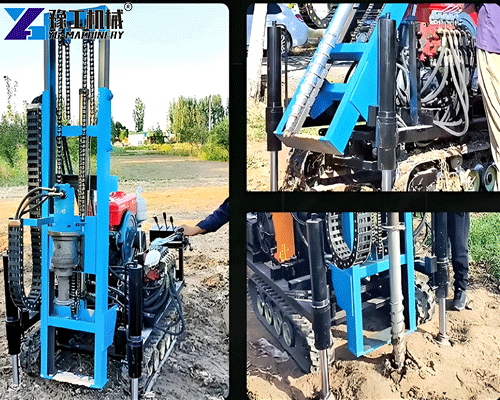

A solar screw pile driver is a crawler-mounted or skid-mounted hydraulic machine used to screw helical piles directly into the ground. These piles serve as the foundation for solar mounting structures.

Unlike traditional pile driving equipment, screw pile installation does not rely on hammering or vibration. The pile is rotated into the soil using a high-torque hydraulic rotary head, ensuring stable load-bearing capacity while protecting surrounding soil layers.

This method is widely used in utility-scale solar farms, agricultural PV projects, and distributed solar installations.

Solar Screw Pile Driver Parameters

| Model | YG-32S Solar Screw Pile Driver |

| Rig Weight | 1.2 tons |

| Engine Power | 32 HP |

| Rotary Head Torque | 3500 N·m |

| Borehole Diameter | 50–300 mm |

| Pile Depth | 1–3 m (customizable) |

| Walking Mode | Crawler gearbox |

| Climbing Ability | 35° |

| Hydraulic Legs | 4 |

| Applicable Soil | Medium soil, clay, weathered rock |

Specifications can be customized based on project requirements.

How Does a Solar Screw Pile Driver Work?

The working principle of a solar screw pile driver is based on torque-controlled rotary drilling rather than impact force.

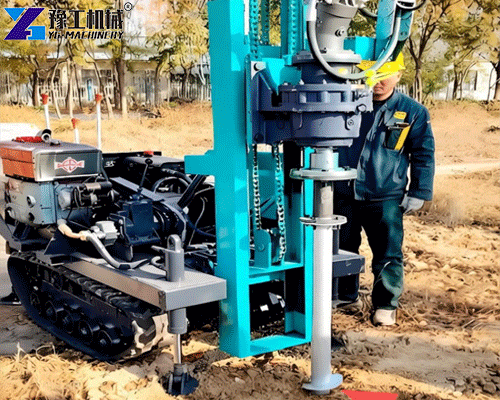

- The machine positions the helical pile vertically using the mast and guide system

- A hydraulic rotary head applies continuous torque

- The screw pile penetrates the soil layer by layer

- Installation depth and torque are monitored to ensure foundation stability

Because no concrete curing is required, the solar mounting structure can be installed immediately after piling, significantly reducing construction time.

Key Features of YG Helical Pile Driver for Solar

YG solar screw pile drivers are engineered specifically for photovoltaic foundation work, focusing on efficiency, adaptability, and reliability.

- High-torque hydraulic rotary head for stable screw pile installation

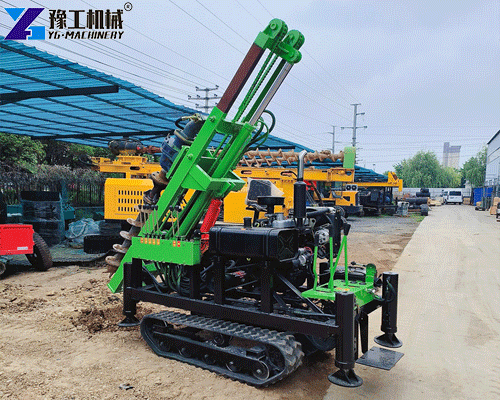

- Suitable for helical piles, ground screws, and spiral anchors

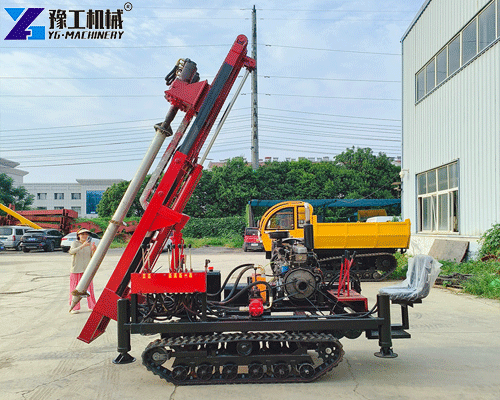

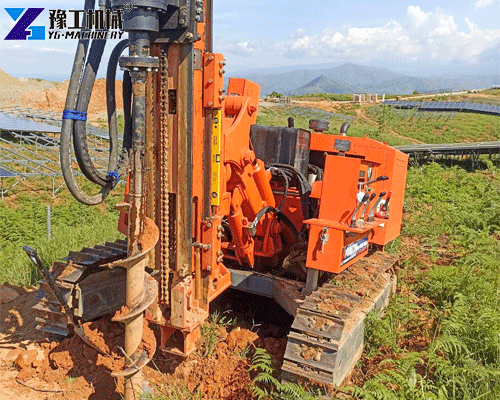

- Crawler chassis for uneven terrain and soft ground

- Adjustable mast angle for slope and complex site conditions

- Compact structure, easy transportation, and fast setup

- Low noise and minimal vibration during operation

These features make the machine suitable for both large-scale solar farms and small distributed PV projects.

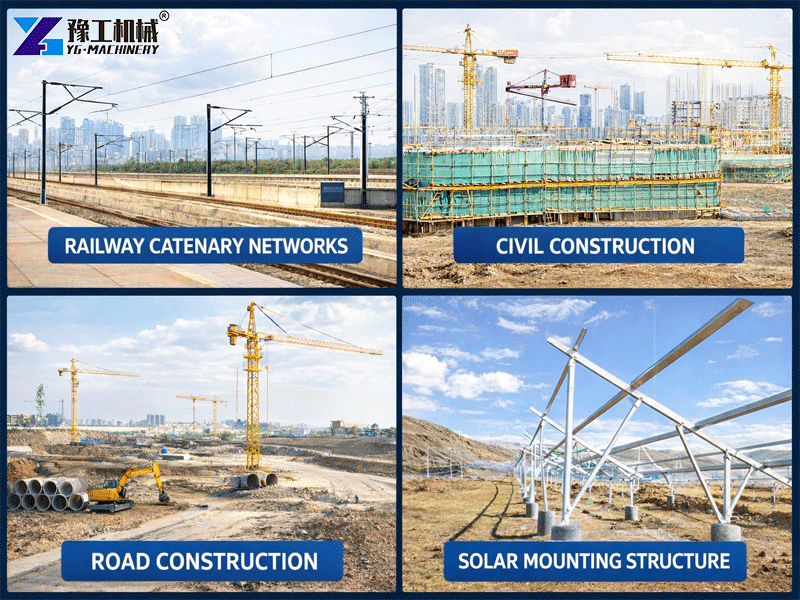

Application of Ground Screw Pile Driver

A solar screw pile driver is widely used in:

- Ground-mounted solar power plants

- Utility-scale photovoltaic projects

- Agricultural solar installations

- Temporary or removable solar structures

- Remote solar sites with limited concrete access

The screw pile foundation is especially suitable for projects requiring fast deployment, environmental protection, and future dismantling.

Solar Screw Pile Driver vs Traditional Pile Driving Methods

Choosing the right piling method directly affects construction speed and total project cost.

Solar Screw Pile Driver Advantages:

- No concrete foundation required

- Faster installation and commissioning

- Easy pile removal and recycling

- Lower environmental impact

- Suitable for various soil conditions

Traditional Hammer or Concrete Foundations:

- Longer construction cycle

- Higher labor and material costs

- Noise and vibration impact

- Difficult to remove after installation

For solar projects with tight schedules and environmental constraints, screw pile installation offers a clear advantage.

Difference Between Screw, Drilling, and DTH Solar Pile Drivers

YG provides multiple piling solutions to suit different geological conditions:

- Solar Screw Pile Driver

Best for soft soil, clay, and medium-density ground. Ideal for standard PV ground screws. - Rotary Drilling Solar Pile Driver

Suitable for harder soil layers or mixed ground. Uses auger drilling before pile placement. - DTH (Down-the-Hole) Solar Pile Driver

Designed for hard rock and high-strength formations. Requires an air compressor for rock breaking.

Selecting the correct piling machine ensures installation efficiency and foundation safety.

Why Choose YG solar screw pile driver machine?

YG Machinery specializes in photovoltaic foundation equipment with extensive export experience.

- Proven performance in global solar projects

- Customizable torque, mast height, and piling depth

- Stable hydraulic systems for long-term operation

- Technical support and after-sales service available

YG solar screw pile drivers help contractors reduce installation time while ensuring reliable foundation performance.

FAQ about Screw Pile Driver

Q: What soil types can a solar screw pile driver handle?

A: It is suitable for clay, sand, loam, and moderately weathered rock, depending on torque and pile design.

Q: Does a solar screw pile driver require an air compressor?

A: No. Screw pile drivers rely on hydraulic rotary torque and do not require compressed air.

Q: How fast is screw pile installation?

A: Installation typically takes a few minutes per pile, depending on soil conditions and pile depth.

Contact YG for Solar Screw Pile Solutions

YG provides professional solar screw pile drivers and complete photovoltaic foundation solutions. Contact us to select the most suitable piling machine for your solar project.【WhatsApp/WeChat/Phone】+86 13837115193.