The threaded rebar coupler plays an essential role in modern reinforced concrete construction. It offers a strong, efficient, and cost-effective way to join steel bars, eliminating the need for lap splicing or welding. Designed to connect two rebars in line, this mechanical connector provides a full-strength joint and ensures structural integrity. People widely use it in bridges, high-rise buildings, tunnels, and other civil engineering projects due to its ease of installation, high tensile performance, and environmental friendliness.

Threaded Rebar Coupler Specifications

| Rebar size | D16mm | D18mm | D20mm | D22mm | D25mm | D28mm | D32mm |

| Outer Diameter (mm) | 24 | 27 | 31 | 33 | 37 | 41 | 47 |

| Length (mm) | 40 | 45 | 50 | 55 | 60 | 65 | 70 |

| Thread Pitch | 2.5 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.0 |

| Thread Angle(degree) | 60/75 | 60/75 | 60/75 | 60/75 | 60/75 | 60/75 | 60/75 |

| G/W(KGS) | 0.076 | 0.110 | 0.176 | 0.207 | 0.275 | 0.365 | 0.515 |

A rebar thread rolling machine precisely machines each coupler to fit the external threads formed on the rebar ends. The outer diameter, thread pitch, and thread angle are all designed to meet industry standards, ensuring a tight, secure connection under tension or compression.

The actual rebar coupler price depends on the size, material, and order quantity. Suppliers often price larger purchases by weight to offer greater affordability. As a leading rebar coupler manufacturer, YG Machinery provides full-size support and custom production services to meet project-specific requirements.

How Rebar Splice Couplers Work?

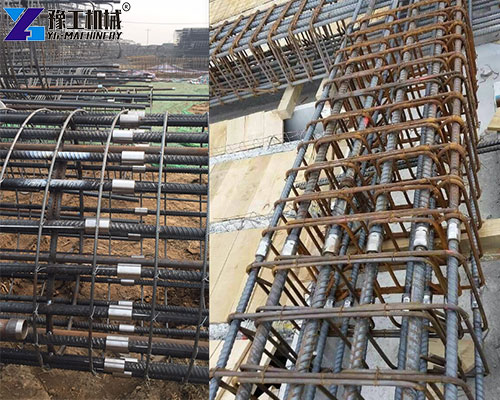

Before installation, workers peel off the ribbed ends of the rebars and thread them using a rolling machine. They then screw the threaded ends into the coupler, forming a solid mechanical connection. This method, often referred to as rebar splice coupler technology, ensures that the joint meets or exceeds the tensile strength of the original bar. Because the machine cold-rolls the threads, it enhances both surface hardness and strength.

This technique is especially useful in scenarios where traditional lap splicing is impractical, such as limited construction space or high-rebar density zones.

Key Advantages of Rebar Splice Couplers

1.High Strength & Reliability: The joint strength is equal to or even greater than that of the base rebar, ensuring excellent axial load transfer. As a result, it provides superior performance and reliability under stress.

2.Efficient Construction: Prefabrication of couplers in the factory allows for fast, easy installation on-site.

3.No Welding or Flame Work: Reduces labor complexity and enhances job site safety.

4.Cost Savings: Less steel waste and lower labor requirements compared to lap splicing or welding.

5.Easy Inspection: Joint quality can be visually confirmed by checking the rebar teeth exposed at the joint.

These features make it ideal for both seismic and non-seismic reinforced concrete applications, including bent or overlapped rebar and congested reinforcement zones.

Applications of Threaded Rebar Coupler

They are commonly used in high-rise buildings, bridge piers, industrial structures, tunnels, power plants, and transportation infrastructure. Their versatility and load-bearing capability make them suitable for static and dynamic load conditions. In addition, They also perform well in extreme environments, such as coastal or marine structures, where corrosion resistance is critical.

YG Machinery-Your Trusted Rebar Coupler Manufacturer

As a professional rebar coupler manufacturer, YG Machinery is committed to providing durable, precise, and competitively priced solutions for all your rebar connection needs. Whether you need a few samples or a bulk supply, our team is here to support your project with rapid delivery and comprehensive technical guidance. Additionally, YG offers a broad range of related construction equipment to complement your needs, including rebar thread rolling machines, steel bar upsetting machines, rebar bending machines, stirrup bending machines, hydraulic punching and shearing machines, rebar straightening and cutting machines, and more.

Contact us today for a free quote.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.