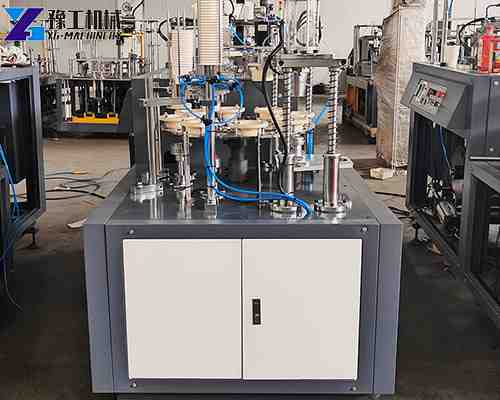

Disposable paper cup making machine is a specialized equipment for producing disposable paper cups, which is suitable for hot drink, cold drink cups, advertising paper cups and other application scenarios. With a high degree of automation and easy operation, this equipment is suitable for cafes, beverage stores, packaging companies and start-up investors, especially for small factories or start-up projects.

YG Disposable Cup Machine Parameters

| Model | YG-DP10 | YG-DP16 | YG-GS120 |

| Production Speed (pcs/min) | 80-110 | 70-90 | 100-120 |

| Voltage | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase |

| Paper Cup Specifications (oz) | 3oz-12oz | 3oz-16oz | 3oz-16oz |

| Machine Package Size (L*W*H, mm) | 2150x1100x1750 | 2150x1100x1950 | 2180x1050x1600 |

| Paper Stock / Material Requirements | 160-350g Single & Double PE Coated Paper | 160-350g Single PE Coated Paper | Single & Double Coated Paper |

| Power (KW) | 7.8KW | 5.5KW | 7KW |

| Weight (Kg) | 1700Kg | 1600Kg | 2100Kg |

| Appropriate customer groups | Start-ups or individuals | Small and medium-sized factories | Big factory |

| Paper Thickness Requirements (g/㎡) | 150-350g/㎡; ±20g/㎡ | ||

| Gas Supply Requirements | 0.6-0.8Mpa; 0.4m³/min | ||

| Cup Body Sticking Method | Ultrasonic Heating | ||

| Bottom Heating Method | Nest Bottom Heating (5 groups) | ||

| Molds Customization | Customizable According to Customer Requirements |

Simple mold replacement, skilled technician can finish it in 3-5 hours, suitable for quick switching of different cup types. The whole machine includes steps of paper feeding, sealing, heating, bottom punching, rimming and demolding to realize the complete paper cup production process.

Production Line Configuration and Advantages

By purchasing YG’s disposable paper cup making machine, customers don’t need to purchase matching equipment separately. We provide the whole production line: paper cup machine + air compressor + raw material (single/double PE lamination paper), which is a mature program with high cooperation, cost saving and shorten the payback cycle. The equipment supports 7oz, 12oz and other common specifications, 1 ton of 190gsm paper can produce about 290,000 7oz paper cups, the return on investment is obvious.

The difference between the standard version and the high version of the equipment is mainly in the degree of intelligence and quality of parts: the high version is equipped with waste removal, pre-feeding, double hot air system and other functions to reduce manual intervention and improve the level of automation and finished product rate.

Frequently Asked Questions

- How many cups can be produced from 1 ton of paper? Approximately 290,000 7oz cups (190gsm paper).

- Is it complicated to change molds? The process of changing the mold is simple and can be done by a technician in about 3-5 hours.

- What are the export countries? More than 30 countries, the main customers are located in Europe, South America, Middle East and some African countries.

Why choose YG Machinery?

As a paper cup machine supplier with 18 years of experience in the industry, YG Machinery has successfully landed many production lines in the United Arab Emirates, Kosovo, Kenya, etc. Customers’ feedback is that the equipment has stable performance, easy operation and fast return on investment. Our team provides a full range of services from equipment selection, mold customization, raw material recommendation to production plan design to help customers start a business easily.

YG Machinery can also customize paper cup printing machine, fully automatic paper cup machine, die-cutting machine, paper plate machine, paper bowl machine and other equipment to meet diversified production needs. Welcome to inquire for exclusive quotation and equipment video demonstration! WhatsApp/WeChat/Phone/Skype】+86 13837115193.