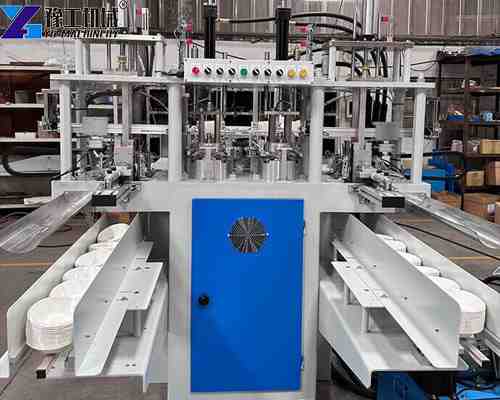

Automatic paper plate machine is an efficient machine designed for producing disposable cup plate and aluminum foil cup plate. It integrates the functions of automatic paper feeding, heating, molding, counting and paper collecting in one machine, which is suitable for food, fast food, cold drink and other industries. According to different molds, a variety of specifications and shapes of round, square or shaped paper trays can be produced to meet diversified market demands. With the advantages of easy operation, high consistency of finished products and fast production efficiency, the machine is widely favored by customers in Kazakhstan, Uganda, Italy and other countries.

Automatic Paper Plate Making Machine Parameters

| Production capacity | 50-85 pcs/min |

| Paper specification | 100-400 g/smBase paper, cardboard, or other |

| Plate specification | 5inch-9inch |

| Voltage | 220V/380V, 50HZ, 3KW |

| Air supply compression | Air pressure: 0.8 Mpa, Air out-put: 0.2 cbm/min |

| Air compressor | Air pressure: 0.5-0.6 Mpa, Air out-put: 0.8 cbm/minCylinder: 150m |

| Packing size | 2500*800*1300mm |

| Weight | 800kgs |

Fully Automatic Paper Plate Machine Features

- Adopting PLC touch control system with fast hydraulic drive, easy to operate, precise size of finished products and low scrap rate.

- It is equipped with thermostatic control, automatic counting, double-sided heating and other functions, which greatly improves the stiffness and beauty of the paper plate.

- The machine adopts mechanical paper feeding method, which is more stable than the traditional paper feeding technology, and the scrap rate is greatly reduced.

- It has many functions such as automatic paper feeding, heating and molding, constant temperature control, automatic counting and so on.

- The machine can be equipped with packaging machine, labeling machine and other equipments to meet the high volume automated production.

Customer Case

- In Kazakhstan, Customer A purchased two automatic paper plate making machines for the production of paper plates for a local fast food chain. The daily production capacity was increased by 35% after the equipment was put into operation, which greatly relieved the order pressure and successfully expanded the new takeaway packaging market. The customer is very satisfied with the stability of the equipment and the quality of the finished products.

- Uganda customer B mainly serves the local supermarket and take-away market, and is particularly concerned about the energy-saving effect of the equipment; YG’s equipment operates stably and consumes low power, reducing the average daily energy consumption by more than 20%, which is fully adapted to the local power conditions, effectively controlling the operating costs, and the equipment is easy to operate, so that the staff training cycle is greatly shortened.

- Italian customer C, focusing on high-end dessert and cake packaging, customized the automatic paper plate making machine with shaped molds, and successfully produced unique and exquisite paper plates after production, which enhanced the added value of the products, and gained the recognition of many high-end dessert stores, and increased the monthly sales by more than 15%, and the customer plans to purchase additional new models.

Safety and Operation Tips

When operating the automatic paper plate making machine, you should pay attention to the following points to ensure personal safety and stable operation of the machine:

- Check that the circuit is well grounded before turning on the power;

- Do not dismantle the protective cover during operation;

- Check the hydraulic system regularly to prevent oil leakage;

- Ensure that the mold replacement operation is carried out in the state of power failure.

Automatic Paper Plate Machine Price Reference

The price varies according to the configuration, automation degree, mold complexity, etc. YG offers a wide range of machines from standard to high speed and customized molds to meet different budgets and production needs. Please feel free to contact YG’s professional team for an accurate quote.

Fully Automatic Paper Plate Machine Price in YG

As a well-known paper container equipment manufacturer in China, YG Machinery is committed to providing global customers with high quality, low price, technologically advanced fully automatic paper plate machine and complete paper products production line. We continuously optimize product design and enhance automation level to help customers stand out in the competitive market.

YG also produces the following products: paper cup roll die-cutting machine, flexo paper cup printing machine, high speed paper cup machine, paper cup die-cutting machine, toilet paper production line, paper cup machine, and so on. Welcome to contact us for free program design and equipment quotation. WhatsApp/WeChat/Phone/Skype】+86 13837115193.