In October 2025, a construction contractor from Poland purchased a YG-ZP30 laser screed for sale from YG Machinery to complete a large-scale warehouse flooring project. The client faced challenges with uneven concrete surfaces and slow manual leveling, which often resulted in low productivity and inconsistent flatness. After using the YG concrete laser screed, the problem was fully solved, and the client reported that both the leveling accuracy and project speed improved significantly.

Laser Screed for Sale Parameters

| concrete laser screed | YG-CL300 | YG-CL300A | YG-ZP30 | YG-ZP40 | |||

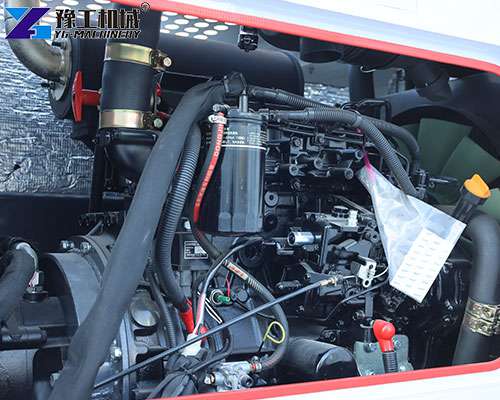

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Engine brand model | Yanmar 4TNV94L | Yanmar 4TNV98L | ||

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Type | Diesel | Diesel | ||

| Engine power | 22KW/30ps | 22.8KW/23ps/31ps | Power | 35.5KW/48hp | 63.9KW/86hp | ||

| Fuel capacity | 20L (operation time is about 8 hours | 20L (operation time is about 8 hours | Fuel tank volume | 100L | 140L | ||

| Hydraulic oil capacity | 37L | 35L | Hydraulic oil volume | 150L | 200L | ||

| Laser transmitter | Swiss Leica/Tower transmitter (optional) | Swiss Leica/Tower transmitter (optional) | Hydraulic system | Danfoss | Danfoss | ||

| Laser receiver | Swiss Leica/Tower receiver (optional) | Swiss Leica/Tower receiver (optional) | Laser transmitter | American Tempo | American Tempo | ||

| Laser system control effect | Plane, slope, double slope (three-dimensional) | Plane, slope, double slope (three-dimensional) | Laser receiver | German Mopar | German Mopar | ||

| Laser system control method | Microcomputer laser scanning | Microcomputer laser scanning | Laser system control effect | Flat, inclined or double slope (3D) | Flat, inclined or double slope (3D) | ||

| Paving method | Hydraulic stirring cage paving | Hydraulic stirring cage paving | Laser system control method | Microcomputer laser scanning | Microcomputer laser scanning | ||

| Vibration method/excitation force | Hydraulic vibration/2000N | Hydraulic vibration/2000N | Trapping method | Hydraulic Cage Paving | Hydraulic Cage Paving | ||

| Vibration plate width | 2500mm | 3000mm | Auger power | Hydraulic motor | Hydraulic motor | ||

| Leveling thickness | 50-300mm | 60-300mm | Advantages of Jiaobanlong | Flip up and down for easy cleaning, left and right switching, blades made of highly wear-resistant material, more durable | Flip up and down for easy cleaning, left and right switching, blades made of highly wear-resistant material, more durable | ||

| Travel drive | Reducer motor integrated | Reducer motor integrated | Reach length | 6000mm | 6000mm | ||

| Travel speed | 0-4Km/h (speed adjustable) | 0-4Km/h (speed adjustable) | Vibrating plate width | 3100mm | 4000mm | ||

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) | Solid anti-skid and anti-puncture tires (optional wide tires) | Leveling thickness | 100-450mm | 100-500mm | ||

| Body size | 3250x2850x1320mm | 3300x3460x1650mm | Walking weight/working speed | 4-8km/h 24m/min | 4-8km/h 24m2/min | ||

| Body weight | 900Kg | 1000Kg | Walking drive form | Hydraulic four-wheel drive Outrigger | Hydraulic four-wheel drive Outrigger | ||

| Steering method | One-touch four-leg self-leveling | One-touch four-leg self-leveling | |||||

| Walking tires | Front wheel + four wheels + crab walk | Front wheel + four wheels + crab walk | |||||

| Cleaning machine flow | 15L/min | 15L/min | |||||

| Body size | 5350x3650x2040mm | 5495x4555x2630mm | |||||

| Weight | 5500 kgs | 8500 kgs | |||||

Poland’s Growing Demand for Laser Screed Machines

In recent years, Poland has experienced rapid growth in industrial construction — including logistics warehouses, shopping centers, and large-scale production facilities. Contractors are increasingly looking for laser concrete leveling machines that can deliver high precision and efficiency.

However, most Polish companies still face common issues such as:

- Uneven concrete finishes due to manual leveling;

- High labor costs and long project timelines;

- Lack of advanced laser screed machine suppliers locally.

That’s why many contractors are now turning to YG’s laser screed for sale as a reliable, cost-effective solution.

YG’s Solution: High Precision Meets High Efficiency

After understanding the Polish client’s project requirements, YG recommended the following models of laser screed machines:

Each laser screed machine model is designed with advanced microcomputer laser scanning control, ensuring accurate self-leveling and uniform concrete surfaces. YG’s machines also feature hydraulic drive systems and adjustable vibration frequency, allowing precise operation even on complex construction sites.

Customer Feedback of Concrete Laser Screed from Poland

After several weeks of use, the Polish client reported outstanding results:

“The YG concrete laser screed has transformed our workflow. The surface finish is smooth, consistent, and perfectly level. Our team can now complete a full warehouse floor in half the time compared to before.”

This feedback demonstrates YG’s strong commitment to delivering not only machines but also reliable performance and after-sales support.

Why Polish Contractors Choose YG Laser Screed Machines?

- Precision leveling: Laser-guided control ensures ±2mm accuracy.

- High efficiency: One machine replaces multiple workers, saving time and cost.

- Durable design: Heavy-duty steel structure suitable for European climate conditions.

- Easy operation: Hydraulic and electric control systems simplify handling.

- Excellent service: YG provides full technical support and spare parts supply.

FAQ about Laser Screed Machine from Polish Clients

Q1: What is the price range of YG laser screed for sale?

A1: Prices vary by model and configuration, depending on the control system and working width.

Q2: Can the laser screed machine work in cold Polish winters?

A2: Yes. YG’s machines are built with weather-resistant materials and can operate effectively in low temperatures with proper maintenance.

Q3: How long does it take to learn how to operate a concrete laser screed?

A3: Most operators can master the machine within 1–2 days of basic training. YG also provides video tutorials and online support.

Q4: Do you provide after-sales service to Poland?

A4: Absolutely. YG offers online technical guidance, spare parts delivery, and long-term maintenance support for all international clients.

Concrete Laser Screed in Yugong Machinery

The successful delivery of YG’s laser screed for sale to Poland demonstrates how precision engineering can revolutionize modern construction. With advanced technology, stable performance, and excellent after-sales support, YG Machinery has become one of the most trusted laser screed machine suppliers for global contractors.

If you’re looking for reliable road machinery such as concrete laser screeds, road rollers, road marking machines, crack filling machines, excavators, etc., contact YG Machinery today for a free quote and technical consultation.