As global fast food consumption continues to rise, burger box machine solutions have become a key investment for packaging manufacturers and food service suppliers. From small local factories to large-scale packaging plants, this equipment plays a critical role in producing consistent, hygienic, and cost-effective paper food containers for takeaway and delivery.

This article explains why burger box machines are increasingly popular, how they are used in real production environments, and shares a Mexico customer case to illustrate real-world performance and ROI.

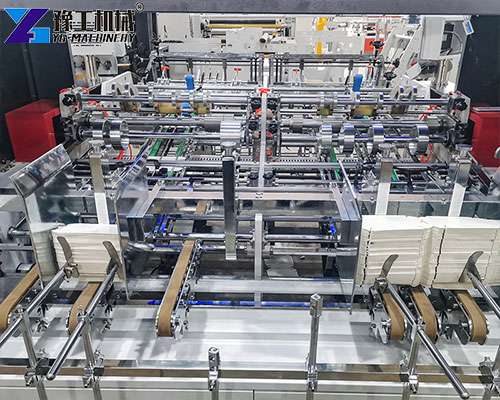

Burger Box Machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

Why Burger Box Machine Is in High Demand?

- Fast Food and Takeaway Consumption Keeps Growing

In markets such as Mexico, the United States, and Latin America, burgers remain one of the most consumed fast food items. The rapid expansion of:

- quick-service restaurants (QSRs),

- food trucks,

- takeaway and delivery platforms

has driven strong demand for standardized paper burger boxes produced by efficient fast food packaging machine systems.

- Shift from Plastic to Paper Packaging

Environmental regulations and consumer awareness are pushing food brands to replace plastic containers with paper-based solutions. A modern burger box machine is designed to work with:

- food-grade kraft paper,

- coated paperboard,

- biodegradable and recyclable materials.

This makes it a core piece of equipment within any paper food container machine production line.

- High Efficiency with Low Labor Cost

Compared with manual folding or semi-automatic equipment, a burger box machine offers:

- stable output of thousands of boxes per hour,

- consistent box shape and locking structure,

- operation by one worker.

For factories facing rising labor costs, this automation advantage is a major reason behind its popularity.

Common Application Scenarios of Burger Box Machine

A burger box machine is not limited to burger packaging. By changing molds, it can be used as a lunch box forming machine and serve multiple segments:

Fast Food Chains

- Burger boxes

- Combo meal packaging

- Standardized takeaway containers

Food Trucks and Street Food Businesses

- Lightweight and foldable boxes

- Easy stacking and transport

- Heat-resistant paper containers

Central Kitchens and Catering Services

- Lunch boxes for bulk meal delivery

- Disposable food containers for schools and factories

Packaging Distributors

- Supplying local brands with customized paper food containers

- Supporting short delivery cycles and flexible orders

Mexico Case: Burger Box Machine for Local Fast Food Packaging Factory

In early 2024, a packaging factory in Monterrey, Mexico invested in one burger box machine to serve regional fast food brands and independent burger shops.

Customer Background

- Previously outsourced burger box supply

- Faced unstable quality and long delivery times

- Wanted in-house production to reduce cost and improve control

Solution Provided

The factory selected a burger box machine that:

- works with food-grade kraft paper,

- integrates smoothly with their existing fast food packaging machine line,

- allows quick mold changes for different box sizes.

Production Results

- Average output: 6,000–8,000 boxes per hour

- One operator per shift

- Stable performance during peak weekend orders

ROI Feedback

After three months:

- Packaging cost reduced by over 30%

- Faster response to local restaurant orders

- Expanded product range using the same machine as a lunch box forming machine

The customer later added logo printing upstream, turning the system into a complete paper food container machine solution.

Current Market Situation and Future Outlook

The global market for burger box machine equipment is shifting toward:

- higher automation,

- compatibility with eco-friendly materials,

- flexible production for small and medium factories.

In emerging markets like Mexico and Latin America, demand is driven not only by fast food chains, but also by local brands seeking cost control and supply stability.

Manufacturers that invest early in reliable burger box machines gain:

- lower unit packaging cost,

- stronger customer retention,

- better margins during peak seasons.

Burger Box Machine in YG Machinery

A burger box machine is no longer just a single-purpose device. It is a versatile, high-efficiency solution that fits perfectly into modern fast food packaging machine lines. Whether used for burger boxes, takeaway containers, or as a lunch box forming machine, it provides real operational and economic advantages.

For packaging factories and food service suppliers, investing in a paper food container machine today means gaining long-term competitiveness in a fast-growing market.