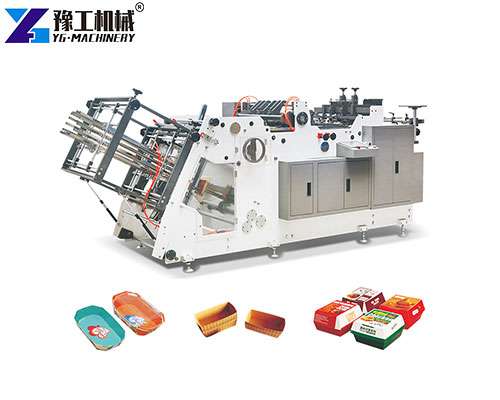

The hamburger box making machine has become one of the most popular pieces of equipment in the fast-food packaging industry. As global demand for eco-friendly, durable, and high-capacity food containers grows, more restaurants, packaging factories, and fast-food brands are investing in automatic burger box machines to improve efficiency and reduce costs.

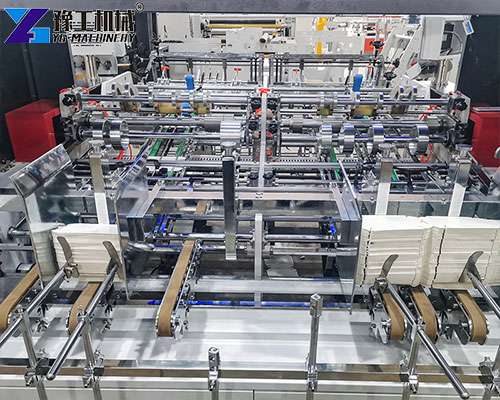

Hamburger Box Making Machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | ||||

Why the Hamburger Box Making Machine Is So Popular?

There are several reasons why more international clients are choosing the hamburger box making machine:

- High-Speed Production

Modern machines can produce thousands of boxes per hour, making them ideal for medium and large packaging factories. High-speed output ensures stable supply during peak seasons.

- Eco-Friendly Material Compatibility

The machine works with kraft paper, coated cardboard, biodegradable paper, and food-grade materials. This makes the paper burger box machine suitable for brands focusing on sustainability.

- Consistent Quality & Strong Box Structure

Automatic forming ensures every hamburger box has good rigidity, clean edges, and oil-resistant performance—important for burgers, fried food, and takeaway packaging.

- Labor Saving

Fully automatic feeding, heating, molding, and stacking reduce the need for manual labor. One operator can manage multiple machines.

Common Usage Scenarios of Burger Box Machine

The hamburger box making machine is widely used across the food packaging industry, including:

- Fast-food chains (burgers, fried chicken, sandwiches)

- Paper packaging factories

- Takeaway food suppliers

- Disposable food container manufacturers

- Restaurants upgrading from manual to automated production

Its compatibility with various box styles makes it an ideal fast food packaging machine for businesses aiming to scale their production.

Investment Benefits and ROI

Purchasing a hamburger box making machine brings clear financial advantages:

- Quick Return on Investment

Many factories report recovering their investment within 6–12 months due to high output and reduced labor.

- Low Operating Costs

Paper material is affordable and the fully automatic system reduces waste, delivering 15–30% savings compared to manual box forming.

- Long-Term Reliability

Stable performance, long service life, and easy maintenance make it a cost-effective choice for long-term production.

- Expanding Market Demand

Demand for food packaging boxes continues to grow, especially in fast food, delivery services, and eco-friendly packaging sectors.

To maximize ROI, some factories expand their production with additional equipment like a paper cup machine for beverage packaging and a digital printing machine for custom logo printing.

Mexico Case Study – Real Customer Success

A packaging factory in Mexico recently invested in a hamburger box making machine to expand fast-food packaging production. Before purchasing, the factory relied on manual forming, which was slow and inconsistent. After installation:

- Production capacity tripled

- Labor costs decreased significantly

- Box quality improved, especially in oil resistance

- The client began supplying local burger shops and fast-food franchises

The customer reported smooth operation and appreciated the machine’s ability to work with recyclable kraft paper—an important trend in the Mexican packaging market.

This successful case shows how a burger box machine can support growing demand in North America’s fast-food industry while maintaining high quality and efficiency.

Hamburger Box Making Machine in YG Machinery

The hamburger box making machine is an ideal upgrade for factories and businesses aiming to produce high-quality food containers at scale. With benefits such as high output, eco-friendly material compatibility, and excellent ROI, it stands out as a leading fast food packaging machine for global markets.

Whether you are supplying local restaurants or managing a large packaging plant, investing in a paper burger box machine can significantly boost your competitiveness and production capacity.