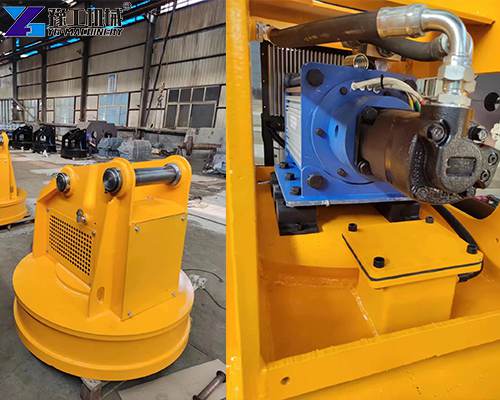

The YG hydraulic magnet for excavators is a high-efficiency magnetic device specifically designed for excavators, enabling fast and safe handling of steel and metal scrap. Powered by a hydraulic system, it delivers strong and stable magnetic force, effortlessly attracting heavy metal objects to enhance construction and recycling efficiency.

Hydraulic Magnet Parameters

| Parameter | STP1200 | STP1200T | STP1300 | STP1300T |

| Weight (kg) | 1750 | 1850 | 1900 | 2050 |

| Dimensions (mm) | 1200*1200*1150 | 1400*1200*1150 | 1300*1300*1150 | 1500*1300*1150 |

| Magnetic Force (gs) | 6000 (8000) | 6000 (8000) | 8000 (10000) | 8000 (10000) |

| Working Pressure (Mpa) | 200 | 200 | 200 | 200 |

| Flow Rate (L/min) | 60 | 60 | 100 | 100 |

| Power (W) | 15000 | 15000 | 20000 | 20000 |

| Voltage (V) | 100-500 | 100-500 | 100-500 | 100-500 |

| Excavator Weight (T) | 18-25 | 20-30 | 25-35 | 25-35 |

Key Features of Hydraulic Magnet

- Powerful Magnetic Adhesion: Utilizes high-performance magnets to attract steel materials of various sizes and weights.

- Hydraulic Drive Control: Operated via the excavator’s hydraulic system, ensuring flexible magnetic switching and rapid response.

- Durable Design: Constructed with high-strength steel plates and corrosion-resistant treatment, suitable for harsh construction environments.

- Simple Operation: Requires no external power source, integrates directly with excavators to reduce construction complexity.

- Multiple Specifications Available: Customizable sizes and magnetic force levels based on excavator models and lifting requirements.

Application Scenarios of Excavator Magnet

- Scrap Recycling

Attracts and transports scrap steel and iron, boosting recycling efficiency while reducing labor costs. - Construction Sites

Clears metal debris from work areas, ensuring a safe construction environment. - Steel Processing Plants

Handling steel plates, pipes, and heavy metal components to boost production line efficiency. - Ports and Logistics

Unloading steel cargo from vessels for rapid transshipment and enhanced operational efficiency. - Other Heavy Machinery Auxiliary Operations

Compatible with crawler excavators or trackhoes for swift movement of large metal objects.

NSW, Australia Customer Case Study

In 2025, a New South Wales-based scrap recycling company purchased the YG hydraulic magnet for excavator to handle scrap steel transportation and site clearance.

- Efficiency Boost: Daily scrap steel handling increased by 50% compared to manual operations, significantly reducing task duration.

- Operational Ease: Staff quickly mastered magnetic control, minimizing safety risks.

- Equipment Stability: Operated continuously for over 6 months without major malfunctions.

Customer Feedback: “The YG magnet for excavators not only boosted production efficiency but also ensured construction safety. It’s one of our most worthwhile investments.”

FAQs about Magnet for Excavator

Question 1: Which excavator models are compatible with the hydraulic magnet?

Answer: Suitable for most medium to large excavators and tracked equipment. Mounting interfaces can be customized as needed.

Question 2: What weight of steel can the magnet lift?

Answer: Depending on the model, it can lift steel materials ranging from 500kg to 5000kg, meeting industrial handling demands.

Question 3: Is operation complicated?

Answer: Controlled directly via the excavator’s hydraulic system without requiring an external power source, ensuring simple operation.

Question 4: Is the equipment suitable for long-term outdoor operation?

Answer: Constructed with corrosion-resistant treatment and high-strength steel plates, it withstands rain, dust, and high-temperature environments.

Maintenance and Care Guidelines

To ensure long-term stable operation and extend the service life of the YG hydraulic magnet for excavators, customers should observe the following during daily use:

- Hydraulic System Inspection

Regularly check hydraulic lines for leaks or loose connections to maintain stable pressure.

Avoid hydraulic oil contamination or use of non-compliant hydraulic fluids. - Magnet Surface Cleaning

After each operation, clean metal debris and dust from the magnet surface to prevent magnetic strength reduction or scratches. - Fastener Inspection

Periodically check bolts, nuts, and connectors for looseness to ensure secure installation. - Corrosion and Rust Prevention

In humid or coastal environments, apply rust-preventive oil to the magnet surface to extend service life. - Operating Precautions

Ensure magnet deactivation during no-load operation to prevent unnecessary wear or safety hazards.

Do not lift non-metallic objects or exceed rated load capacity to avoid equipment damage. - Regular Maintenance

Conduct comprehensive inspections every 3-6 months, covering hydraulic systems, magnetic performance, and mechanical structure.

Contact manufacturer technical support immediately for repairs if abnormalities are detected.

YG Hydraulic Magnet for Excavators

YG hydraulic magnets for excavators are the ideal choice for industrial and construction clients in NSW, Australia, to boost productivity, reduce labor costs, and ensure operational safety. Whether for scrap recycling, construction cleanup, or steel handling, our excavator magnets and trackhoe magnets deliver stable, efficient solutions. In addition, YG also produces electromagnetic lifting, excavator, contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.