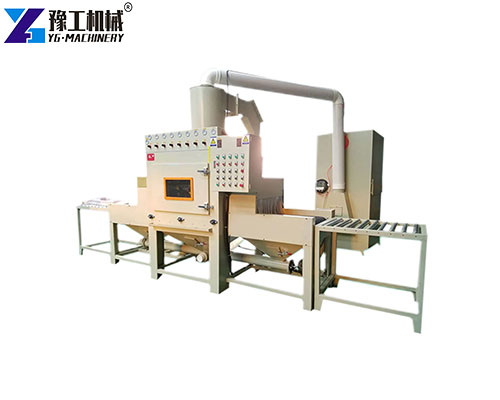

The sand plast machine is a powerful surface treatment device widely used across industries for its ability to clean, deburr, roughen, and improve the adhesion of surfaces. As a core part of abrasive jet technology, this equipment utilizes compressed air to propel various abrasives—such as quartz sand, copper ore, corundum, and glass beads—at high speed, delivering efficient results in metal processing, construction, and more. Whether you need to prepare a surface for painting, remove rust, or polish stone, this machine offers an ideal solution. It’s especially favored for its speed, flexibility, and environmental friendliness when equipped with a dust-control system. YG Machinery provides multiple models, and customers can choose based on their specific needs in diameter, height, volume, and efficiency.

Blasting Painting Equipment Parameters

YG offers various models to suit different project demands. The machines vary in diameter from 400 mm to 1000 mm, heights from 1150 mm to 2000 mm, and air consumption around 3 m³/min. Working pressure typically ranges from 0.4 to 0.8 MPa. This range allows customers to choose an optimized model for their operation.

| Machine models | YG400 | YG500 | YG600 | YG700 | YG800 | YG900 | YG1000 |

| Diameters(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1150 | 1150 | 1150 | 1250 | 1700 | 2000 | 2000 |

| Volume(cubic meter) | 0.26 | 0.26 | 0.26 | 0.3 | 0.6 | 0.8 | 1 |

| Pressure(Mpa) | 0.4-8 | ||||||

| Air consumption(cubic meter per minute) | 3 | ||||||

Working Principle of the Sand Plast Machine

The core operating principle revolves around compressed air. Abrasives are accelerated through a nozzle to impact the target surface. This high-speed collision removes contaminants, enhances surface texture, and can even strengthen the substrate by eliminating residual stress and increasing hardness. As a result, the treated surfaces are not only cleaner but also more suitable for coatings and further processing.

3 Main Types of Sand Plast Machines

- Wet Sand Blasting Machine: This machine mixes abrasive with water before ejection, minimizing dust and making it ideal for precision work. Operators often use it in environments that require fine detail and high cleanliness.

- Suction Dry Blasting Machine: The spray gun creates negative pressure to draw in abrasive, then accelerates it with compressed air. Its simple structure makes it perfect for operators handling light-duty tasks and small-scale jobs.

- Pressure Dry Blasting Machine: This model combines abrasive directly with compressed air inside a pressurized tank, then blasts it at high speed for efficient and powerful cleaning. It is the preferred choice for large-scale or high-intensity applications due to its higher efficiency.

The main distinctions among these lie in their feeding method and the involvement of water, offering users different options depending on the desired surface finish and application scale.

Advantages of Sand Plast Machine

- Efficient Surface Cleaning: The sand plast machine excels at rapidly removing rust, old paint, scale, and oxidation layers. This ensures a clean, contaminant-free surface, essential for high-quality finishing and extended product lifespan.

- Adjustable Roughness: Operators can fine-tune the blasting intensity to achieve different surface textures. Whether preparing for delicate painting and coating preparation or heavy-duty treatments, the machine provides unmatched flexibility and precision.

- Increased Coating Adhesion: By creating a textured surface, the sand plast machine significantly improves the bonding strength for paints and sealants, reducing the risk of peeling or blistering over time. This is critical for long-term durability and weather resistance.

- Improved Mechanical Properties: Blasting helps to relieve residual stress from the material surface, which in turn enhances fatigue resistance and structural integrity—especially important in high-stress applications like metal parts and infrastructure.

- Dust Control (in wet models): The wet sand blasting machine features water-abrasive mixing, effectively suppressing dust and airborne particles. This ensures a safer working environment, especially in enclosed spaces or cleanroom settings.

Application Fields of Blasting Painting Equipment

- Metal Processing: The blasting painting equipment plays a critical role in surface preparation by removing rust, scale, and contaminants. It enhances coating adhesion and surface durability, making metals more resistant to wear, corrosion, and environmental damage.

- Construction and Infrastructure: This equipment is widely used to clean and smooth concrete surfaces, ensuring better bonding for new layers. It also helps restore aged structures and effectively treat stone cracks or imperfections, contributing to structural longevity.

- Mining and Quarrying: In rugged environments, the equipment helps clear dust buildup from heavy-duty machines and unclog processing equipment, reducing downtime and enhancing operational efficiency in harsh mining conditions.

- Polishing and Lubrication: When combined with polishing powders or additives, blasting equipment can refine surface finishes for visual appeal or functional precision, particularly in manufacturing, tooling, and decorative metalwork.

Mobile Options for Greater Flexibility

For users requiring on-site operations, YG also offers mobile sand blasting equipment for sale, providing convenient transport and flexibility without compromising on performance. These units are ideal for contractors and field technicians.

Mobile Sandblasting Equipment for sale in YG Machinery

YG Machinery is a professional manufacturing factory known for its reliable, high-performance sand plast machines. Our team provides comprehensive support from model selection to after-sales service. Whether you’re looking for a wet sand blasting machine or powerful blasting painting equipment, we offer tailored solutions to meet your project goals. In addition to this product, we recommend exploring other top-selling YG equipment, including hydraulic wire saw, stone wire saw, excavator, and hydraulic breaker attachment, etc. We are committed to helping you improve efficiency and quality across your industrial operations. Contact Us Today.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.