In April 2025, a construction company in Tallinn, Estonia, faced an urgent need to demolish a section of a concrete bridge spanning a key transportation route. The challenge? The structure was reinforced with thick steel rebar, sat over active utilities, and any operation had to minimize vibration, dust, and disruption. After evaluating several cutting solutions, the Estonian team chose YG Machinery’s diamond cutting wire saw, marking a successful entry of the product into the Baltic market.

The site manager, Lauri, commented: “We were under pressure to meet safety standards and finish on time. The diamond wire saw from YG gave us precise cuts and excellent speed. There was minimal noise and zero structural disturbance. We couldn’t have done it better.”

This case reflects not only the rising demand for advanced cutting technology in Europe but also the growing recognition of wire cut concrete solutions that prioritize precision, efficiency, and safety.

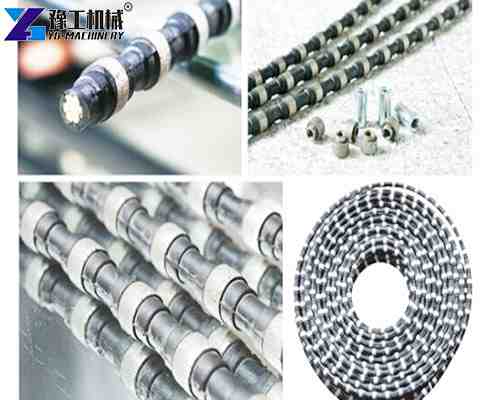

YG Diamond Cutting Wire Saw Specifications

The diamond cutting wire saw model selected for this project was the YG-45HT-6P. Its performance proved ideal for complex, reinforced concrete applications.

| Diamond Wire Saw Parameters | Hydraulic Pump Station Parameters | ||

| Wire drive mode | hydraulic | Rated output power | 22/25kw |

| Mode type | HM-40/80 | Working voltage | 380v50Hz |

| Minimum input power | 25/33HP | Hydraulic pump station | gear pump |

| Output shaft speed | 350/940/1300r/min | Motor working flow | 40-100L/min |

| Maximum wire length | 18m | Working pressure | 15-20Mpa |

| Enter method | fully hydraulic | Oil tank volume | 17L |

| Cutting machine weight | 64kg | Weight | 98kg |

| Motor weight | 14kg | Dimension(mm) | 650*550*1150 |

The machine featured a crawler walking system for flexibility in rugged outdoor terrain and allowed precise, automated feed movement for controlled and continuous cutting.

Estonian Market Needs: Why a Diamond Cutting Wire Saw Was the Right Choice

In recent years, Estonia has invested heavily in urban redevelopment, highway expansion, and port upgrades. With many of these projects involving the removal of reinforced concrete in restricted areas, traditional demolition methods have become less viable.

The customer initially tried hydraulic breakers, but found the vibration caused cracks in nearby structural components. Core drilling was too slow and couldn’t handle embedded rebar. That’s when they turned to the diamond cutting wire saw, drawn by its track record in wire cut concrete solutions around Europe.

How YG’s Solution Addressed the Challenge

YG’s engineering team worked closely with the Estonian client to develop a custom cutting strategy. The compact crawler-mounted saw offered several clear advantages:

- Non-destructive precision: Clean, straight cuts without micro-fractures or rebound forces.

- Low noise and dust: Crucial for the urban setting and compliance with local environmental standards.

- Adaptability: Able to wrap around large columns and cut at varying angles, something circular saws couldn’t do.

- Time savings: Completion time was reduced by 30% compared to the previous method.

Moreover, Lauri noted that the diamond wire saw for concrete performed better than expected, even with embedded rebar and varied concrete densities, reinforcing confidence in YG’s engineering capabilities.

Key Benefits and Application Scenarios

The diamond cutting wire saw stands out due to its unique combination of efficiency, control, and versatility. Here’s where it excels:

- Bridge and highway reconstruction

- High-rise building modification or dismantling

- Water reservoir and dam concrete cutting

- Underwater or difficult-access concrete operations

- Nuclear and chemical plant renovations requiring zero vibration

Compared to hydraulic splitters or wall saws, it provides smoother results and reduces post-processing time.

The Estonian client emphasized another benefit—cost control. Though the initial diamond wire saw price was higher than basic cutting tools, the reduced labor and faster turnaround meant a better ROI.

Why Choose YG Machinery?

YG Machinery is a professional manufacturer of diamond wire saw technology, known for:

- Customizable models to suit local environmental and structural requirements

- Rapid overseas delivery and multilingual technical support

- Durable machines designed to handle high-frequency industrial use

- Proven international track record, including in Europe, Southeast Asia, and the Middle East

Estonia is now among the growing list of satisfied customers who rely on YG’s cutting-edge equipment to meet complex challenges.

Related Equipment Recommendations

In addition to the diamond cutting wire saw, YG also provides: concrete wall saw machines, hydraulic rock breaker machine, electric rope saws, etc. Each of these tools complements the wire saw in different cutting and demolition scenarios, offering a full solution suite for construction professionals. Contact YG Machinery for the latest diamond wire saw price and model availability. [WhatsApp/WeChat/Skype/Phone] at +86 13837115193.