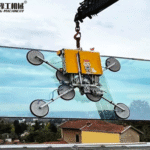

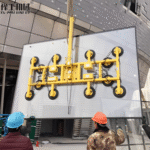

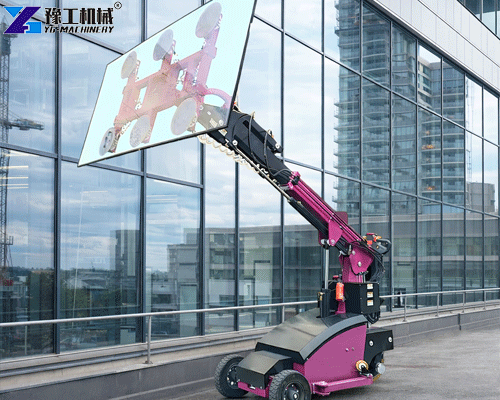

In March 2025, a U.S.-based commercial glazing company in Chicago implemented a glass lifting robot for sale, reporting a 35% improvement in installation efficiency and enhanced worker safety. The machine, also referred to as a glass lifting robot or glazing robot, is designed for automated handling of large glass panels in commercial and industrial construction projects. Its vacuum suction system allows precise lifting, rotation, and placement, reducing manual labor risks.

Customer Challenges in Glass Handling

U.S. glazing contractors often face these challenges:

- Labor shortages: Skilled operators for large panel installation are limited, especially in urban construction projects.

- Safety concerns: Manual glass lifting carries a high risk of breakage and injuries, increasing insurance and liability costs.

- Project delays: Handling large panels manually slows down installation, particularly on high-rise buildings or curtain walls.

In this context, the client needed a reliable solution that could lift panels up to 1,500 kg, rotate precisely, and integrate with cranes or mobile platforms for flexible deployment.

U.S. Market Trends and Glass Handling Needs

American glazing contractors increasingly adopt automation due to labor shortages and safety regulations. On average, projects in major cities like New York, Los Angeles, and Chicago experience 15–25% project delays caused by manual glass handling. The Glass Lifting Robot addresses these delays by:

- Reducing installation time by 30–40% per panel

- Minimizing breakage incidents by 50% compared to manual methods

- Allowing single operators to handle panels that previously required 3–4 workers

Additionally, clients often compare the machine to conventional glazing robots in terms of glazing robot price and operational flexibility. YG provides a detailed cost-performance analysis to help contractors make data-driven decisions.

YG Solutions and Implementation Process

YG Machinery offered a tailored solution:

- Site assessment: Engineers evaluated lifting heights, panel sizes, and site access.

- Custom configuration: Selected vacuum pad arrangement and rotation range suitable for curtain wall installation.

- Integration support: Machine mounted on a mobile crane for high-rise usage.

- Training: On-site operator training ensured proper handling and maintenance.

After deployment, the client reported smooth operation in varying conditions, including windy rooftop installations, with minimal downtime.

| Model Type | YG-LD-300 | YG-LD-400 | YG-LD-500 | YG-LD-600 | YG-LD-800 | |

| Load Capacity | 300kg(retract)150kg(extend) | 400kg(retract)200kg(extend) | 500kg(retract)250kg(extend) | 600kg(retract)300kg(extend) | 800kg(retract)400kg(extend) | |

| Lifting Height | 3500mm | 3500mm | 3700mm | 3700mm | 4500mm | |

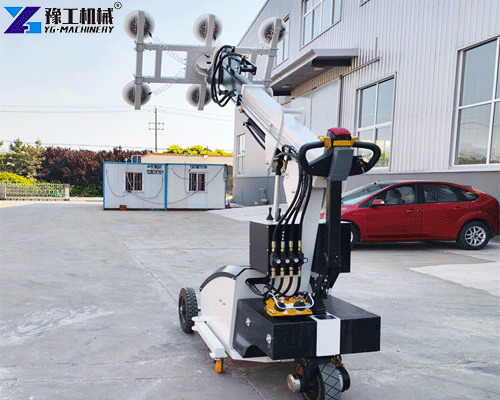

| QTY of Suction Cap | 4pcs | 4pcs | 6pcs | 6pcs | 8pcs | |

| Rubber Suction Cap | 300mm | Ø300mm | Ø300mm | Ø300mm | Ø300mm | |

| Maintenance-free Battery | 2x12V/80AH | 2x12V/100AH | 2x12V/120AH | 2x12V/120AH | 2x12V/120AH | |

| Battery Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | |

| Drive motor | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | |

| Lifting Motor | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/12L | |

| Chassis L*W | 2660*810mm | 2660*810mm | 2800*810mm | 2800*810mm | 2800*810mm | |

| Driving Wheel | Ø250x80mm | Ø250x80mm | Ø300x100mm | Ø300x100mm | Ø300x125mm | |

| Packing Size(mm) | 2560*1030*1700 | 2560*1030*1700 | 2580*1050*1700 | 2580*1050*1700 | 3000*1250*2300 | |

| N.W/G.W | 1100/1150kg | 1280/1330kg | 1300/1350kg | 1400/1450kg | 1600/1650kg | |

| Loading Qty | 1x20GP/40GP: 6SETS/12SETS | |||||

| Movement | Automatic(4 kinds) | 1. The suction cup frame flips 180° electrically. 2. The support plate automatically retracts. 3. Hydraulic arm lifts electrically. 4. The base of the whole machine moves 100-150mm horizontally. | ||||

| Manual (2kinds) | 1. The suction cup holder can be manually rotated 90 degrees (electrically powered optional). 2. The suction cup holder can be manually rotated 360 degrees (electrically powered optional). | |||||

| Usages | Mainly used for the handling, movement, and installation of materials such as glass, marble, wood, iron plate, etc. | |||||

Customer Feedback and ROI

The client highlighted:

- Efficiency: Installation speed increased by 35%.

- Safety: Zero incidents after one month of operation.

- Cost savings: Reduced need for additional labor lowered project costs by approximately 20%.

Feedback also mentioned the ease of using the machine as a glazing robot, noting that it replaced multiple manual lifting tools without complicating workflow.

FAQ about Glass Lifting Robot for Sale

Q1: What affects glazing robot price?

A1: Factors include load capacity, vacuum pad number, rotation capability, and optional mountings for forklifts or cranes.

Q2: Can the glass lifting robot handle oversized panels?

A2: Yes, modular suction pads can be adjusted to fit panels up to 1,500 kg and 3.5 × 2.5 meters in size.

Q3: Is maintenance complex?

A3: Standard battery checks, vacuum pump inspection, and pad replacement are sufficient. YG provides full operation manuals and remote technical support.

Q4: Delivery and training

A4: Typical lead time is 6–8 weeks. On-site training and commissioning are included in the package.

Why YG Machinery is a Trusted Manufacturer?

YG Machinery has over 15 years of experience in automated lifting solutions, exporting to North America, Europe, and Asia. The company emphasizes:

- Engineering precision

- Configurable solutions for diverse site conditions

- Post-sales technical support and spare parts availability

U.S. clients benefit from YG’s comprehensive service, ensuring that glass lifting robot deployments are safe, efficient, and cost-effective. Contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.