In June 2025, a leading mining company in Ghana successfully purchased a rc drilling from YG Machinery to enhance their copper and gold exploration projects. The company needed a reliable, high-efficiency drilling solution capable of handling Ghana’s rugged terrain and complex geological formations. After evaluating several options, they chose YG’s reverse circulation drilling rig due to its cost-effectiveness, precision, and proven performance in West African mining sites.

Client Challenges and Requirements

Ghana’s mining areas often involve hard rock, gravel, and uneven surfaces, which can reduce drilling efficiency and increase operational costs. The client specifically faced these challenges:

- Inconsistent core recovery rates from previous equipment, affecting geological analysis accuracy.

- Limited on-site technical support for imported rigs, causing frequent downtime.

- High operational costs due to excessive fuel consumption and maintenance.

- Need for fast drilling to meet tight project timelines for multiple exploration sites.

They required a rc drilling machine that could overcome these challenges while delivering reliable performance under harsh conditions.

YG RC Drill Rig Solution

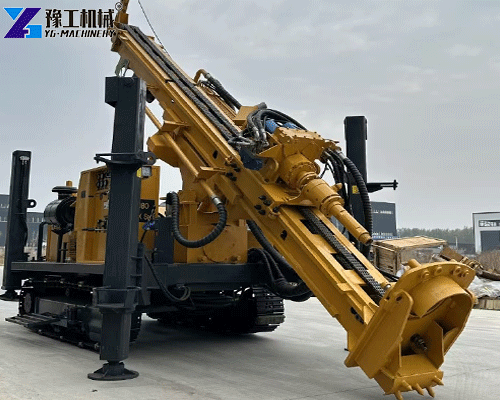

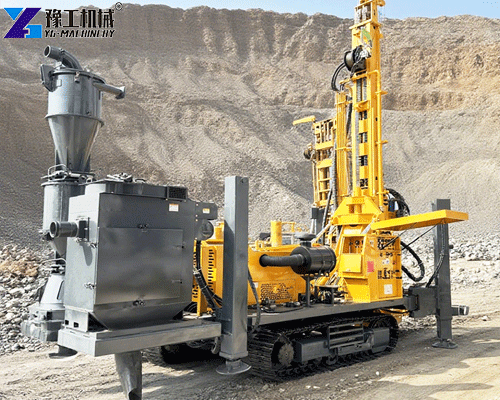

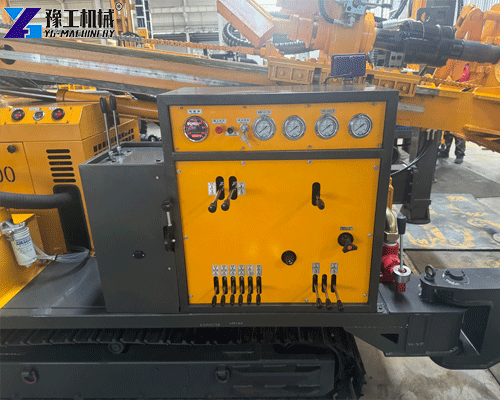

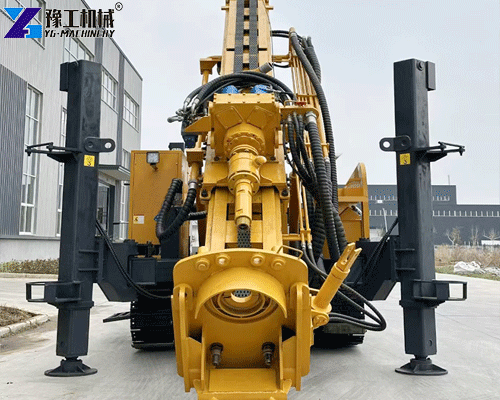

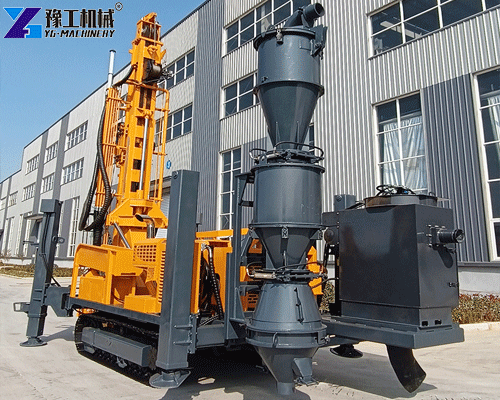

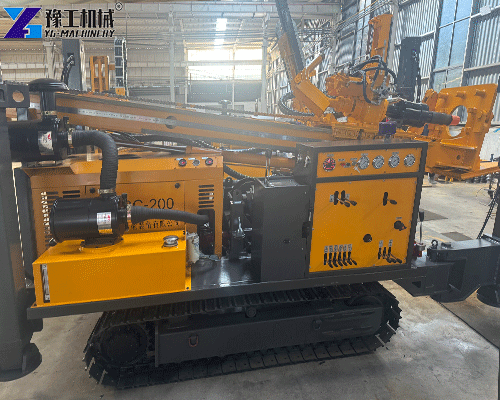

YG Machinery recommended YG400 reverse circulation drilling rig equipped with a hydraulic feed system, dual-motor spindle, and reinforced drill frame. Key specifications included:

| Technical Parameters | Unit | YG-400 | YG-500 | YG-600 | YG-800 | YG-1200 |

| Max drilling depth | m | 400 | 500 | 600 | 800 | 1200 |

| Hole diameter | mm | 105–305 | 105–400 | 105–450 | 105–550 | 105–800 |

| Recommended working pressure | MPa | 1.2–3.5 | 1.6–6 | 1.6–6 | 1.6–8 | 1.6–8 |

| Recommended air consumption | m³/min | 16–55 | 16–55 | 16–75 | 16–96 | 16–96 |

| Drill pipe length | m | 3 | 3 | 3 | 6 | 6 |

| Recommended drill pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| RC double-wall pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| Feed force | T | 6 | 7 | 7 | 11 | 13 |

| Lifting force | T | 22 | 25 | 29 | 47 | 57 |

| Fast lifting speed | m/min | 20 | 23 | 29 | 29 | 30 |

| Fast feeding speed | m/min | 32 | 33 | 33 | 42 | 44 |

| Max rotary torque | Nm | 8000/4000 | 10000/5000 | 12000/6000 | 18000/9000 | 24000/12000 |

| Max rotary speed | r/min | 75/150 | 75/150 | 75/150 | 70/140 | 86/172 |

| Aux winch lifting force | T | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 |

| Mast stroke | m | 1.6 | 1.6 | 1.7 | 1.7 | 1.7 |

| Travel speed | km/h | 10–35 | 10–35 | 10–35 | 10–35 | 10–35 |

| Gradeability | ° | 21 | 21 | 21 | 21 | 21 |

| Machine weight | T | 11 | 12 | 12.5 | 17 | 23 |

| Overall dimensions (L×W×H) | m | 7×1.85×2.86 | 7×2.1×2.9 | 7×2.1×2.9 | 10.5×2.25×3.3 | 11.5×2.25×3.4 |

| Engine | / | Yuchai 92kW | Cummins 132kW | Cummins 132kW | Cummins 194kW | Cummins 264kW |

The rig is designed for high penetration rates, precise core sampling, and low operational downtime. Its modular design allows transport via trailer, suitable for Ghana’s remote sites.

Project Implementation and Performance

The rc rig was deployed across three mining sites in the Ashanti and Western regions. Key outcomes included:

- Efficiency increase: Average drilling speed improved by 25% compared to previous rigs.

- Core recovery: Consistently over 95%, providing reliable samples for mineral assay.

- Operational uptime: The rig ran 1,500 operational hours in 2025 with minimal maintenance.

- Fuel savings: Intelligent hydraulic system reduced fuel consumption by approximately 18%.

According to the client, “The rc drilling from YG Machinery exceeded our expectations in both reliability and drilling precision. It is easy to operate, and maintenance cycles are shorter than previous rigs.”

Why Reverse Circulation Drilling Machines Are Cost-Effective?

Investing in a rc drill rig brings long-term savings due to:

- High core recovery reducing repeat drilling costs.

- Efficient hydraulic feed system minimizing fuel and operational expenses.

- Durable components with easy access to spare parts.

- Quick deployment and mobility, reducing project downtime.

For Ghanaian mining companies, this translates into faster project completion, lower per-meter drilling costs, and higher accuracy in mineral exploration.

Considerations When Choosing an RC Drill Rig

When selecting a reverse circulation drilling rig for sale, clients should evaluate:

- Drilling depth requirements: Match the rig’s maximum depth to the target mineral zones.

- Geological conditions: Ensure the rig handles local rock hardness and terrain.

- Mobility needs: Trailer-mounted or crawler-based rigs improve site transfer efficiency.

- Support and parts availability: YG provides spare parts stock and 24/7 technical support.

- Budget vs. long-term cost: Consider fuel efficiency, maintenance intervals, and core recovery rates.

Choosing the right configuration ensures optimal performance and return on investment.

YG Machinery: Trusted Supplier in West Africa

YG Machinery has supplied liquid core drilling rigs, reverse circulation drilling rigs, and other hydraulic core rigs to Ghana, Cameroon, Burkina Faso, and Zimbabwe for over a decade. Advantages include:

- High-quality components from internationally recognized brands.

- Affordable pricing with a transparent cost structure.

- Comprehensive logistics and delivery ensuring equipment reaches remote mining sites safely.

- Full technical support including on-site training, video tutorials, and online guidance.

These factors make YG a reliable choice for clients seeking rc drilling in Africa.

RC Drill Rig for Sale in YG Machinery

For mining operations in Ghana, the deployment of YG’s rc drilling demonstrated measurable benefits: faster drilling, higher core recovery, and reduced operational costs. The project highlights how a well-chosen rc drilling machine or reverse circulation drilling rig can improve exploration efficiency and profitability. Companies in similar regions can confidently invest in YG’s rigs, knowing they are supported by a factory with proven expertise, full spare parts availability, and strong field performance.