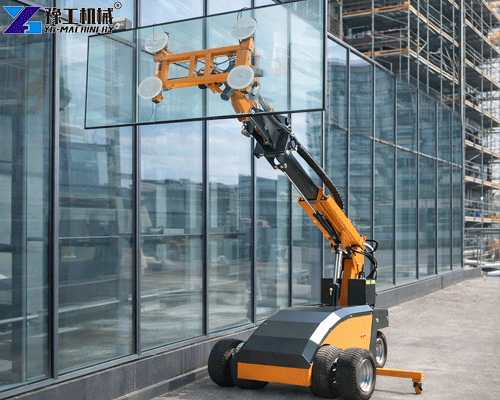

A glazing robot for sale deployed in Spain helped a façade contractor cut glass installation time by 32% while meeting urban safety and efficiency requirements. The solution is designed for precise curtain wall glass positioning, stable vacuum lifting, and controlled movement in confined construction sites.

Glazing Robot Parameters

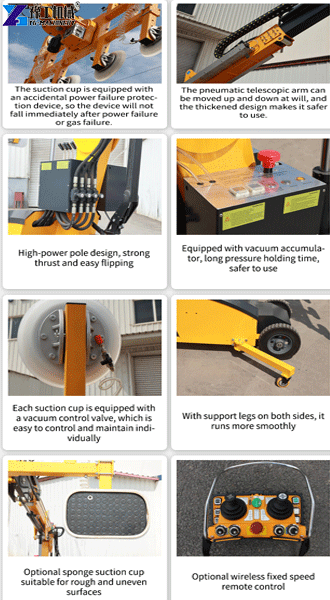

| Model Type | YG-LD-300 | YG-LD-400 | YG-LD-500 | YG-LD-600 | YG-LD-800 | |

| Load Capacity | 300kg(retract)150kg(extend) | 400kg(retract)200kg(extend) | 500kg(retract)250kg(extend) | 600kg(retract)300kg(extend) | 800kg(retract)400kg(extend) | |

| Lifting Height | 3500mm | 3500mm | 3700mm | 3700mm | 4500mm | |

| QTY of Suction Cap | 4pcs | 4pcs | 6pcs | 6pcs | 8pcs | |

| Rubber Suction Cap | 300mm | Ø300mm | Ø300mm | Ø300mm | Ø300mm | |

| Maintenance-free Battery | 2x12V/80AH | 2x12V/100AH | 2x12V/120AH | 2x12V/120AH | 2x12V/120AH | |

| Battery Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | |

| Drive motor | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | |

| Lifting Motor | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/12L | |

| Chassis L*W | 2660*810mm | 2660*810mm | 2800*810mm | 2800*810mm | 2800*810mm | |

| Driving Wheel | Ø250x80mm | Ø250x80mm | Ø300x100mm | Ø300x100mm | Ø300x125mm | |

| Packing Size(mm) | 2560*1030*1700 | 2560*1030*1700 | 2580*1050*1700 | 2580*1050*1700 | 3000*1250*2300 | |

| N.W/G.W | 1100/1150kg | 1280/1330kg | 1300/1350kg | 1400/1450kg | 1600/1650kg | |

| Loading Qty | 1x20GP/40GP: 6SETS/12SETS | |||||

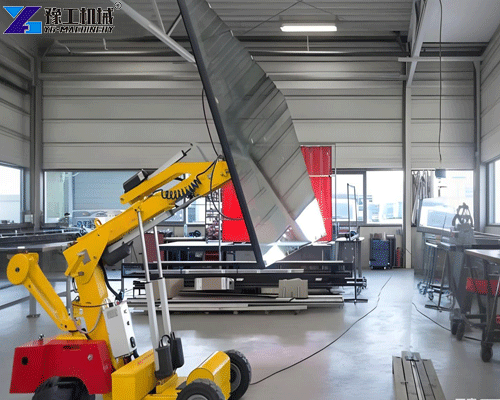

| Movement | Automatic(4 kinds) | 1. The suction cup frame flips 180° electrically. 2. The support plate automatically retracts. 3. Hydraulic arm lifts electrically. 4. The base of the whole machine moves 100-150mm horizontally. | ||||

| Manual (2kinds) | 1. The suction cup holder can be manually rotated 90 degrees (electrically powered optional). 2. The suction cup holder can be manually rotated 360 degrees (electrically powered optional). | |||||

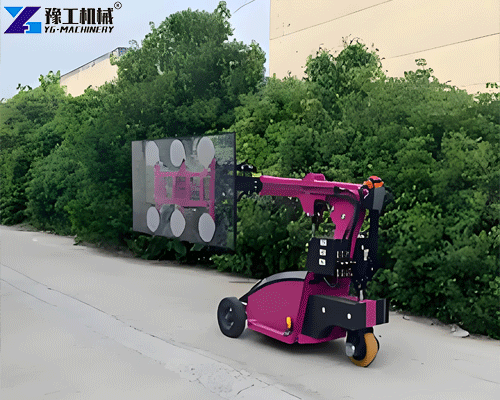

| Usages | Mainly used for the handling, movement, and installation of materials such as glass, marble, wood, iron plate, etc. | |||||

What Problem Does It Solve for Spanish Contractors?

Spanish glazing companies commonly face:

- High labor costs for manual glass installation

- Limited crane access in city-center projects

- Safety risks during large panel handling

- Inconsistent alignment during final placement

Traditional lifting methods slow down installation and increase dependency on skilled labor.

How the Glazing Robot Improves Installation Efficiency?

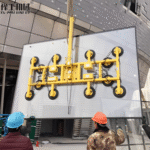

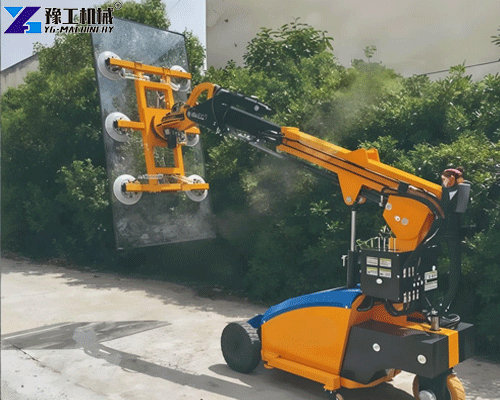

The machine enables controlled glass handling at ground level and façade edges.

Key functional benefits:

- Reduces manual handling steps by over 60%

- Improves panel alignment accuracy to ±2 mm

- Cuts average installation time per panel from 18 to 12 minutes

- Allows two operators instead of four

On-site performance is comparable to a compact glass robot used specifically for curtain wall applications.

Typical Application Scenarios of Glass Robot in Spain

- Commercial office curtain walls

- Hotel façade renovation projects

- Mixed-use buildings in urban centers

- Low- to mid-rise glass wall installation

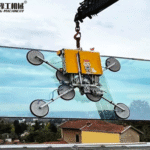

The system also performs effectively as a mobile glass robot vacuum lifter when cranes are restricted or inefficient.

Results from a Spain-Based Project

After deployment on a Madrid façade project:

- Daily installed panels increased by 36%

- Zero glass breakage incidents reported

- Labor cost per installed panel reduced by ~28%

- Equipment payback achieved within 14 months

The client confirmed the overall glazing robot price was competitive when compared with labor savings and project efficiency gains.

Why Contractors Choose This Glazing Robot for Sale?

Decision factors include:

- Stable vacuum performance for large glass panels

- High positioning accuracy for curtain wall systems

- Compact design for narrow sites

- Simple operator training and maintenance

The equipment is selected based on technical fit, not promotional claims.

FAQ about Glass Robot

Is this suitable for city-center projects?

Yes. Electric drive and compact dimensions allow operation in restricted areas.

Does it replace cranes entirely?

It handles most low- and mid-rise façade work independently. Cranes remain useful for upper floors.

What affects glazing robot price?

Load capacity, vacuum system redundancy, control functions, and certification requirements.

Delivery and support?

Standard lead time is 6–8 weeks. Remote technical support and spare parts service are available for Europe.

YG Machinery – Reliable Glass Robot Manufacturer with Export Experience

YG supplies glazing robots to Europe and other regions with a focus on engineering compatibility and real job-site performance. Each unit is configured according to glass size, site conditions, and safety standards.

If you are evaluating a glazing robot for sale for projects in Spain, this solution offers a practical balance between efficiency, safety, and cost control. Contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.