Installing large glass panels by glass installation equipment has always been one of the most challenging tasks on a construction site. Traditional glass installation relies heavily on manpower, cranes, and experience. A glass robot takes a different approach. By combining a vacuum glass lifter machine with flexible mobile equipment, it changes how glass is lifted, positioned, and installed on modern construction sites.

What Is a Glass Robot?

A glass robot is not a single fixed machine. In practical applications, it can be understood as:

Glass robot = glass lifter machine + mobile base

The glass lifter machine is a vacuum-based lifting unit responsible for gripping, rotating, tilting, and precisely positioning glass panels. The mobile base provides movement and reach, and can be a forklift, telehandler, crane, or spider crane depending on the job site.

This modular concept is what makes glass robots fundamentally different from traditional glass installation methods.

Traditional Glass Installation: Limitations and Risks

Traditional glass installation often relies on manual labor combined with basic lifting tools such as slings, hooks, or simple cranes. While still used in some projects, this approach has clear limitations:

- High labor intensity and safety risks

- Limited precision when positioning large glass panels

- Higher breakage rates, especially with oversized or tempered glass

- Inefficient for repetitive or high-volume installations

As glass panels become larger and buildings more complex, these limitations become more apparent.

Understanding Different Mobile Bases for Glass Robots

The real advantage of a glass robot lies in choosing the right mobile base, not the most expensive one.

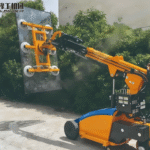

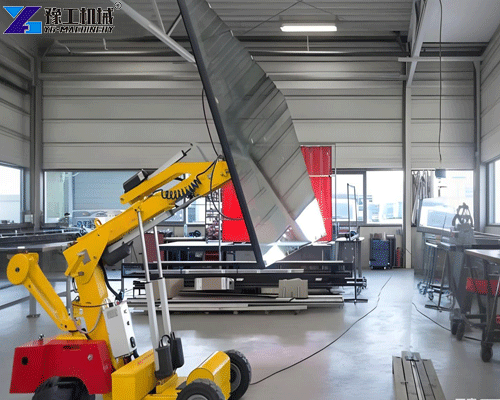

Forklift + Glass Lifter Machine

A forklift-mounted glass robot is ideal for:

- Warehouses and factories

- Low-rise buildings

- Short-distance horizontal transport

Advantages:

- Cost-effective

- Easy to operate

- Excellent for ground-level glass handling

Limitations:

- Limited vertical reach

- Not suitable for high-rise installation

Telehandler (Telescopic Forklift) + Glass Robot

A telehandler, also known as a telescopic boom forklift, significantly expands application scenarios.

Best for:

- Construction sites with moderate height requirements

- Curtain wall installation on low- to mid-rise buildings

- Projects requiring both reach and mobility

Why it works well:

- Telescopic boom extends forward and upward

- Maintains good stability

- Flexible alternative to cranes in many projects

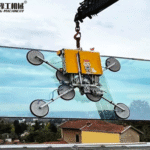

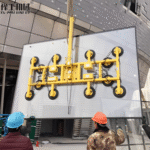

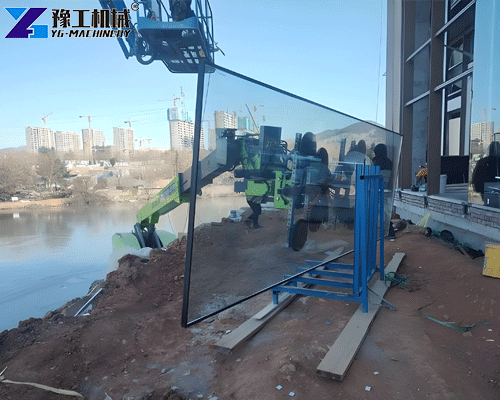

Crane + Glass Lifter Machine

When glass panels are extremely large or heavy, cranes remain essential.

Typical use cases:

- High-rise buildings

- Oversized architectural glass

- Long-distance vertical lifting

Key considerations:

- Requires more space and setup time

- Higher operational cost

- Best used when reach and load exceed telehandler limits

In this setup, the glass lifter machine provides precision, while the crane provides raw lifting power.

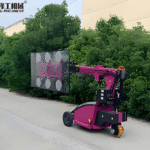

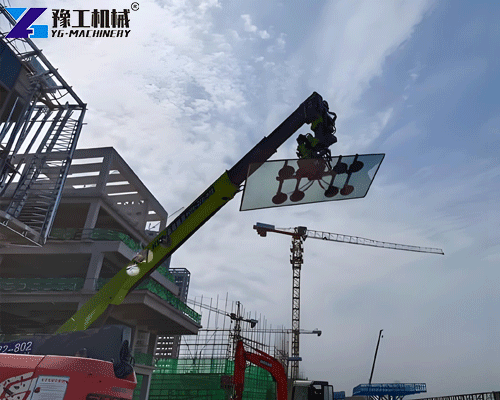

Spider Crane + Glass Robot

Spider cranes are increasingly popular for specialized environments.

Ideal for:

- Tight urban construction sites

- Indoor or rooftop installations

- Sites with low ground load capacity

Advantages:

- Compact footprint

- High precision control

- Easy transport and setup

For complex or restricted environments, this combination often delivers the best balance of safety and flexibility.

Matching Equipment Combinations to Project Types

The key is not buying the most advanced equipment, but choosing the most appropriate combination:

- Factories & warehouses: Forklift + glass lifter machine

- Commercial buildings: Telehandler + glass robot

- High-rise construction: Crane + glass lifter machine

- Confined or sensitive sites: Spider crane + glass robot

This approach allows contractors to control costs while maintaining safety and efficiency.

Why “Right Solution” Matters More Than “High Price”?

A common misconception is that higher-priced equipment automatically delivers better results. In reality, mismatched equipment often leads to:

- Lower efficiency

- Higher operating costs

- Unnecessary safety risks

A modular glass robot system allows users to adapt the same glass lifter machine to different mobile bases, reducing overall investment and improving return on equipment.

Final Thoughts

Compared with traditional glass installation methods, a glass robot offers a smarter and more adaptable approach. By combining a glass lifter machine with the right mobile base—forklift, telehandler, crane, or spider crane—contractors can tailor their solution to each project’s real needs.

The goal is simple: choose the right equipment combination, not the most expensive machine. Contact us to know more details now!【WhatsApp/WeChat/Phone】+86 13837115193.