Are you looking for a lower-cost way to explore mineral resources without sacrificing data quality? Do you need faster geological feedback to make drilling decisions with confidence? Or are you struggling with slow sample recovery and high operating costs in hard rock formations? If these questions sound familiar, an rc drilling machine may be exactly the solution you need.

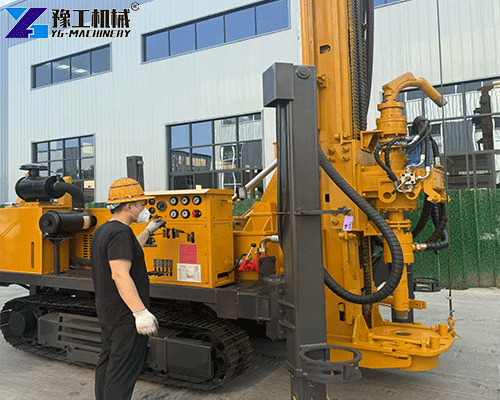

An RC drilling machine is designed to deliver clean, representative rock samples at high speed and low cost, making it one of the most efficient drilling solutions for mineral exploration, grade control, and geotechnical investigation.

What Is an RC Drilling Machine?

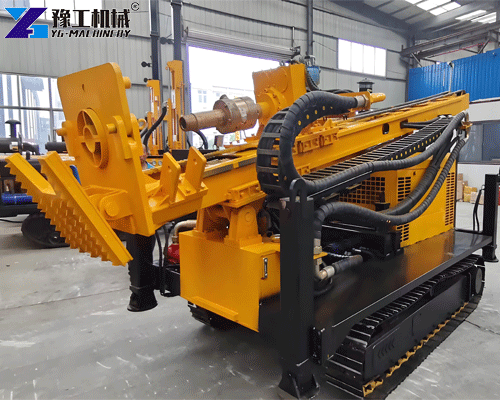

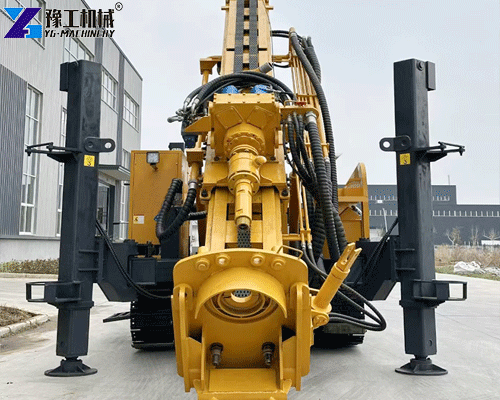

An rc drilling machine (also known as a reverse circulation drilling rig or reverse rotary drilling rig) uses compressed air to force rock cuttings up through the inner tube of a dual-wall drill pipe.

This reverse airflow system ensures samples are collected quickly, uncontaminated, and directly from the drill bit.

Unlike conventional rotary drilling, the reverse circulation drilling rig returns samples continuously and in real time—allowing geologists to analyze lithology and mineralization almost immediately.

RC Drilling Machine Parameters

| Technical Parameters | Unit | YG-400 | YG-500 | YG-600 | YG-800 | YG-1200 |

| Max drilling depth | m | 400 | 500 | 600 | 800 | 1200 |

| Hole diameter | mm | 105–305 | 105–400 | 105–450 | 105–550 | 105–800 |

| Recommended working pressure | MPa | 1.2–3.5 | 1.6–6 | 1.6–6 | 1.6–8 | 1.6–8 |

| Recommended air consumption | m³/min | 16–55 | 16–55 | 16–75 | 16–96 | 16–96 |

| Drill pipe length | m | 3 | 3 | 3 | 6 | 6 |

| Recommended drill pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| RC double-wall pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| Feed force | T | 6 | 7 | 7 | 11 | 13 |

| Lifting force | T | 22 | 25 | 29 | 47 | 57 |

| Fast lifting speed | m/min | 20 | 23 | 29 | 29 | 30 |

| Fast feeding speed | m/min | 32 | 33 | 33 | 42 | 44 |

| Max rotary torque | Nm | 8000/4000 | 10000/5000 | 12000/6000 | 18000/9000 | 24000/12000 |

| Max rotary speed | r/min | 75/150 | 75/150 | 75/150 | 70/140 | 86/172 |

| Aux winch lifting force | T | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 |

| Mast stroke | m | 1.6 | 1.6 | 1.7 | 1.7 | 1.7 |

| Travel speed | km/h | 10–35 | 10–35 | 10–35 | 10–35 | 10–35 |

| Gradeability | ° | 21 | 21 | 21 | 21 | 21 |

| Machine weight | T | 11 | 12 | 12.5 | 17 | 23 |

| Overall dimensions (L×W×H) | m | 7×1.85×2.86 | 7×2.1×2.9 | 7×2.1×2.9 | 10.5×2.25×3.3 | 11.5×2.25×3.4 |

| Engine | / | Yuchai 92kW | Cummins 132kW | Cummins 132kW | Cummins 194kW | Cummins 264kW |

Unique Advantages of RC Drilling Machines

- Faster Sample Recovery, Faster Decisions

RC drilling machines provide continuous sample output, allowing on-site geological logging without delay. This is critical for exploration projects where time directly affects project cost.

- Lower Cost Than Core Drilling

Compared with diamond core drilling, an rc drilling machine offers:

- Lower drilling cost per meter

- Faster penetration rates

- Reduced manpower requirements

This makes the rc drill rig price significantly more attractive for early-stage exploration and grade control programs.

- Cleaner, More Reliable Samples

Because cuttings travel inside a sealed inner tube, sample contamination is minimized. This improves data accuracy, especially in fractured or mixed formations.

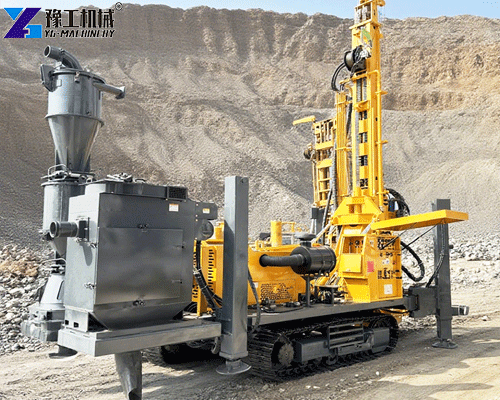

- Strong Adaptability to Harsh Environments

Modern reverse rotary drilling rigs are designed to operate efficiently in:

- Hard rock

- Dry and dusty regions

- Remote mining areas with limited infrastructure

Typical Applications of RC Drilling Machines

RC drilling technology is widely used in:

- Mineral exploration (gold, copper, iron ore, lithium)

- Grade control drilling in operating mines

- Geotechnical investigation

- Resource boundary definition

- Pre-feasibility studies

Many customers who need versatile core sampling also choose our hydraulic core drilling machines for projects requiring precise geological data, complementing the high-speed efficiency of RC drilling machines.

Who Needs RC Drilling Machines—and Where?

Ideal User Groups

- Mining companies

- Exploration contractors

- Geological survey teams

- Government mineral departments

High-Demand Regions

RC drilling machines are especially popular in:

- West Africa (Ghana, Mali, Burkina Faso)

- Central Africa (DRC, Zambia)

- Australia

- South America

- Middle East mining zones

In regions where drilling budgets are tightly controlled but decision speed is critical, reverse circulation drilling rigs offer the best balance between cost and performance.

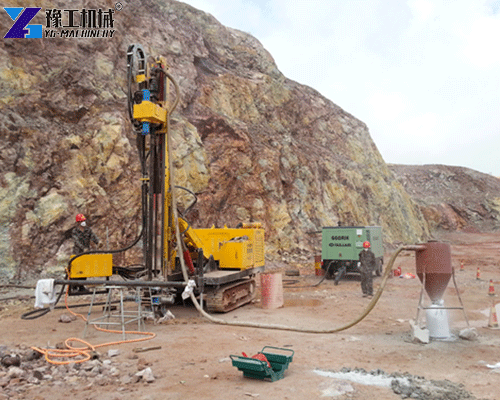

Ghana Customer Case: Reliable Performance in Gold Exploration

A mining contractor in Ghana purchased a YG rc drilling machine for a gold exploration project requiring fast sampling across multiple shallow to medium-depth holes.

Customer Feedback:

“The RC rig delivers samples consistently and clearly. We reduced drilling time significantly compared to our previous rotary setup, and the operating cost is well controlled.”

Key Results:

- Faster drilling progress

- Stable air pressure and sample return

- Reduced downtime thanks to standard spare parts

Following this project, several Ghana customers expanded their fleet with additional reverse circulation drilling rigs from YG.

How to Choose the Right RC Drilling Machine?

When evaluating an rc drilling machine, consider the following factors:

- Required Drilling Depth: Match compressor capacity and rig design to your target depth.

- Formation Conditions: Hard rock, fractured zones, or clay layers require different bit and air system configurations.

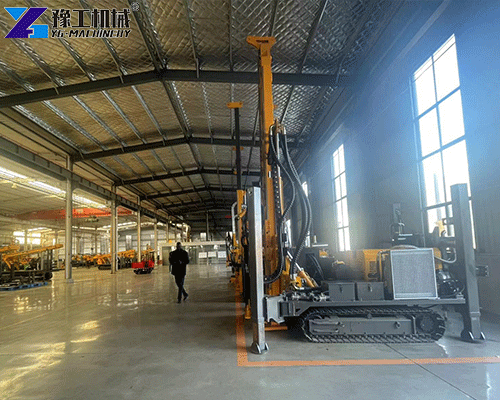

- Mobility Requirements: Remote sites may need truck-mounted or crawler-mounted RC rigs.

- Total Cost, Not Just RC Drill Rig Price: Look beyond the initial purchase price:

- Spare parts availability

- Ease of maintenance

- Technical support

A slightly higher-quality machine often delivers a much lower total cost of ownership.

Why Choose YG Machinery?

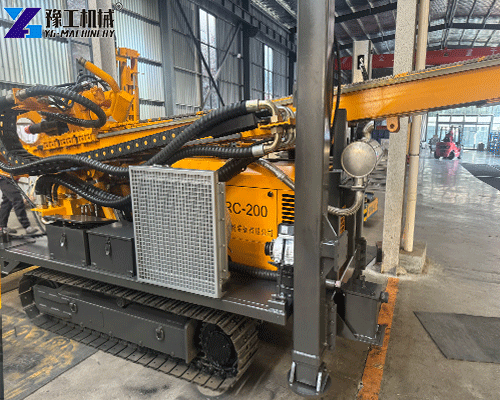

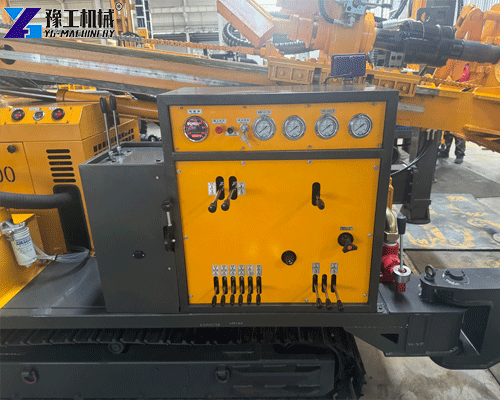

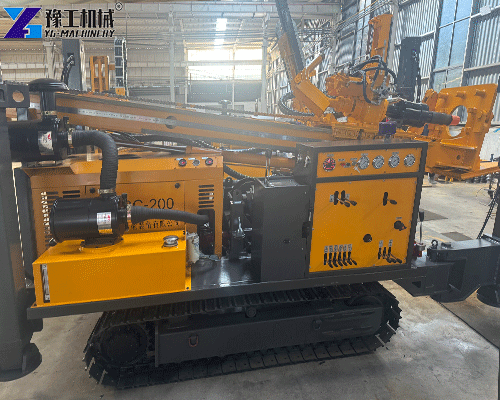

YG Machinery is a professional manufacturer of drilling equipment with extensive experience in international mining markets.

YG Advantages:

- Factory-direct pricing with no unnecessary intermediaries

- Stable quality control using standardized components

- Adequate spare parts supply, reducing long-term downtime

- Practical technical support based on real field conditions

YG RC drilling machines are engineered for durability, ease of maintenance, and adaptability to complex geological environments—making them a reliable choice for both contractors and mining companies.

RC Drill Rig for Sale in YG Machinery

If your goal is to reduce exploration costs, speed up geological decision-making, and maintain reliable sample quality, an rc drilling machine is one of the most practical investments you can make.

With proven performance in markets like Ghana and strong factory support from YG MACHINERY, a well-selected reverse circulation drilling rig can significantly improve project efficiency and profitability.