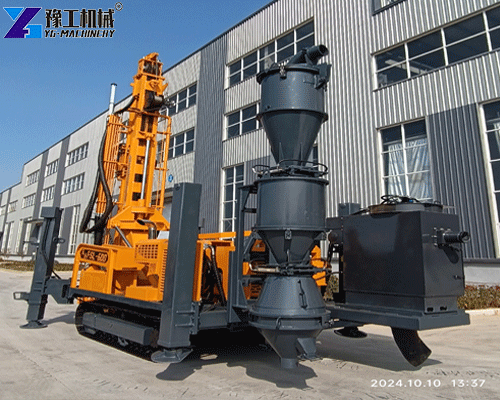

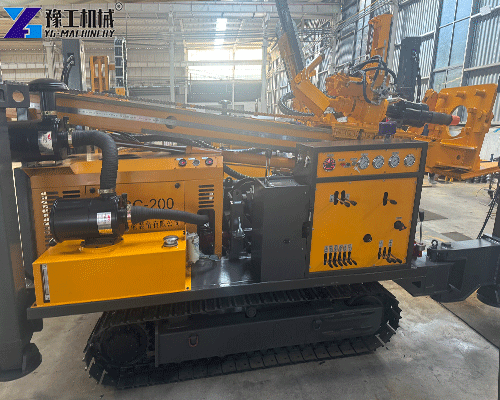

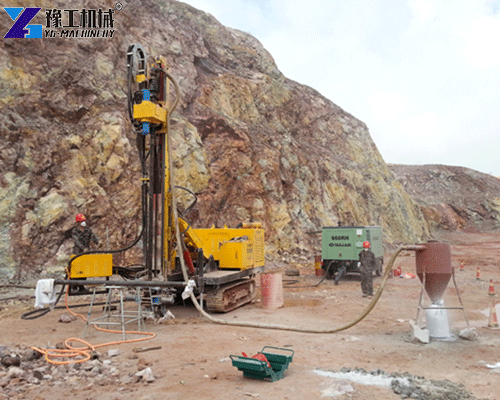

In March 2025, a leading mining company in Zimbabwe purchased a RC rig from YG Machinery to enhance their mineral exploration operations. The equipment, a high-performance reverse circulation drilling rig, addressed the challenges of deep core drilling in complex geological formations and received immediate positive feedback from the site engineers.

Zimbabwe Customer Challenges and Requirements

The mining company faced several issues prior to procurement:

- Traditional drilling rigs were slow, with limited penetration rates in hard rock areas.

- Frequent breakdowns and high maintenance costs delayed exploration schedules.

- Core recovery rates were inconsistent, affecting geological analysis accuracy.

To overcome these issues, the client required a robust, reliable, and cost-effective rc drilling equipment capable of maintaining high efficiency under harsh field conditions in Zimbabwe.

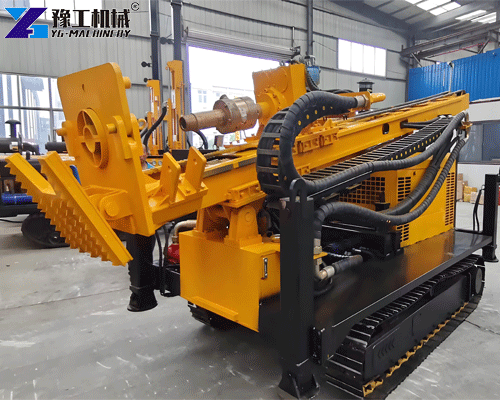

RC Rig Specifications and Features

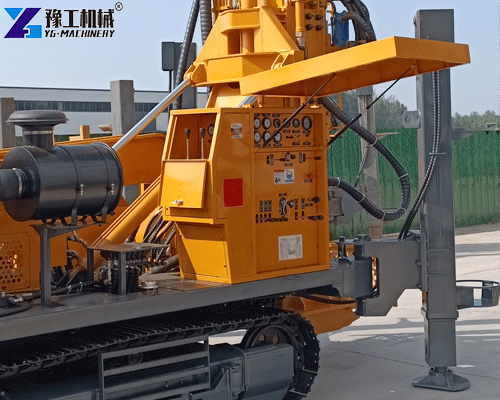

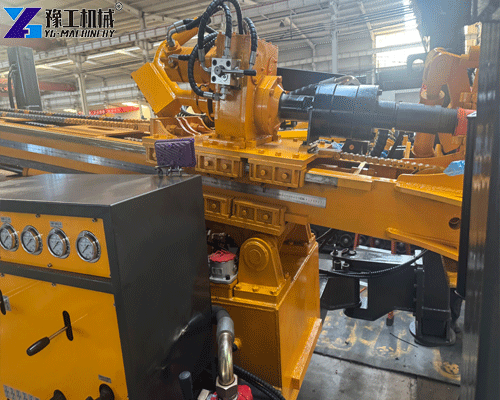

YG Machinery provided YG400 RC rig tailored to the client’s needs. Key specifications include:

| Technical Parameters | Unit | YG-400 | YG-500 | YG-600 | YG-800 | YG-1200 |

| Max drilling depth | m | 400 | 500 | 600 | 800 | 1200 |

| Hole diameter | mm | 105–305 | 105–400 | 105–450 | 105–550 | 105–800 |

| Recommended working pressure | MPa | 1.2–3.5 | 1.6–6 | 1.6–6 | 1.6–8 | 1.6–8 |

| Recommended air consumption | m³/min | 16–55 | 16–55 | 16–75 | 16–96 | 16–96 |

| Drill pipe length | m | 3 | 3 | 3 | 6 | 6 |

| Recommended drill pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| RC double-wall pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| Feed force | T | 6 | 7 | 7 | 11 | 13 |

| Lifting force | T | 22 | 25 | 29 | 47 | 57 |

| Fast lifting speed | m/min | 20 | 23 | 29 | 29 | 30 |

| Fast feeding speed | m/min | 32 | 33 | 33 | 42 | 44 |

| Max rotary torque | Nm | 8000/4000 | 10000/5000 | 12000/6000 | 18000/9000 | 24000/12000 |

| Max rotary speed | r/min | 75/150 | 75/150 | 75/150 | 70/140 | 86/172 |

| Aux winch lifting force | T | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 |

| Mast stroke | m | 1.6 | 1.6 | 1.7 | 1.7 | 1.7 |

| Travel speed | km/h | 10–35 | 10–35 | 10–35 | 10–35 | 10–35 |

| Gradeability | ° | 21 | 21 | 21 | 21 | 21 |

| Machine weight | T | 11 | 12 | 12.5 | 17 | 23 |

| Overall dimensions (L×W×H) | m | 7×1.85×2.86 | 7×2.1×2.9 | 7×2.1×2.9 | 10.5×2.25×3.3 | 11.5×2.25×3.4 |

| Engine | / | Yuchai 92kW | Cummins 132kW | Cummins 132kW | Cummins 194kW | Cummins 264kW |

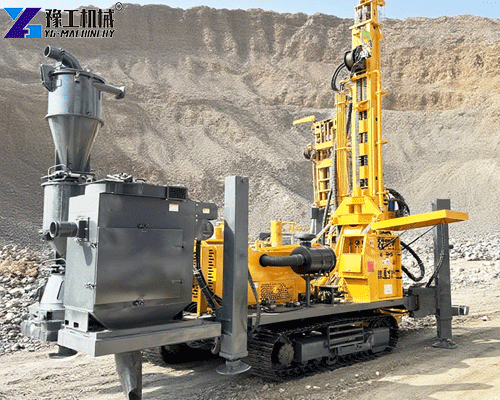

Additional features: modular design for easy transport, reinforced drill frame for stability, and compatibility with various core barrel standards (BQ, NQ, HQ). This configuration enabled the client to improve drilling speed by approximately 30% compared to previous rigs, while maintaining core recovery rates above 95%.

Why Choose RC Rig in Zimbabwe?

- Local conditions: Zimbabwe’s mining regions often feature hard rock, uneven terrain, and remote locations with limited road access.

- Investment value: Despite a higher initial cost compared to used machines, the rc drill rig for sale offered by YG Machinery ensures long-term cost efficiency due to reduced downtime, lower maintenance, and higher productivity.

- Operational reliability: The hydraulic system provides precise control over rotation and feed pressure, reducing drill bit wear and ensuring consistent core extraction.

Zimbabwe Customer Feedback

The Zimbabwe client shared their experience:

“The RC rig from YG Machinery significantly reduced drilling time. It is stable, easy to operate, and suitable for our deep core exploration tasks. The support team provided excellent guidance for setup and maintenance.”

The client also noted improved logistics support, timely delivery, and access to spare parts as key advantages over other suppliers.

Applications of RC Rig

The reverse circulation drilling rig is ideal for:

- Mineral exploration (copper, gold, cobalt)

- Geological survey and sampling

- Water well drilling in hard or consolidated formations

- Infrastructure projects requiring precise core data

In Zimbabwe, mining companies, geological survey firms, and engineering contractors benefit most from this equipment.

Choosing the Right Reverse Circulation Drilling Machine

When selecting an rc rig, clients should consider:

- Drilling depth and diameter requirements

- Geological conditions (hard rock vs soft soil)

- Mobility and logistics for remote sites

- Budget including long-term maintenance costs

- After-sales service and spare parts availability

YG Machinery offers a range of rc drill rigs for sale with customizable configurations to meet these criteria.

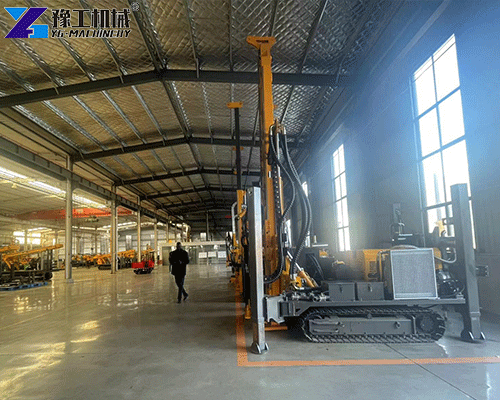

YG Machinery: Trusted Supplier for Zimbabwe and Beyond

YG Machinery has over 20 years of experience manufacturing drilling rigs, supplying reliable equipment such as rc drilling machine, core drilling machine for mining to countries like Zimbabwe, Ghana, Cameroon, and Burkina Faso. Advantages include:

- High-quality machines at competitive prices

- Complete spare parts inventory for global delivery

- Technical support and on-site guidance available

- Proven durability in harsh mining environments

Clients consistently report high satisfaction, making YG a trusted partner for mineral exploration and drilling projects.