Choosing the right solar pile driver is one of the most critical decisions in photovoltaic foundation construction. Different soil and geological conditions require different piling methods. Using the wrong solar pile driver can lead to low efficiency, higher costs, pile deviation, or even long-term foundation failure.

This guide explains all mainstream solar pile driver types used in modern PV projects, including screw, drilling, DTH, ramming, electric, and telescopic models—helping EPC contractors and solar developers choose the most suitable solution.

Why Solar Pile Driver Selection Matters in PV Projects?

In ground-mounted solar power plants, the pile foundation determines:

- Structural stability over 20–30 years

- Resistance to wind load and soil settlement

- Installation speed and labor cost

- Equipment investment and logistics efficiency

Key factors influencing solar pile driver selection include:

- Soil hardness and rock content

- Pile type (ground screw, H-beam, C-post, steel pipe)

- Construction schedule

- Power availability (diesel, hydraulic, electric)

- Terrain (flat land, slope, farmland, mountains)

Understanding different solar pile driver types allows contractors to avoid over-specification while ensuring reliable foundations.

Overview of Solar Pile Driver Types for PV Foundations

The most common photovoltaic pile driving machines can be classified into six categories based on their working method:

| Solar Pile Driver Type | Working Method | Suitable Ground | Air Compressor |

| Solar Screw Pile Driver | Rotary torque | Soil / clay / sand | ❌ |

| Rotary Drilling Type (Auger) | Hydraulic auger drilling | Mixed soil / gravel | ❌ |

| DTH Solar Pile Driver | Impact + compressed air | Hard rock | ✅ |

| Ramming Hydraulic Hammer | Hydraulic impact | Soil / compacted ground | ❌ |

| Electric Rotary Solar Pile Driver | Electric rotary torque | Soft to medium soil | ❌ |

| Telescopic / Skid-mounted Solar Pile Driver | Modular hydraulic system | Narrow or uneven sites | ❌ |

Each type addresses a specific construction challenge.

Rotary Drilling Solar Pile Driver (Auger Type)

The rotary drilling solar pile driver uses a hydraulic auger to pre-drill holes before inserting steel piles.

Key Advantages

- Precise depth and alignment control

- Effective in layered or mixed ground

- Reduces pile deviation

Suitable Soil Conditions

- Mixed soil with gravel

- Semi-hard ground

- Sites where direct screw piling is difficult

Typical Applications

- Large EPC projects

- PV sites with inconsistent soil layers

Rotary drilling is often chosen when higher accuracy is required but full rock breaking is unnecessary.

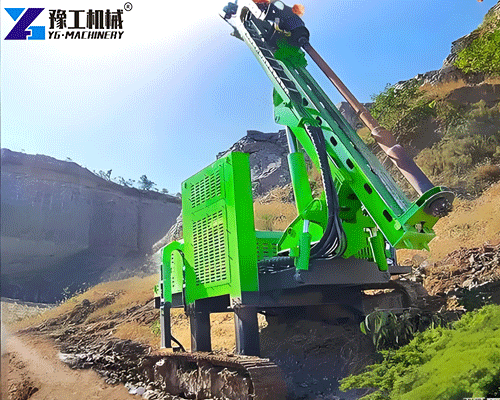

DTH Solar Pile Driver (Down-the-Hole Type)

A DTH solar pile driver combines impact force with compressed air to break hard rock formations.

Key Advantages

- Strong penetration capability

- Suitable for extreme geological conditions

- Stable drilling in high-strength rock

Suitable Soil Conditions

- Hard rock formations

- Mountainous or rocky solar sites

Typical Applications

- Rocky utility-scale solar plants

- High-altitude or uneven terrain projects

Although more complex and costly, DTH piling is often the only viable solution in rocky PV installations.

Ramming Hydraulic Hammer Solar Pile Driver

A ramming solar pile driver uses hydraulic impact energy to drive steel piles directly into the ground.

Key Advantages

- Simple structure

- High piling efficiency

- Suitable for standardized steel piles

Suitable Soil Conditions

- Soft soil

- Compacted soil

- Shallow foundation layers

Typical Applications

- Fast-track solar projects

- Flat land PV installations

Ramming types are ideal when speed matters more than precision drilling.

Telescopic / Skid-mounted Solar Pile Driver

This type features a compact, telescopic or skid-mounted structure, designed for narrow or complex sites.

Key Advantages

- High mobility

- Easy transportation

- Suitable for uneven terrain

Suitable Soil Conditions

- Variable soil

- Limited-access sites

Typical Applications

- Rooftop-adjacent solar installations

- Sloped or confined PV areas

These models improve flexibility without sacrificing performance.

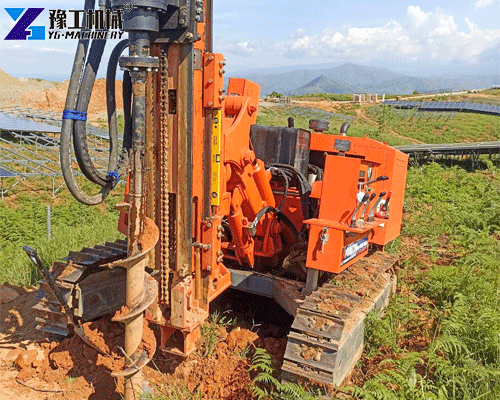

Solar Screw Pile Driver (Ground Screw Installation)

A solar screw pile driver uses hydraulic rotary torque to directly install ground screws or helical piles into the soil without pre-drilling.

Key Advantages

- Fast installation speed

- No vibration or impact

- No concrete foundation required

- Ground screws can be removed and reused

Suitable Soil Conditions

- Clay, sand, loam

- Medium-density soil

- Agricultural land and flat PV sites

Typical Applications

- Utility-scale PV projects

- Distributed solar farms

- Temporary or removable solar installations

This is one of the most widely used solar pile driver types due to its speed and simplicity.

Electric Rotary Solar Pile Driver

An electric rotary solar pile driver replaces diesel power with an electric drive system.

Key Advantages

- Zero emissions

- Low noise operation

- Lower operating cost

Suitable Soil Conditions

- Soft to medium-density soil

Typical Applications

- Urban or residential solar projects

- Noise-sensitive or emission-restricted zones

Electric models are increasingly popular in environmentally regulated regions.

How to Choose the Right Solar Pile Driver for Your Project ?

When selecting a solar pile driver, EPC contractors should evaluate:

- Ground conditions (soil vs rock)

- Pile type and diameter

- Project scale and timeline

- Power source availability

- Environmental restrictions

Typical EPC Selection Logic

- Soft soil → Solar screw pile driver

- Mixed ground → Rotary drilling type

- Hard rock → DTH solar pile driver

- Fast installation → Ramming hydraulic hammer

- Low noise / zero emission → Electric rotary solar pile driver

Large solar projects often use multiple piling methods across different zones.

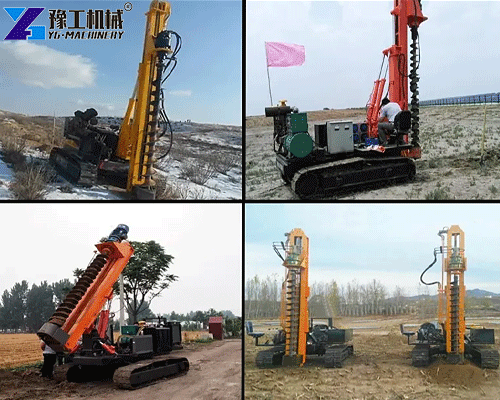

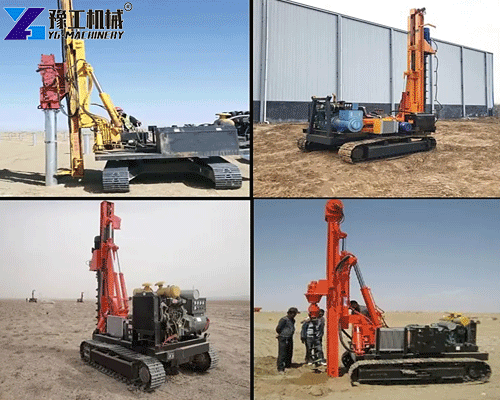

Solar Pile Driver Solutions from YG Machinery

YG Machinery offers a full photovoltaic pile driving equipment lineup, including:

- Solar screw pile drivers

- Rotary drilling solar pile drivers

- DTH rock drilling solutions

- Ramming hydraulic hammer pile drivers

- Electric rotary solar pile drivers

- Telescopic and skid-mounted PV piling machines

Each model is engineered to adapt to different geological conditions and project scales, helping EPC contractors achieve safe, efficient, and cost-effective installations.

Conclusion

Understanding all solar pile driver types is essential for building reliable PV foundations. By matching the piling method to actual ground conditions and project requirements, solar developers can significantly reduce installation risks, control costs, and improve long-term performance.

For professional solar pile driver selection and customized solutions, working with experienced equipment manufacturers makes all the difference.