YG Machinery (Zhengzhou Yugong Machinery) has been deeply engaged in the steel machinery industry for many years and dedicates itself to providing high-precision, efficient, reliable, and durable rebar processing equipment that helps construction and infrastructure projects progress smoothly worldwide.

YG’s Main Rebar Machinery Products (Steel Machinery Series)

The following rebar machines are considered industry stars in the YG product portfolio:

- Rebar Straightening and Cutting Machine: This machine straightens bent or coiled rebar and cuts it to size, accommodating a wide range of diameters (e.g., 4–14 mm) and delivering high-precision cutting. Highly automated, it boasts a pulling speed of up to 50 m/min and a cutting tolerance of only ±0.5–1 cm. The machine is easy to operate, stable, and durable.

- CNC Stirrup Bending Machine / Rebar Bender: This CNC stirrup bending machine is suitable for processing a variety of rebar shapes, including window-shaped and hook-shaped stirrups, with high precision and efficiency. Precisely controlling the bending angle and shape allows it to accommodate a variety of stirrup designs, making it widely applicable on-site and in fabrication plants.

- Threaded Rebar Coupler / Thread Rolling Machine: Through threaded connectors or thread rolling technology, these machines achieve seamless rebar connections, reducing welding and tying workload. Suitable for high-strength structures and prestressed engineering, they are the preferred equipment for many modern construction projects.

- Punch and Shear Machine: Multi-functional rebar processing equipment, combining punching and shearing functions, meets a variety of rebar cutting and punching needs. Engineers and builders commonly use it in steel structure and prefabricated component processing, improving on-site flexibility and efficiency.

Common Applications — Scope of Steel Machinery Use

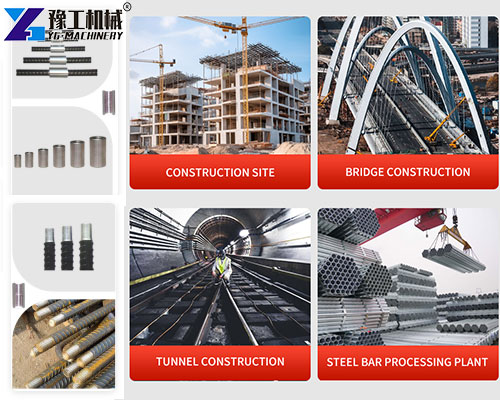

This series of rebar machinery is widely used in:

- Construction sites and infrastructure construction: Rebar processing and installation for projects such as buildings, bridges, tunnels, and underground structures.

- Prefabricated component plants and rebar processing plants: Mass production of rebar components uses straight cutting, hoop bending, and thread rolling equipment to improve efficiency and quality

- Highway, railway, and large-scale infrastructure construction: Ensures accurate rebar processing, controlled construction schedules, and compliance with safety standards.

FAQ about Steel Machinery

Q1: How do I choose the right rebar straight cutting machine model?

Please consider your rebar diameter range, production requirements, and cutting accuracy before selecting the appropriate model.

Q2: What bending shapes does the CNC stirrup bending machine support?

YG’s CNC stirrup bending machine is programmable and supports a wide range of stirrup shapes, flexibly adapting to project design requirements.

Q3: What applications are threaded couplers suitable for?

They are suitable for high-strength structural connections and prestressed concrete projects, improving installation efficiency and structural quality.

Q4: What rebar thickness can the Punch & Shear machine handle?

Please refer to the specific product specifications. If you need to handle thicker rebar, we can provide customized services to meet your needs.

Q5: What after-sales service does YG’s rebar machinery offer?

We provide equipment installation guidance, operator training, remote or on-site technical support, and sufficient spare parts to minimize downtime.

Steel Machinery Display

CNC Stirrup Bending Machine

Rebar Forging Machine

Rebar Thread Cutting Machine

Threaded Rebar Coupler

Rebar Straightening and Cutting Machine

Punch and Shear