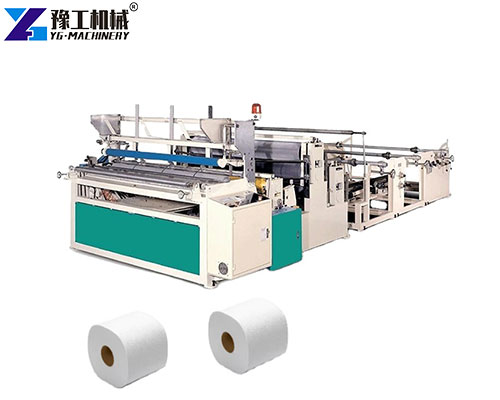

A paper roll making machine is an ideal investment for entrepreneurs looking to start or expand their paper product business. Compact, cost-effective, and easy to operate, this equipment transforms raw paper rolls into finished tissue or toilet paper products. It’s widely used in household paper production, small-scale paper processing plants, and rural or developing areas with growing demand.

These machines are highly versatile, offering significant advantages such as low investment cost, quick returns, minimal labor requirement, and high efficiency. Whether you aim to manufacture household tissues or commercial toilet paper, a reliable machine ensures consistent product quality.

Paper Roll Making Machine Parameters

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Working Principle of the Machine

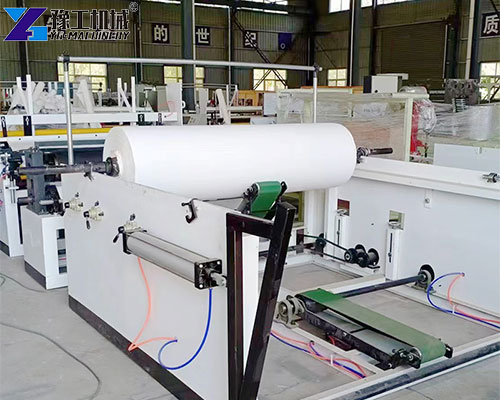

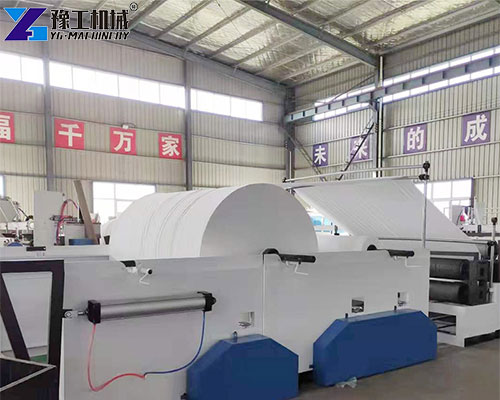

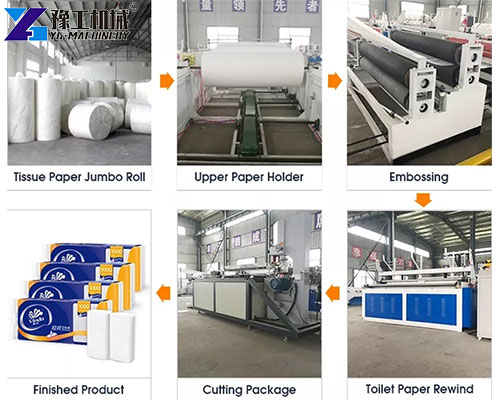

The working process starts by unwinding raw jumbo rolls onto the feeding stand. The paper passes through embossing and perforation rollers, which improve texture and ease of tearing. Then, it is rewound into small toilet paper rolls. In a fully automatic toilet paper making machine, cutting and packaging are also seamlessly integrated.

The rewinding process is controlled by programmable logic controllers (PLCs) to maintain precision. Some machines use pneumatic systems for unwinding, ensuring smoother operation. The finished rolls can then be sent to the packaging unit for final processing.

Key Advantages of the Small Tissue Paper Making Machine

- Low Investment, High Return: Designed for small businesses and startups, this machine offers a cost-effective solution with a quick return on investment, making it ideal for new entrants to the tissue production market.

- Compact & Space-Saving Design: Its small footprint allows installation in tight workshop spaces without compromising on production capacity—perfect for businesses with limited operational areas.

- Efficient & Labor-Saving: Automated operation ensures stable output with minimal manual intervention. High-speed rollers and advanced components boost production efficiency and reduce operational costs.

- Flexible & User-Friendly: Equipped with a PLC touch screen, it’s easy to operate. The machine supports customization options such as embossing patterns, perforation, and varying roll lengths and diameters.

This machine simplifies tissue paper manufacturing while optimizing performance and reducing overall production costs.

Application of Fully Automatic Toilet Paper Making Machine

- Local Tissue Brands: Ideal for brands seeking to control quality, cost, and branding by shifting from outsourcing to in-house toilet paper production.

- Small to Medium-Scale Factories: Perfect for manufacturers aiming to produce toilet rolls, kitchen rolls, or napkins efficiently, while maintaining scalability for future expansion.

- Rural Industrial Projects: A cost-effective solution for rural entrepreneurs or cooperatives looking to start a low-risk, high-demand hygiene product business with minimal labor needs.

With the rising demand for hygiene products, these machines are gaining popularity as essential equipment in the paper goods manufacturing industry.

How Much Is the Small Toilet Paper Machine Price?

The small toilet paper machine price varies depending on features, automation level, and output capacity. Generally, the price is lower than that of large-scale equipment, making it suitable for startups. YG Machinery offers models with flexible configurations to meet various customer budgets.

If you’re planning to upgrade to a small tissue paper making machine or explore more automation, we also provide advanced solutions. Our engineers will guide you to choose the best fit for your needs.

Contact YG Machinery – Your Trusted Manufacturer

YG Machinery is a professional manufacturer of paper processing equipment with years of experience in design, production, and sales. We provide high-performance paper roll making machines with complete after-sales support including installation, training, and maintenance.

In addition to paper machines, we also supply: wet wipe machines, paper cup machines, tissue paper making machine, etc. Contact us now.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.