In January 2025, Paul, a contractor from Texas specializing in industrial flooring and waterproofing services, contacted YG Machinery with a specific concern. He had recently accepted several large-scale waterproofing contracts involving underground parking lots and chemical containment tanks. However, his current equipment was outdated, with low spray efficiency and frequent maintenance issues. After researching various options and comparing suppliers, Paul chose YG’s high-performance polyurea spray machine. His decision was largely driven by the competitive polyurea spray machine price and the technical support YG promised during installation and training.

This successful cooperation not only solved Paul’s project pain points but also provided insight into the rising demand for reliable polyurea equipment in the United States, particularly among mid-sized construction and industrial coating contractors. More and more U.S. businesses are looking for fast-curing, highly durable coating solutions, and this trend directly drives the market interest in YG’s machines.

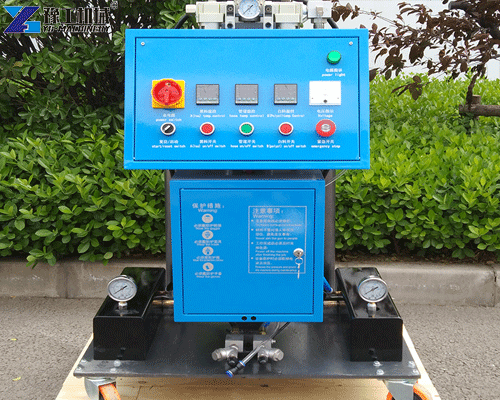

Key Technical Parameters of YG Polyurea Spray Machine

| Model | YG-25 | YG-30 | YG-28 | YG-36 |

| Power | three-phase 380V 50Hz | three-phase380V 50Hz | three-phase 380V 50Hz | three-phase 380V 50Hz |

| Heating power | 9.5KW | 18KW | 15KW | 22KW |

| Driven mode | pneumatic | pneumatic | pneumatic | hydraulic |

| Air source | 0.5~0.8MPa≥ 0.9m3/minute | 0.5~0.8MPa≥ 1.2m3/minute | 0.5~1 MPa≥ 1m3/minute | 0.5~0.8MPa≥ 0.5m3/minute |

| Material output | 2-10kg/minute | 2-10kg/minute | 2-10kg/minute | 2-12kg/minute |

| Max pressure | 25Mpa | 30Mpa | 28Mpa | 36Mpa |

| AB ratio | 1:1 | 1:1 | 1:1 | 1:1 |

The machine is designed with robust safety features, dual temperature control systems, and energy-saving circuits. It’s well-suited for various commercial and industrial applications, including roof waterproofing, pipeline protection, flooring, and truck bed linings.

Rising Demand in the U.S. and Common Customer Issues

The U.S. polyurea coating market has been expanding rapidly due to infrastructure upgrades, oil and gas industry maintenance needs, and stricter regulations for corrosion resistance. However, many buyers, like Paul, face similar challenges:

- Overpriced machines with limited features.

- Lack of post-sale support.

- Unstable spray patterns leading to coating failure.

- Incompatible equipment for various polyurea formulations.

This is where a cost-effective and versatile solution makes a difference. YG Machinery has noticed that polyurea spray machine price is not just about the initial purchase cost — it’s about what users receive in return in terms of performance, lifespan, and after-sales service.

A Practical Solution: Why Paul Chose YG Polyurea Equipment?

Paul’s old machine often stalled under high workloads and couldn’t maintain a consistent heating temperature, leading to substandard coatings and time delays. After discussing his project needs with YG’s technical team, he chose the YG-P2000 Pro model.

The machine’s dual heating zones helped stabilize polyurea flow, reducing material waste and improving coating quality. Within two months of using it, Paul reported a 30% increase in application speed and fewer touch-ups. He also appreciated that it was compatible with his preferred material brand, Rhino Linings.

Thanks to this upgrade, Paul completed his largest containment project on time, won repeat contracts, and left this feedback:

“The polyurea sprayer I bought from YG has been a game changer. It’s faster, more precise, and the price was unbeatable for this level of performance. I was also surprised by how simple it was to train my team.”

Benefits and Applications of Polyurea Sprayer

This high-performance sprayer is engineered to meet the growing demands of industrial coating jobs across the U.S. Its consistent output and temperature control deliver smooth, seamless finishes with minimal overspray. The coating adheres well to concrete, metal, and wood, making it highly flexible across projects.

Key applications include:

- Roof waterproofing.

- Pipeline and tank protection.

- Bridge deck coating.

- Vehicle bed liners and trailers.

- Industrial flooring and chemical storage facilities.

These versatile use cases also appeal to rental service providers, who require rugged and multi-purpose polyurea machines to meet a range of customer needs.

Polyurea Spray Machine Price in YG Machinery

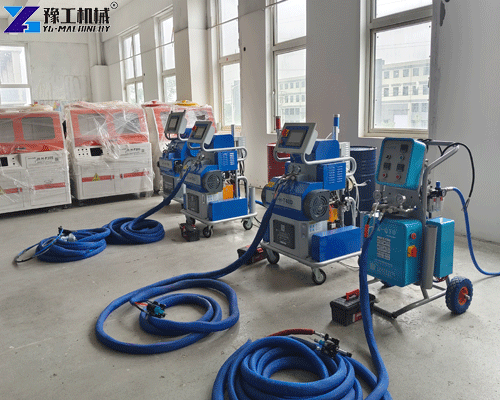

YG Machinery isn’t just a seller — it’s a committed manufacturer. From initial inquiry to delivery, YG offers full support, including competitive price, virtual training, operation manuals, and long-term spare part supply. The company also customizes machines based on specific project requirements.

With transparent pricing, dependable machinery, and strong after-sales support, YG has become a trusted name for polyurea machine for sale inquiries, particularly among U.S. contractors and applicators. In addition, YG offers: polyurethane foam spray machines ideal for roof insulation, tank waterproofing, and other building protection projects, etc. For reliable performance, competitive polyurea coating machine price, and consistent customer support, contact YG Machinery now.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.