At a time when the demand for disposable paper cups is growing rapidly, paper tea cup making machine (paper tea cup molding machine) is becoming the ideal paper cup production equipment for the catering, tea and beverage store and take-away service industries due to its high degree of automation, easy operation, and wide range of application. The machine can make all kinds of paper cups, including tea cups, coffee cups, cold drink cups, disposable water cups, etc., to meet the needs of different scenarios, and has become a low-cost, high-return option for many entrepreneurs.

Paper Tea Cup Machine Parameters

| Model | YG-DP10 | YG-DP16 | YG-GS120 |

| Production Speed (pcs/min) | 80-110 | 70-90 | 100-120 |

| Voltage | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase | 380V/50Hz, Three Phase |

| Paper Cup Specifications (oz) | 3oz-12oz | 3oz-16oz | 3oz-16oz |

| Machine Package Size (L*W*H, mm) | 2150x1100x1750 | 2150x1100x1950 | 2180x1050x1600 |

| Paper Stock / Material Requirements | 160-350g Single & Double PE Coated Paper | 160-350g Single PE Coated Paper | Single & Double Coated Paper |

| Power (KW) | 7.8KW | 5.5KW | 7KW |

| Weight (Kg) | 1700Kg | 1600Kg | 2100Kg |

| Appropriate customer groups | Start-ups or individuals | Small and medium-sized factories | Big factory |

| Paper Thickness Requirements (g/㎡) | 150-350g/㎡; ±20g/㎡ | ||

| Gas Supply Requirements | 0.6-0.8Mpa; 0.4m³/min | ||

| Cup Body Sticking Method | Ultrasonic Heating | ||

| Bottom Heating Method | Nest Bottom Heating (5 groups) | ||

| Molds Customization | Customizable According to Customer Requirements | ||

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-120pcs/min. | |||

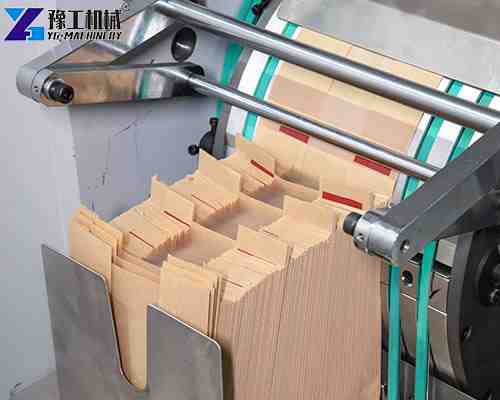

Replacement of molds is simple and convenient, users only need to adjust the molds to easily produce paper tea cups of different capacities without complicated operation, suitable for first-time entrepreneurs.

Paper Tea Cup Making Machine Features and Advantages

- Not only support tea cups, but also can produce coffee cups, cold drink cups, etc., greatly enhance the utilization rate of the equipment.

- PLC intelligent control system, human-machine interface design, reduce the operating difficulty, even non-technical personnel can quickly master.

- The equipment runs stably, with a number of safety protection functions such as fault alarm, molding detection, etc., to guarantee the safety of the operator.

- “Paper cup machine + air compressor + raw material paper” complete set of programs, easy to put into production, only one person to operate, small footprint, low energy consumption, short-term profit can be realized back to the capital.

Operation and Safety Tips

Please check whether the mold installation is in place before the equipment is turned on, and make sure the air pressure is between 0.4-0.6Mpa. Keep the equipment clean during the production process and change the lubricating oil regularly to prolong the service life. Mould replacement should be operated without power to ensure the safety of personnel.

Customer Cases

Customers from UAE, Kosovo, Kenya and other countries have purchased the whole set of “Paper Cup Machine + Air Compressor + Raw Material Paper” through YG Machinery, and realized a smooth transition from zero base to rapid production.

- A customer in the United Arab Emirates, who opened a new environmental protection paper cup factory in Dubai, used the paper tea cup making machine provided by YG to produce double PE laminated paper cups for hot drinks, and completed the cost recovery in only 3 months, and successfully signed a contract for supplying the local chain of coffee shops;

- In Kosovo, a start-up entrepreneur started production in the local market with the help of our complete set of equipment, specializing in the production of small and medium volume paper cups, and the production of paper cups is now underway. In Kosovo, an entrepreneur started production with our full set of equipment in the local market, focusing on the production of small and medium capacity paper tea cups and cold drink cups, with stable product quality and beautiful appearance, and successfully entered into a number of supermarkets and restaurant chains;

- In Kenya, the customer customized different sizes of molds according to the local demand, and also do the production of paper plates and bowls, the products are hot sold in the schools, restaurants and street food stalls, and quickly open the market.

For new customers, YG Machinery not only provides equipment transportation, installation and commissioning services, but also arranges site visits to personally witness the actual production of customers who have already put into production, helping investors to reduce the risk of starting a business and increase confidence.

Why Choose YG Machinery as Your Paper Cup Machine Supplier?

As an experienced paper cup machine supplier, YG Machinery can not only provide paper tea cup making machine, but also customize the whole solution for customers, including raw material supply, customized molds and installation training. Our products have reasonable price, transparent and open cup making machine price, trusted by customers at home and abroad. We have exported to Southeast Asia, the Middle East and Africa for many times, with high repurchase rate and good customer satisfaction.

Meanwhile, we also recommend related products: fully automatic paper cup machine, paper bowl making machine, paper plate forming machine, paper cup printing machine, low price paper cup machine, etc. Contact us to start your journey of paper products production! [WhatsApp/WeChat/Skype/Telephone] +86 13837115193.