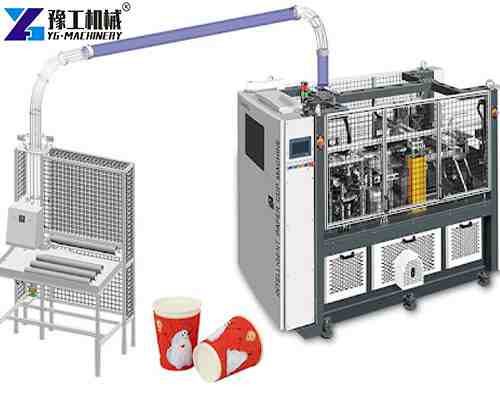

In the field of modern paper cup production, paper cup sleeve machine has become one of the indispensable equipment. This equipment is used to produce all kinds of paper cup sleeve, both can make single-layer cup sleeve, such as kraft paper, corrugated paper cup sleeve, also suitable for double-layer paper cup sleeve, widely used in the need for heat insulation, non-slip and aesthetic enhancement of the paper cup products. Whether in coffee shops, milk tea stores or packaging plants, paper cup sleeve forming machines are becoming more and more common.

YG Paper Cup Outer Sleeve Machine Parameters

| Model | YG-35 |

| Paper Cup Size | 3-16oz |

| Paper Cup Top Diameter | Min 65mm-max94mm |

| Paper Cup Bottom Diameter | Min45mm-60mm |

| Paper Cup Height | Min60mm-135mm |

| Raw Material | PE-COATED PAPER.RIPPLE PAPER ETC |

| Speed | 80-90pcs/min |

| Speed of 20 hours of stable running per day | |

| Suitable paper weight | 150-350gsm |

| Voltage supply | 220v50hz single phase/ 380v50hz 3-phase(better to use 380v50hz 3-phase)*If the user’s voltage supply is different, please inform us in advance. |

| General power | 4.7KW |

| Net weight | 1500kgs |

| Measurement (mm) | 2150*950*1650MM |

| Cup Side Sealing | Ultrasonic |

| We can customize the machine and mold according to the customer’s requirements. | |

This machine especially emphasizes on the safe operation: it is equipped with emergency stop button, overload automatic shutdown function, and reminds the user to choose the appropriate voltage according to the power supply configuration, in order to ensure that the equipment runs stably for a long time.

Working Principle

Paper cup sleeve machine completes the production of cup sleeve through five steps of automatic feeding, preheating, curling, sealing and molding. The raw material is fed into the mold area through servo control, and after heating and softening, it is sealed and shaped by ultrasonic wave to form precise and strong cup sleeve. This process does not require complex manual operation, it automatically completes the edging and gluing of the paper cup sleeve, and the finished cup sleeve is beautiful and uniform, suitable for all kinds of double-layer hot beverage cups.

Paper Cup Sleeve Forming Machine Features

- High efficiency, low energy consumption, high degree of intelligence.

- Different from the traditional equipment, YG equipment adopts double servo drive system, which ensures the tension control and cutting precision of the cup sleeve and avoids the problem of “crooked sleeve”.

Application Scenario

- The equipment has a wide range of applications and can produce paper cup sleeves of various sizes and shapes to meet the market demand for coffee, milk tea, cold drinks, etc.

- Especially in the high-end customized market, double wall paper cup sleeve machine is being adopted by more and more beverage brands to enhance brand image and user experience. At the same time, it has an important value in hot drink insulation, feel improvement, brand promotion, etc., so the market demand continues to grow.

YG Machinery-A Trusted supplier of Paper Products Machinery

As a professional manufacturer, YG Machinery has long been committed to providing customized and high-performance paper cup equipment solutions for global customers. We support non-standard customization of equipment and molds to ensure that we can meet the diversified needs of customers in different regions. Our machine not only enhances the functionality and aesthetics of paper cup products, but also is a reliable choice to improve production efficiency and reduce labor costs. We also produce the following products: paper cup forming machine, double wall paper cup machine, paper cup paper cutting machine, paper bowl forming machine, automatic paper plate machine,etc. Welcome to contact us for exclusive equipment quotation and technical support to make your paper cup production more efficient and professional! 【WhatsApp/WeChat/Phone/Skype】+86 13837115193.