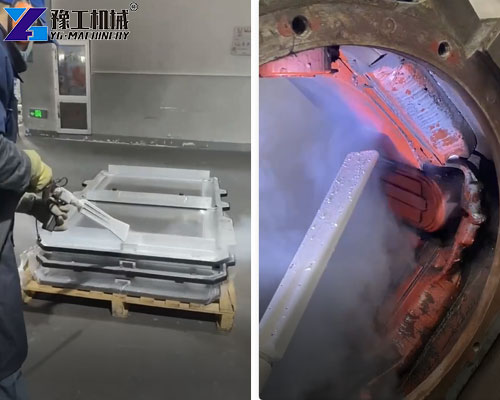

A few months ago, several sets of YG dry ice blasting machines were successfully delivered to a leading manufacturing facility in Lyon, France. The machines were promptly put to work in automotive mold cleaning and factory equipment maintenance. Since then, the client has shared highly positive feedback, praising the efficiency, eco-friendliness, and non-abrasive performance of the technology. This case also provides valuable insights into the dry ice cleaning machine cost and its return on investment for European industrial users.

Cost Analysis: Is the Dry Ice Cleaning Machine Cost Justified?

The client conducted a full ROI analysis comparing traditional cleaning methods and the new dry ice cleaning system. Here’s a simplified summary of their findings:

| Parameter | Traditional Cleaning | Dry Ice Cleaning |

| Initial Equipment Cost | Low | Higher |

| Cleaning Time | 90 mins avg | 45 mins avg |

| Water/Chemical Usage | High | None |

| Downtime (Monthly) | 8 hours | 3 hours |

| Labor Requirement | 2+ workers | 1 operator |

| Equipment Wear & Tear | Moderate | Minimal |

| Total Monthly Cost | €1,600+ | €900–€1,100 |

These numbers demonstrated that although the machine cost was a larger upfront investment, the monthly operational savings were substantial. With an estimated payback period of under six months, the client is now a strong advocate of the technology.

Why French Companies Are Rethinking Cleaning Strategies?

In recent years, companies across France have faced increasing pressure to adopt environmentally responsible cleaning processes. From food manufacturing to automotive production, factory managers are under the microscope to reduce water use, avoid harsh chemicals, and meet EU-level hygiene and safety standards. Traditional pressure washers and chemical solvents no longer meet these needs.

The client in Lyon originally relied on manual scrubbing and chemical solutions for cleaning molds and conveyor belts. However, these methods were labor-intensive, time-consuming, and created a lot of waste. Production downtime was also a major issue.

After exploring alternatives, they approached YG Machinery for a dry ice cleaning system that would be fast, efficient, and compliant with sustainability goals. A key consideration was the dry ice cleaning machine cost compared to other cleaning technologies—and whether the investment would reduce long-term maintenance and labor expenses.

What Makes Dry Ice Washer Worth the Cost?

While the cost may seem high at first glance, French customers like our Lyon-based client quickly realize that it pays for itself through:

- Reduced labor costs: One technician can operate the machine with minimal training.

- Minimal downtime: No drying time or disassembly needed.

- Eco-friendly operation: No chemicals, water, or secondary waste.

- Versatility: Applicable for electronics, mechanical parts, car interiors, food processing, and more.

In this case, the client chose two models—one portable and one high-capacity version—for different cleaning zones in the facility. One machine was designated for routine maintenance in confined areas, while the larger unit handled cleaning on production lines and heavy machinery.

Even in the first month of operation, the machines had reduced cleaning time by over 40%, and maintenance staff reported fewer mechanical failures due to residue buildup. Their operations team said that switching to a dry ice washer saved not only time but also avoided costly repairs from abrasive cleaning.

Application Example: Dry Ice Washer for Automotive Interiors

One of the standout features appreciated by the client was the ability to use the dry ice cleaning machine for cars, particularly for interior detailing. With no moisture and no chemicals involved, the machines could be used to clean upholstery, dashboards, air vents, and engine compartments—without any risk of water damage or chemical stains.

For their side business in automotive refurbishment, this opened new revenue channels. They could now offer premium dry ice interior cleaning services for high-end vehicles—a growing trend across France. In this context, the dry ice cleaning machine cost was quickly recouped within weeks due to increased service offerings.

Challenges During Setup and YG’s Support

Of course, implementing new cleaning technology isn’t without its challenges. The client faced initial concerns about sourcing dry ice locally and optimizing air compressor settings for different cleaning tasks.Thankfully, the YG support team provided one-on-one remote training, startup guides in French, and personalized videos demonstrating use cases in real time.If you have any concerns, please consult YG anytime.

Dry Ice Cleaning System in YG Machinery

As a professional dry ice blasting machine manufacturer and supplier, YG Machinery is proud to serve industrial clients around the globe. We understand the unique needs of different sectors—from food processing and aerospace to automotive and electronics.

For our client in France, we didn’t just deliver a machine. We offered complete after-sales service, operational training, and ongoing consultation. Their success story is a testament to how innovative cleaning technology, when implemented correctly, can improve both productivity and sustainability.

If you’re a business in France—or anywhere in Europe—seeking reliable industrial cleaning solutions, YG is here to help. Whether you’re concerned about compliance, performance, or cost efficiency, we can provide a dry ice cleaning system that meets your specific needs.

In addition, we also have portable sandblasting machines, automatic sandblasting machines, sandblasting rooms, hanger type shot blasting machines, pass-through shot-blasting machines, GRC machines, mortar sprayers, shotcrete sprays, hydroseeding machines, etc.

Interested in upgrading your cleaning technology? Contact YG Machinery today to get a free quote or learn more about our product line.

[whatsapp/wechat/phone/Skype]+86 13837115193.