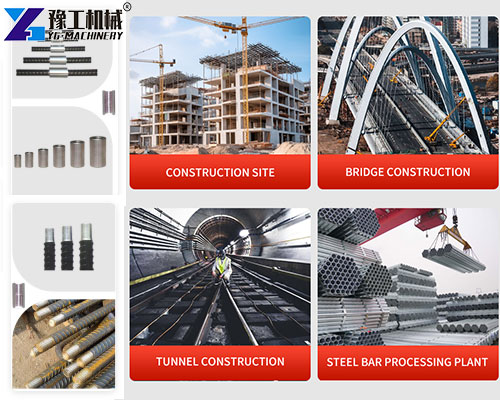

A rebar thread cutting machine is a powerful tool used in construction to form precise, high-strength threads on the ends of rebars. This machine combines rib-stripping and rolling to prepare rebars for connection using mechanical couplers, significantly improving joint strength. It has become an essential piece of equipment on modern job sites, offering quick processing, reliable performance, and compatibility with various steel bar sizes. Whether for bridges, buildings, or tunnels, it helps save time and ensures safety in reinforcement work.

Rebar Thread Cutting Machine Parameters

| Model | YGS-40 | YGT-40 | YGA-40 |

| Processing diameter range | 16-40mm | ||

| Thread rolling length | 0-80mm | 0-80mm | 0-100mm |

| Power voltage | 4kw/380v 50hz | 4kw/380v 50hz | 7.5kw/380v 50hz |

| Working efficiency | 15s/forming | 8s/forming | One-touch auto forming |

| Machine weight | 320kg | 350kg | 400kg |

| Machine size | 115*50*106cm | 110*60*130cm | 126*70*106cm |

| Type | Standard type | Upgrade type | Full automatic type |

How the Rebar Thread Cutting Machine Works?

The machine operates through a sequence of rib stripping and thread rolling. Once the rebar is clamped into position, the cutting blade strips the ribs from the steel bar. The roller head then forms threads by cold-rolling, which hardens the metal and produces a uniform thread that matches the strength of the base material. A built-in cooling system ensures long tool life and prevents overheating during continuous operation.

Advantages of Rebar Threading Machine

- One of the biggest advantages is its high processing efficiency. With one-time clamping, the entire thread forming process can be completed automatically.

- The threaded ends are strong and precise, and the machine supports both left-hand and right-hand threading.

- The rolling dies are durable and cost-effective, making them ideal for large-volume projects.

- Additionally, the automated features reduce operator fatigue and improve consistency in output.

Applications of Rebar Threading Machine

This equipment is widely used in civil engineering, infrastructure projects, and prefabricated construction. It allows for fast and secure connection of steel bars using mechanical couplers for rebar, which enhances the structural integrity of the construction. From high-rise buildings to transportation tunnels, the machine plays a crucial role in reinforcing concrete structures.

Rebar Threading Machine Price in YG Machinery

YG Machinery is a trusted manufacturer of construction equipment. Their rebar threading machine lineup includes not only the basic models but also lengthened and automatic versions for advanced applications.

Besides the rebar thread cutting machine, YG also provides a full range of related equipment including: rebar straightening and cutting machines, threaded rebar coupler, CNC stirrup bending machine, etc. With these machines, you can build a complete processing line for your reinforcement tasks. Contact us today.【WhatsApp/WeChat/Phone/Skype】: +86 13837115193.