Poor surface preparation is the #1 cause of coating failure. Dust, laitance, and uneven grinding lead to weak adhesion, peeling epoxy, and costly rework.

Floor shot blasters provide a faster, cleaner, and more reliable solution. Designed for industrial floors, bridge decks, airport runways, and highway maintenance, shot blasting removes laitance and old coatings efficiently while creating a uniform, high-adhesion surface—ready for epoxy and waterproofing systems in one pass.

✔ Dust-free shot blasting with industrial-grade vacuum

✔ Up to 600 m²/h productivity for large projects

✔ Proven adhesion improvement for epoxy & waterproof layers

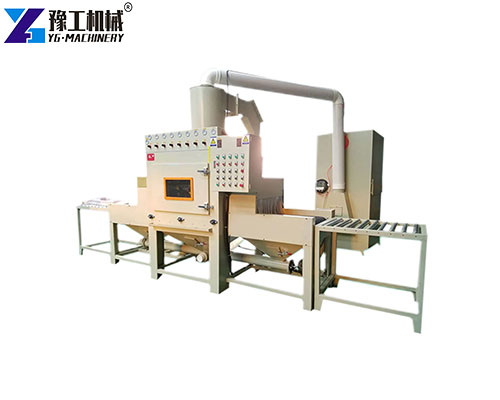

What is a Floor Shot Blaster?

A floor shot blaster uses high-speed steel shot to impact the surface, rapidly breaking down and recovering surface laitance, old coatings, and contaminants, while simultaneously creating uniform roughness, significantly improving the adhesion between the surface and subsequent coatings or waterproofing layers.

In the concrete flooring industry, it’s also known as a concrete floor bead blaster, specifically designed for large-area treatment of factory workshops, warehouses, and anti-slip surfaces.

If the project involves a larger road area, customers will also search for a road shot blasting machine for bridge decks, highways, or airport runways.

Core Advantages of YG Floor Shot Blaster

- High Efficiency and Stability, Consistent Treatment Results

YG’s floor shot blaster uses a high-speed, wear-resistant blasting wheel system, capable of processing 200–500 square meters per hour (depending on the model), 4–6 times more efficient than traditional grinding.

It ensures consistent roughness and controllable depth for both concrete and steel surfaces.

- Fully Enclosed Circulation System, Dust-Free and Environmentally Friendly

Traditional grinding generates significant dust, failing to meet European and American construction standards.

YG shot blasting machines are equipped with industrial-grade filter vacuum cleaners, achieving:

Dust-free construction; Automatic shot circulation; More environmentally friendly and healthier construction.

Ideal for countries with stringent dust control requirements: Italy, Spain, Germany, Australia, the United States, etc.

- Zero damage to the substrate, no structural damage

Shot blasting only affects a thin surface layer, with precise depth control, preventing damage to the concrete structure and avoiding micro-cracks. It is a better alternative to milling machines and grinders.

Applications of YG Floor Shot Blaster

The YG floor shot blaster is widely used for concrete and road surface preparation across industrial, commercial, and infrastructure projects.

- Industrial floor surface preparation

Efficient removal of laitance, oil stains, and old coatings; standard pretreatment equipment before epoxy and polyurethane (PU) flooring installation. - Warehouse, parking lot, and logistics center floors

Creates a uniform surface profile, improving slip resistance and coating adhesion. - Bridge deck waterproofing pretreatment

Cleans concrete bridge surfaces and enhances bonding strength of waterproofing membranes. - Airport runways and port terminals

Removes rubber deposits, aged coatings, and surface contaminants, increasing surface friction and safety performance. - Highways and municipal roads

Suitable for road maintenance and asphalt surface pretreatment; can be used independently or in combination with large road shot blasting machines.

Floor Shot Blaster Parameters

| Model | YG-270(Single) | YG550/600(Double) | YG-850(Double) | |

| Shot Blasting Wheel Diameter | 200mm | |||

| Working width | 270 mm | 550/600 mm | 800 mm | |

| Walking speed | 0.5~20 m/min | 0.5~33 m/min | ||

| Concrete surface cleaning efficiency | ≥180 m2/h | ≥400 m2/h | ≥600 m2/h | |

| Steel plate surface cleaning efficiency | 15-25 m2/h | 75-100 m2/h | 100-160 m2/h | |

| Dust connection pipe diameter | 120 mm | 150 mm | ||

| Suggest the diameter of steel balls | 1.2-1.5 mm | 1.5-1.8 mm | ||

| Steel pill consumption | 10 g/m2 | |||

| Supporting dust collector | Seven-core automatic backflush vacuum cleaner | Eight-core automatic backflush vacuum cleaner | ||

| Shot wheel motor | Power consumption | 11 kW | 11*2 kW | 15*2 kW |

| Input Current | ≤ 15 A | ≤ 22*2 A | ≤ 28*2 A | |

| Walking motor | Power consumption | 0.5 kW | 1.5 kW | |

| Input Current | 1 A | 3 A | ||

| Size (mm) | 1000*300*1100 | 1950*720/775*1400 | 1950*1020*1550 | |

| Weight | 150 kg | 570 kg | 700kg | |

| Power connection requirements | 400V, 50Hz, 100A, CEE socket | |||

Italy Project Case|YG Floor Shot Blaster Delivered to Milan

In 2024, an industrial flooring construction company from Milan, Italy, approached YG. They faced the following challenges:

- The local project required dust-free construction, but the existing grinding machine generated too much dust;

- The concrete floor was hard, resulting in slow processing speed;

- The client complained of insufficient adhesion, causing the epoxy coating to peel easily;

- European equipment was too expensive, and ordering one unit required a 3-4 month delivery time.

After comparing several suppliers in China and Europe, they ultimately chose the YG 330 floor shot blaster + industrial dust extraction system.

Post-delivery results:

- Construction efficiency increased from 120㎡/h to 320㎡/h;

- The entire process was dust-free, meeting Italian environmental requirements;

- The floor roughness was uniform, significantly improving the adhesion of the subsequent epoxy coating;

- YG’s delivery time was only 10 days, and the customer was extremely satisfied.

The customer stated:

“YG’s floor shot blaster helped us secure two large contracts this quarter. The performance is stable, and the dust-free feature is amazing.”

They have now become a long-term cooperative customer of YG in Italy.

Why Choose YG Machinery as Your Shot Blasting Supplier?

- 15+ Years of Professional Manufacturing Experience

YG specializes in road machinery and flooring equipment, exporting its products to over 30 countries, including:

Italy, Australia, Brazil, Poland, Saudi Arabia, Thailand, Malaysia, Chile, etc.

- Complete Model Selection and Customization Services

Available:

- 270mm, 330mm, 550mm shot blasting widths

- Push-type / Self-propelled type

- Industrial vacuum cleaner integrated solutions

- Customized voltages (220V/380V/415V)

- European CE certification

- Direct from the manufacturer, more competitive pricing

YG is a manufacturing factory, not a trading company, providing a stable supply chain and higher cost-effectiveness to meet the global user’s search needs for “shot blasting machine for sale”.

- On-site user training + video guidance + 24/7 after-sales support

Providing full-process technical support from model selection, transportation, installation to construction and commissioning.

Shot Blasting Machine for Sale in YG Machinery

If you need a floor shot blaster that truly improves construction efficiency, meets environmental requirements, and enhances project quality, YG Machinery is your most reliable partner.

Whether you are:

- A flooring construction company;

- A road and bridge maintenance company;

- An industrial floor repair unit;

- An airport runway maintenance team.

YG can provide you with suitable concrete floor bead blaster or large-area road shot blasting machine solutions.