An automatic brick machine is a highly efficient piece of equipment designed for mass production of bricks using advanced PLC control systems. It combines hydraulic pressure, mechanical vibration, and automation to produce high-quality bricks with minimal labor. Ideal for both large-scale construction and small manufacturing units, this machine offers fast molding cycles, reduced material waste, and strong bricks with consistent quality.

Key Features and Specifications

The automatic brick machine is available in multiple configurations to meet various brick sizes and production needs. For example, hollow blocks measuring 400×200×200mm can be produced at a rate of over 11,000 pieces in an 8-hour shift. The equipment includes multi-mold options to produce standard bricks, porous blocks, pavers, and interlocking bricks, depending on the selected mold.

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Working Principle of the Machine

Bricks are formed through a blend of hydraulic power and high-frequency vibration. Raw materials such as fly ash, sand, crushed stone, cement, and water are fed into the machine’s hopper. The mixture is automatically distributed, vibrated, and pressed into molds. A programmable logic controller (PLC) manages the entire cycle—feeding, pressing, demolding, and stacking—ensuring speed and consistency.

Advantages of YG Automatic Brick Machine

This machine offers strong adaptability to various raw materials, including fly ash, slag, and stone dust. It also helps reduce cement usage by optimizing compaction. With its smart control panel and touch screen interface, it’s simple to operate and easy to maintain. The integrated hydraulic station ensures stable pressure while isolating the system from external vibration and dust.

Its intelligent design makes it a preferred choice for companies building a brick manufacturing plant. It not only boosts productivity but also significantly lowers operational costs in the long term.

Applications of Automatic Brick Machine

The machine is suitable for a variety of construction projects. It’s widely used in real estate development, municipal infrastructure, highway construction, and rural housing. With the flexibility to produce multiple brick types, it meets the diverse needs of builders, contractors, and local governments.

Bricks made using this equipment are used for both load-bearing and non-load-bearing walls. Fly ash bricks, for instance, offer excellent insulation, are environmentally friendly, and utilize industrial waste effectively—making the automatic fly ash brick machine a top choice for eco-conscious developers.

Types of Bricks and Raw Materials

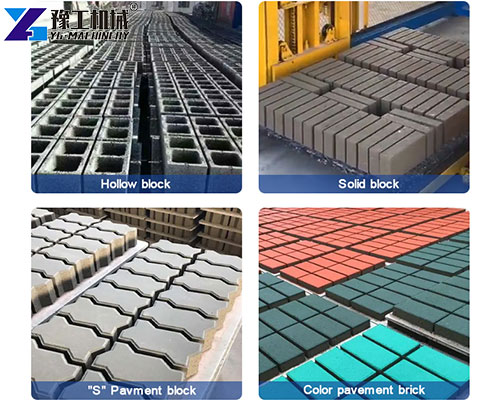

This equipment can produce: Hollow blocks, Solid bricks, Pavers, Interlocking bricks, Porous bricks, etc.

Common raw materials include cement, fly ash, river sand, crushed stone, lime, and water. Depending on availability, it also supports the use of industrial waste and recycled materials, making it a sustainable choice for modern construction.

Affordable Pricing of Automatic Fly Ash Brick Machine

If you’re looking for an automatic brick making machine price, YG Machinery offers competitive rates without compromising quality. Our machines deliver excellent ROI, especially for clients building long-term, large-scale brick production facilities.

Why Choose YG Machinery?

YG Machinery is a trusted manufacturer with over 20 years of experience in construction equipment. We not only produce reliable automatic brick machines but also provide complete solutions for your project. Our after-sales service, technical support, and customization options are unmatched in the industry. We also offer other top-selling products, including: concrete mixer machine with pump, self loading truck mixer, concrete delivery pump, electric stacker lift, concrete block making machine, fly ash brick production line. Contact YG Machinery Today.【WhatsApp/WeChat/Phone】+86 13837115193.