The perception that concrete block production is labor-intensive and environmentally taxing is now outdated. YG’s automatic cement block making machine transforms traditional brickmaking by integrating automation, hydraulic technology, and sustainable raw material use—delivering higher efficiency, better product quality, and lower operational costs.

Advanced Engineering Meets Real-World Demands

YG Machinery’s automatic cement block making machine is built to meet 2023 industry standards for strength, reliability, and automation. Equipped with an intelligent PLC control system and robust hydraulic power unit, the machine performs automatic feeding, molding, and demolding, minimizing manual labor while boosting precision.

Technical Specifications :

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Why Choose Cement Blocks? Stronger, Cleaner, Smarter

Unlike red bricks, cement blocks don’t require high-temperature firing, making them more eco-friendly. They are produced using industrial waste like fly ash, coal gangue, or slag, combined with cement as a coagulant. This composition not only reduces environmental impact but also cuts production costs significantly.

Cement bricks made by YG’s machine offer:

- High compressive strength (MU10–MU30 grades).

- Low water absorption.

- Excellent frost resistance.

- Standard sizing and uniform appearance.

- Low-cost raw materials (up to 80% recycled content).

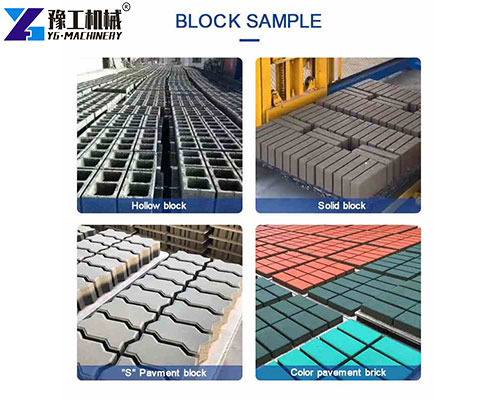

Their application ranges from garden landscaping and sidewalk paving to large-scale residential and commercial building construction. With ongoing urbanization and sustainable construction trends, the demand for cement blocks making equipment continues to rise globally.

Built-In Safety for Secure Operation

Operational safety is a top priority. YG’s machines are equipped with:

- Hydraulic overload protection

- Emergency stop buttons

- Automatic warning systems

- Enclosed control panels with overload alarms

Operators should wear safety gloves and goggles during machine maintenance, avoid direct contact with moving parts, and ensure the system is grounded properly to prevent electrical hazards.

Cost-Effective, Low-Maintenance Automation

The automatic brick machine price depends on configuration and capacity but offers strong ROI due to its low labor requirements, fast production cycles, and reduced raw material costs. Thanks to its durable design, the machine requires minimal maintenance—only routine lubrication and cleaning are needed.

Cementing Your Future with YG Machinery

With decades of experience in smart manufacturing, YG Machinery delivers cutting-edge construction equipment trusted by clients in over 30 countries. Our automatic cement block making machines stand out for their efficiency, intelligent control, and adaptability to local material availability.

Looking to expand your concrete product line or upgrade outdated manual equipment? YG offers tailored solutions and after-sales support to keep your business growing. In addition, YG have: cement brick making moulds, automatic hollow block machine, fly ash brick making machine, concrete brick making machine, etc. Contact YG Machinery today for a free quote and expert consultation.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.