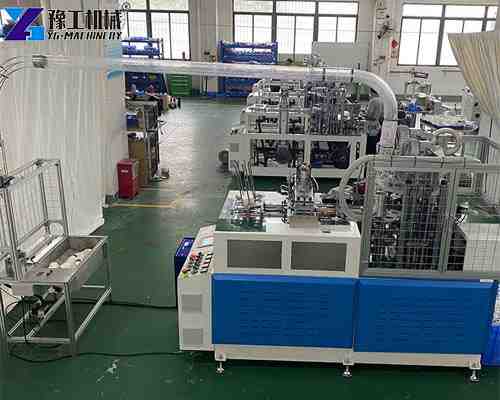

In the modern fast-paced life, coffee cups have become a common item in catering, office and takeaway scenes, etc. YG’s coffee cup making machine is specially designed for the production of disposable paper cups, featuring fast molding speed, convenient operation and excellent quality of finished products, which is widely used in the fields of paper cup factories, catering chain enterprises, packaging product companies and so on. It is widely used in paper cup factories, restaurant chains, packaging companies and other fields. Compared with the traditional cup making machine, this machine combines high efficiency and energy saving, which is suitable for batch automatic production.

YG Coffee Cup Making Machine Parameters (Version 2023)

Users should pay attention to: ensure stable power supply, operators wear protective gloves, clean the ultrasonic welding head in time to avoid the accumulation of impurities and affect the molding quality.

| Model | YG-35 |

| Paper Cup Size | 3-16oz |

| Paper Cup Top Diameter | Min 65mm-max94mm |

| Paper Cup Bottom Diameter | Min45mm-60mm |

| Paper Cup Height | Min60mm-135mm |

| Raw Material | PE-COATED PAPER.RIPPLE PAPER ETC |

| Speed | 80-90pcs/min |

| Speed of 20 hours of stable running per day | |

| Suitable paper weight | 150-350gsm |

| Voltage supply | 220v50hz single phase/ 380v50hz 3-phase(better to use 380v50hz 3-phase)*If the user’s voltage supply is different, please inform us in advance. |

| General power | 4.7KW |

| Net weight | 1500kgs |

| Measurement (mm) | 2150*950*1650MM |

| Cup Side Sealing | Ultrasonic |

| We can customize the machine and mold according to the customer’s requirements. | |

Structure and Working Principle

- This coffee cup making machine consists of paper feeding unit, preheating unit, molding unit, ultrasonic welding, bottom stamping device and upper mouth crimping system.

- Raw paper is automatically fed through the paper guide frame, and after preheating, it enters into the molding area, the side wall is sealed by ultrasonic wave, the bottom paper is synchronously fed into the stamping and then positioned to fit, and the final crimping and shaping is done.

- The whole machine adopts PLC intelligent control, fault self-checking and abnormal automatic alarm to ensure continuous 24 hours stable operation.

Product Advantages and Application Scenarios

YG new generation coffee cup making machine excels in energy saving, consumption reduction and stability.

- Adopting stepping motor to control the paper feeding, the accuracy is improved to within 0.1mm, which effectively reduces the waste of paper;

- Gear transmission design avoids chain loosening problem and prolongs the service life of the equipment;

- Independent lubrication system to reduce the frequency of manual maintenance, reduce operating costs. It is suitable for batch manufacturing of various types of disposable cups such as coffee shop special paper cups, cold drink cups, milk tea cups, supermarket paper cups and so on.

- YG has optimized safety protection measures, such as photoelectric sensing stop device, paper shortage prevention and paper offset alarm, which effectively reduces operation risk and improves production safety.

Coffee Cup Machine Price in YG Machinery

As a leading cup manufacturing machine manufacturer in China, YG Machinery has won favorable comments from customers all over the world by virtue of its technical research and development strength and perfect after-sales service. Our equipment has been exported to Europe, America, Africa, the Middle East, South America and many other countries, and support customization on demand, to help customers reduce the cup machine price budget, and quickly recover investment costs.

In addition to this coffee cup making machine, YG also provides disposable cup making machine, paper bowl machine, paper plate molding machine, paper straw machine, paper bag making machine and other ancillary products to help customers build a complete paper products production line. Contact us to know more details now!【WhatsApp/WeChat/Phone/Skype】+86 13837115193.