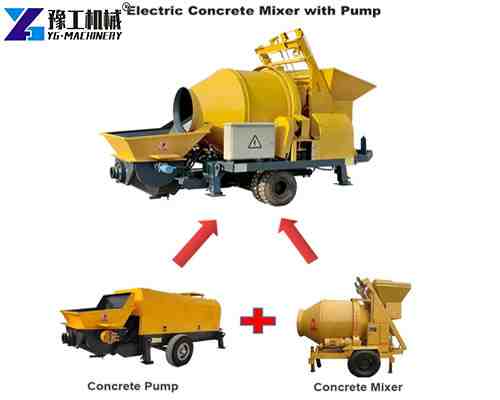

Do you really need to buy a separate mixer and pump for concrete construction? As a matter of fact, concrete mixer and pump is gradually replacing the traditional split equipment and becoming the core equipment for small and medium-sized construction projects. This kind of equipment integrates mixing and pumping, which not only saves labor and equipment costs, but also improves construction efficiency, and is widely used in building construction, rural renovation, tunnel support and other scenarios.

YG Concrete Mixer Pump Core Parameters

As a professional concrete mixer machine manufacturer, YG introduces a new generation of mixer pump equipment, combining the 2023 industry standard, taking into account the performance and operational safety:

| 参数 | JBS30 | JBS40 | JBS30R | JBS40R |

| Theoretical Conveying Capacity(m3/h) | 30/17 | 46/30 | 30/23 | 40 |

| Concrete Conveying Pressure(MPa) | 9 | 10 | 9 | 10 |

| Maximum Conveying Distance(m)Vertical/Horizontal | 120/500 | 140/600 | 120/500 | 140/600 |

| Main Motor Power(kW) | 37 | 45 | 66 | 82 |

| Conveying Cylinder Bore×stroke(mm×mm) | 140×1000 | 180×1000 | 140×1000 | 180×1000 |

| Main Cylinder Bore×Stroke(mm×mm) | 80×1000 | 100×1000 | 80×1000 | 100×1000 |

| Maximum Aggregate Size(mm) | 30 | 40 | 30 | 40 |

| Stirring Motor Power(kW) | 5.5 | 5.5 | 5.5 | 5.5 |

| Feeding Motor Power(kW) | 5 | 5 | 5 | 5 |

| Hopper Capacity(m3) | 0.8 | 0.8 | 0.8 | 0.8 |

| Mixer Discharge Capacity(m3) | 0.45 | 0.45 | 0.45 | 0.45 |

| Mixer Productivity(m3/h) | 10–14 | 10–14 | 10–14 | 10–14 |

| L×W×H(mm) | 4500×2200×2600 (Transportation Height) | 4500×2200×2600 (Transportation Height) | 4500×2200×2600 (Transportation Height) | 4500×2200×2600 (Transportation Height) |

| Host Quality(kg) | 4000 | 4300 | 4800 | 5200 |

Customer Case Show

- Chiang Mai, Thailand: construction of single-family houses in mountainous areas: The customer needs to build more than ten small villas in hilly terrain, traditional pump trucks can not enter, high labor costs. After choosing a 40m³/h electric concrete mixer and pump, the concrete construction time for each house was shortened from 3 days to 1.5 days, and the sloping foundation could be poured accurately.

- Manila, Philippines: Old Urban Pipe Network Upgrading Project: For the infrastructure upgrading project in the city center with restricted site and complicated traffic, the YG diesel-driven mixer pump ran for 8 hours a day to steadily pump concrete through narrow alleys to reach the target area, which won favorable comments from the local contractors.

- Guangxi, China: Construction of a three-story self-built house in a rural area: The farmer purchased a concrete mixer with pump machine for his own use to save budget and improve efficiency. It is easy to operate, requires only 2 people to operate, pumps evenly and smoothly, and shortens the construction period significantly.

Frequently Asked Questions

Q1:Will concrete mixer and pump block the pipe?

A: Generally not. In our experience, using YG equipment, as long as the aggregate size and consistency are well controlled, and the pipes are cleaned regularly, the risk of clogging can be effectively avoided.

Q2: Is the concrete mixer pump price fixed?

A:Price is affected by many factors such as configuration, motor model, customized demand and so on. Generally, the price of standard model is between RMB 18-300,000 yuan, and you can contact customer service for real-time quotation.

Q3: Does it support remote maintenance or intelligent system?

A: Some of the upgraded models have integrated remote diagnostic modules, which can realize AI decision-making suggestions and remote fault prompts, as part of the intelligent transformation.

Usage Tips and Safety Advice

- Be sure to check the cable, hydraulic oil level and control panel before starting the machine to make sure there is no error before operating;

- After each pumping, be sure to clean the delivery pipe and pump chamber to prevent residual slurry from solidifying;

- If working in winter, it is recommended to use a heated mixing drum and anti-freeze additives;

- When using concrete mixer with pump machine, enough working space should be reserved to ensure the safety of mechanical arm extension and pipeline swing.

Industry Trend Observation

Currently, integration is developing rapidly, and station truck pump integration has become the standard mode for small and medium-sized construction sites; the popularity of green equipment is rising, and the energy consumption of pure electric drive mixer pumps is reduced by about 40-60% compared with that of traditional diesel equipment; and in the future, the intelligent system (e.g., GPS positioning, AI ratio optimization) will further enhance the level of construction automation.

Reliable Concrete Mixer Machine Manufacturer – YG Machinery

YG Machinery, as a mature concrete batching plant suppliers and concrete mixer machine manufacturer, has been deeply engaged in the field of concrete equipment for many years, not only providing high-performance mixer pumps, but also customizing a full set of construction solutions. Our equipment has served more than 20 countries and regions with stable operation and high customer satisfaction. In addition, YG offer: mobile concrete batching plant, concrete mixer machine, mortar spraying machine, etc. Contact us to know more details now!【WhatsApp/WeChat/Phone/Skype】+86 13837115193.