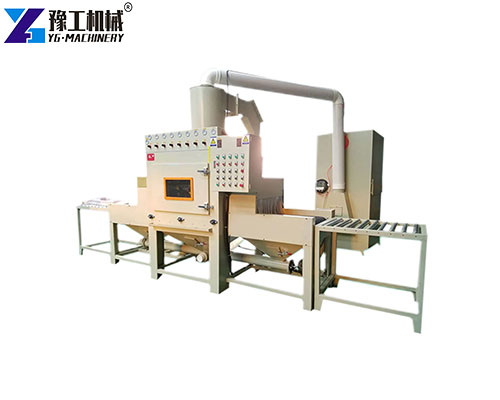

In the field of industrial rust removal and surface cleaning, the traditional sand blasting method is often questioned due to serious dust and pollution. Nowadays, dustless sand blasting machine has brought a cleaning revolution for surface treatment by combining “sand blasting + water mist dust reduction”. This equipment not only excels in rust removal efficiency, but also reaches a whole new level of safety and environmental protection, and is widely used in the fields of ships, bridges, steel structures, stone carving and so on.

YG Dustless Sand Blasting Machine Parameters

YG’s latest generation dustless sand blasting machine integrates the core technology of the 2023 industry standard, and the main parameters are as follows:

| Model | YG-300 | YG-500 | YG-600 | YG-800 | YG-1000 |

| Capacity(L) | 300 | 500 | 600 | 800 | 1000 |

| Diameter(mm) | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1750 | 1750 | 1950 | 2100 | 2200 |

| Work efficiency(m2/h) | 7~15 | 7~15 | 7~15 | 7~15 | 7~15 |

| Working Pressure(Mpa) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Air consumption(6m3/min) | 6 | 6 | 6 | 6 | 6 |

| Weight | 280 | 360 | 420 | 545 | 640 |

Why Choose YG Dustless Sandblasting Machine?

In traditional dry sandblasting, a large amount of dust not only jeopardizes the health of operators, but also pollutes the surrounding environment. YG’s dustless sand blasting machine shows the following advantages in practical application:

- Significantly reduce the dust suspension rate: water mist spraying is synchronized, effectively locking more than 95% of the dust particles.

- Improved construction visibility: no dust obstruction, more accurate and efficient operation.

- Reduced sandblasting rebound: The buffering effect of water can significantly reduce the rebound of abrasive and improve safety.

- Abrasive recycling and reuse: Built-in collection device effectively saves cost and prolongs the service life of the material.

- Suitable for all kinds of metal and non-metal substrates: In our long-term cooperation with customers, such as shipyards, steel fabricators, and cultural relics restoration units, the general feedback is that the performance of the equipment is stable and maintenance is simple.

At the same time, the compact structure of the equipment, easy to transfer, suitable for on-site construction of mobile sandblasting for sale scenarios.

Precautions for Use and Typical Scenes

When operating dustless sand blasting machine, wear professional sand blasting protective clothing, dust mask and earplugs to ensure personnel safety. Before starting the equipment, you should make sure that the grounding is intact, the water source is stable, and the air pressure is moderate, so as to avoid clogging of the equipment or uneven sand blasting due to improper operation.

Common Use Scenarios of Dustless Sand Blasting Machine

- Rust removal and pre-painting treatment of large steel structures;

- Outdoor sculpture and stone surface cleaning;

- Bridge anticorrosion layer stripping and repainting preparation;

- Industrial plant renovation and maintenance;

In commercial applications, YG equipment is also used as commercial sandblasting equipment by rental companies and surface preparation service teams.

Mobile Sandblasting for Sale in YG Machinery

As a professional manufacturer of surface preparation equipment, YG has always been committed to providing stable, efficient and environmentally friendly mechanical solutions. Our dustless sand blasting machine has served customers in Europe, America, the Middle East and 20+ other countries, and has received unanimous praise. Besides this equipment, we also recommend the following related products to meet more construction needs: sand plast machine, dry ice washing machine, etc. For more product details, please contact us.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.