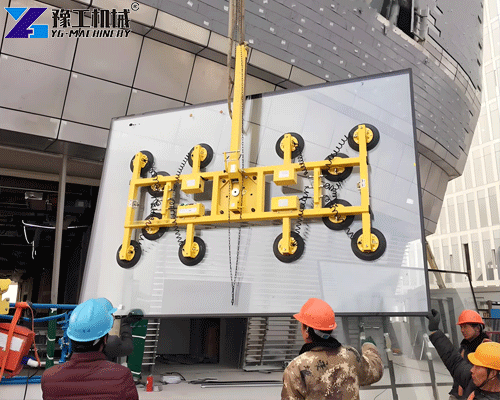

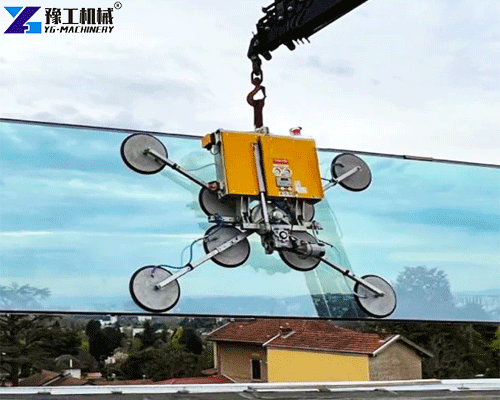

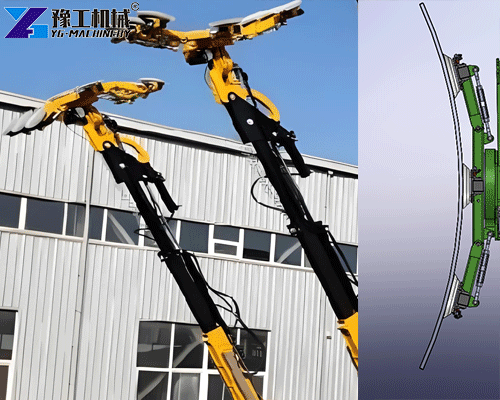

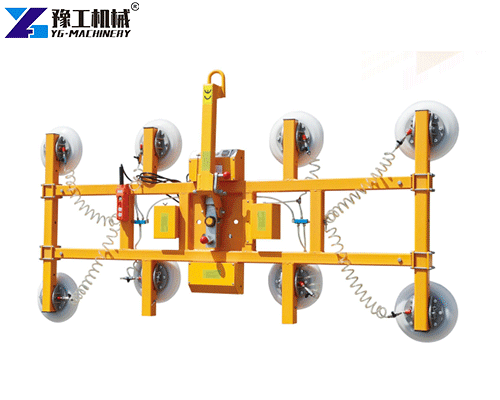

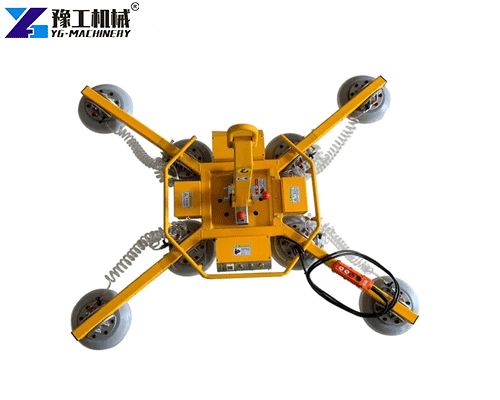

In industries where precision meets fragility—such as construction, decoration, or glass manufacturing—traditional lifting tools fall short. The glass lifter machine from YG Machinery redefines efficiency and safety in glass handling. With vacuum-powered suction and advanced mobility, this solution turns a labor-intensive challenge into a streamlined process. A glass lifter machine can be mounted on a telehandler, spider crane, articulating boom lift, and other lifting equipment for flexible glass handling.

Glass Lifter Machine Parameter

| Parameter | Unit | 400 | 600 | 800 | 1000 | 1200 |

| Load Capacity | kg | 400 | 600 | 800 | 1000 | 1200 |

| Pads Size | mm | Φ300 | Φ300 | Φ300 | Φ300 | Φ300 |

| Pads Qty | pcs | 4 | 6 | 8 | 10 | 12 |

| Battery | V/Ah | 46376 | 46376 | 46376 | 46376 | 46376 |

| Charger | V/A | 46197 | 46197 | 46197 | 46197 | 46197 |

| Rotation | ° | 360 | 360 | 360 | 360 | 360 |

| Tilting | ° | 90 | 90 | 90 | 90 | 90 |

| Suction Frame Size (X) | mm | 920×820 | 2430×1090 | 1980×1610 | 1980×1610 | 1980×1610 |

| Suction Frame Size (H) | mm | 2396×1180 | 2396×1180 | 2396×1180 | 2396×1180 | 2396×1180 |

| Packing Size (X) | mm | 1200×800×520 | 1200×800×520 | 1200×800×520 | 1200×800×520 | 1200×800×520 |

| Packing Size (H) | mm | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 |

Technical Highlights: YG’s Advanced Parameters and Performance Edge

YG’s glass lifter machine is built to meet 2023 international safety and performance standards. Below are three exclusive features that set it apart:

- Max Lifting Capacity – 1000 kg (2204 lbs): Compared to standard models offering 600–800 kg, YG’s machine easily accommodates large-format glass panels, including insulated and laminated types.

- Dual Vacuum Circuit System – EN13155 Compliant: Equipped with a double safety vacuum system, YG machines continue to grip even in partial system failure—an upgrade from single-line competitors.

- 360° Manual Rotation + 90° Tilt Function: Precision positioning with minimal operator effort, essential for high-rise installations and curved façade handling.

These data-backed upgrades make YG’s machine ideal for both construction and manufacturing settings where safety and productivity are non-negotiable.

Application Scenarios: Designed for Demanding Environments

Whether you’re working indoors or 30 floors up, the glass lifter machine adapts to your exact needs. Let’s look at three industry-specific applications:

- High-Rise Curtain Wall Installation

In modern skyscraper construction, glass panels often exceed 3m² in size. Our glass vacuum lifter safely positions these panels at heights over 10 meters, reducing installation time by 30% while ensuring zero glass breakage. - Commercial Glass Door Fitting and Window Panels

In hotel and shopping mall installations, large French windows demand careful handling. YG’s glass vacuum lifting equipment precisely aligns heavy panels with minimal operator input, preventing costly surface scratches and misalignments. - Glass Workshop Automation

Our machines are widely used in production plants for solar panels and automotive glass. The adaptable suction arms and compact chassis enable seamless movement across workshops—boosting productivity while maintaining quality. Interested buyers frequently ask about the glass vacuum lifter price for such bulk-use scenarios, and YG provides customized quotes based on volume and feature needs.

How to Choose the Right Glass Lifter Machine?

Choosing the correct lifter isn’t just about load capacity—it’s about match-fit for your use case. Customers should evaluate:

- Workspace Access: Does your site require compact maneuverability or long-reach lifting arms?

- Suction Cup Configuration: Select the number and diameter (e.g., Ø300mm) based on the panel size and surface smoothness.

- Battery and Power Systems: For daily factory use, dual 120AH batteries offer sustained operation with fewer downtimes.

- Control Interface: Remote vs manual controls—projects with limited staffing benefit from automated, sensor-based lifting.

Customer Case Studies

YG Glass Lifter Machines have been successfully exported to multiple countries, demonstrating their reliability and effectiveness in diverse scenarios:

- Saudi Arabia: Used for high-rise curtain wall glass installation, equipped with a dual vacuum circuit system for safe transportation and installation of large glass panels.

- South Africa: Used for commercial building glass door and window installation, the company reports a nearly 40% reduction in glass breakage and an approximately 25% increase in construction efficiency.

- Australia: Used for automated loading and unloading of large-format glass panels in glass processing plants, offering stable operation during night shifts and easy maintenance.

FAQ about Glass Lifter Machine

Q1: What is the price of a glass lifter machine?

A1: The price depends on the model, load capacity, number of suction cups, rotation and tilt functions, and export destination. YG provides factory quotes. If you provide the weight/size/country of the glass you wish to transport, we can quickly provide a rough quote.

Q2: What safety standards/certifications does it meet?

A2: Our glass lifter machines are equipped with a dual vacuum circuit system (compliant with EN13155/ISO standards) with pressure monitoring, safety alarms, and emergency shutoff features to ensure safe operation.

Q3: What are the maintenance requirements and lifetime?

A3: Suction cups are consumable parts and are generally replaced annually depending on frequency of use. Maintenance intervals for major components, such as batteries and vacuum pumps, are typically 1–3 years. We provide spare parts and technical support.

Q4: Can it be shipped to Africa/Middle East/South America/Asia?

A4: Yes. YG has extensive export experience and can provide export packaging and handle relevant documentation. We can also assist with shipping and customs clearance.

Q5: How much weight/size glass can it lift and handle?

A5: Our models offer retract/extend load capacities ranging from 300kg to 800kg, with a choice of suction cup numbers and diameters. They are suitable for everything from standard glass panels to large curtain wall glass. Custom designs are available for larger loads.

Working Principle: Reliable Vacuum-Based Technology

The glass lifter machine operates using negative pressure. A vacuum pump extracts air between the suction cups and the glass surface, creating firm adhesion. Once secured, the mechanical arm lifts, rotates, or tilts the panel into position.

Safety First: YG’s machines include pressure sensors, overload alarms, and emergency stop systems. Suction power is monitored in real-time, ensuring operational safety even under high load conditions. (Optional: Ask if you’d like a working principle diagram added.

Why Choose YG?

At YG Machinery, our focus is precision-built lifting solutions that meet global safety standards. With over 20 years in equipment manufacturing, we’ve served industries in 30+ countries with reliable, easy-to-operate machinery. Looking for similar lifting tools? Check out: glass-robot, etc. Request a Free Quote Today! Contact us at(WhatsApp/WeChat/Phone/Skype) +86 13837115193.