A glass lifting robot is a specialized material-handling machine designed to safely lift, move, and precisely position glass panels in construction, manufacturing, and installation environments. It reduces labor risk, improves accuracy, and enables efficient handling of large or fragile glass units.

Glass Lifting Robot Parameters

| Model Type | YG-LD-300 | YG-LD-400 | YG-LD-500 | YG-LD-600 | YG-LD-800 | |

| Load Capacity | 300kg(retract)150kg(extend) | 400kg(retract)200kg(extend) | 500kg(retract)250kg(extend) | 600kg(retract)300kg(extend) | 800kg(retract)400kg(extend) | |

| Lifting Height | 3500mm | 3500mm | 3700mm | 3700mm | 4500mm | |

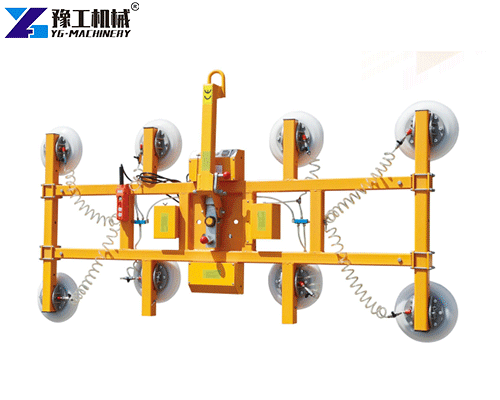

| QTY of Suction Cap | 4pcs | 4pcs | 6pcs | 6pcs | 8pcs | |

| Rubber Suction Cap | 300mm | Ø300mm | Ø300mm | Ø300mm | Ø300mm | |

| Maintenance-free Battery | 2x12V/80AH | 2x12V/100AH | 2x12V/120AH | 2x12V/120AH | 2x12V/120AH | |

| Battery Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | |

| Drive motor | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | |

| Lifting Motor | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/12L | |

| Chassis L*W | 2660*810mm | 2660*810mm | 2800*810mm | 2800*810mm | 2800*810mm | |

| Driving Wheel | Ø250x80mm | Ø250x80mm | Ø300x100mm | Ø300x100mm | Ø300x125mm | |

| Packing Size(mm) | 2560*1030*1700 | 2560*1030*1700 | 2580*1050*1700 | 2580*1050*1700 | 3000*1250*2300 | |

| N.W/G.W | 1100/1150kg | 1280/1330kg | 1300/1350kg | 1400/1450kg | 1600/1650kg | |

| Loading Qty | 1x20GP/40GP: 6SETS/12SETS | |||||

| Movement | Automatic(4 kinds) | 1. The suction cup frame flips 180° electrically. 2. The support plate automatically retracts. 3. Hydraulic arm lifts electrically. 4. The base of the whole machine moves 100-150mm horizontally. | ||||

| Manual (2kinds) | 1. The suction cup holder can be manually rotated 90 degrees (electrically powered optional). 2. The suction cup holder can be manually rotated 360 degrees (electrically powered optional). | |||||

| Usages | Mainly used for the handling, movement, and installation of materials such as glass, marble, wood, iron plate, etc. | |||||

What Problems Does a Glass Lifting Robot Solve?

Handling glass panels presents several challenges:

- High risk of breakage and worker injury

- Increasing glass size and weight in modern buildings

- Limited precision when using cranes or forklifts

- Tight installation spaces and finished façades

A glass lifting robot addresses these issues through vacuum-based lifting, controlled movement, and fine positioning.

Main Types of Glass Lifting Robots

Glass lifting robots are classified based on mobility, control method, and application environment.

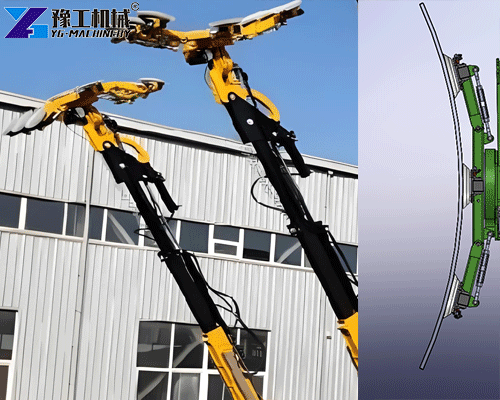

- Mobile Glass Lifting Robots

Designed for indoor and outdoor job sites, these units use wheels or tracks to move glass panels across uneven surfaces. They are commonly used in commercial glazing projects and factories.

- Robotic Vacuum Lifters

These systems focus on precise vertical and horizontal alignment. Many models integrate with cranes or frames and are often referred to as glass vacuum lifting equipment in industrial settings.

- Compact Installation Robots

Smaller machines are used in confined spaces such as elevators, interior partitions, and shopfront installations. They emphasize maneuverability and fine control.

Vacuum Pad Configurations: X-Type vs. H-Type

Glass lifting robots typically use two main suction pad layouts.

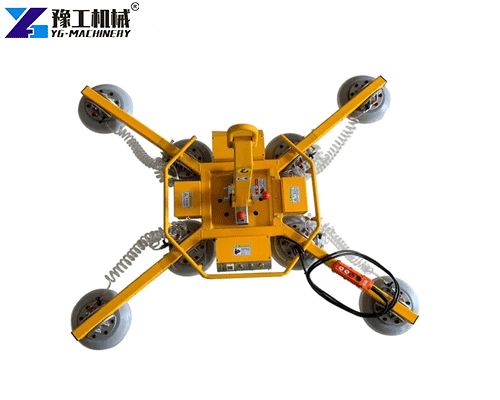

X-Type Vacuum Pad

- Flexible layout for irregular or curved glass

- Better load distribution for asymmetric panels

- Suitable for façade glass and architectural designs

H-Type Vacuum Pad

- Stable configuration for standard rectangular glass

- Ideal for flat panels and insulated glass units

- Common in factories and repetitive installation work

Both configurations support flat and curved glass, depending on pad material and spacing.

Key Features of a Modern Glass Lifting Robot

A professional glass lifting robot usually includes:

- Dual or independent vacuum circuits for safety

- Electric or hydraulic drive systems

- Remote or joystick control for precise movement

- Adjustable arms for different glass dimensions

- Non-marking wheels for indoor environments

These features improve stability during lifting and accuracy during final placement.

Typical Application Scenarios of Glass Vacuum Lifting Equipment

Glass lifting robots are widely used across industries:

- Curtain wall and façade installation

- Window and door manufacturing

- Automotive and rail glass handling

- Furniture and appliance glass assembly

In commercial projects, they are often evaluated alongside glazing robot for sale options when contractors plan equipment upgrades.

How to Choose the Right Glass Lifting Robot?

Selecting the right model depends on practical project requirements rather than brand alone.

Key Selection Factors:

- Glass weight and size: Determines lifting capacity and pad layout

- Glass shape: Curved or flat panels affect vacuum configuration

- Working environment: Indoor floors vs. outdoor construction sites

- Precision requirement: Fine alignment vs. bulk movement

- Transport and storage needs: Compact design vs. heavy-duty frame

For contractors comparing solutions, glass lifting machine for sale listings should always be reviewed together with technical configuration details.

Safety and Efficiency Considerations

Modern glass lifting robots are designed to meet international safety standards. Vacuum loss alarms, backup systems, and emergency stop functions are critical for on-site compliance and risk reduction.

Compared with manual handling, productivity improvements of 25–40% are common in repetitive glazing tasks.

Why Factory-Direct Supply Matters?

Purchasing directly from a manufacturer allows:

- Better configuration matching

- Shorter lead times

- Clear technical documentation

- Lower overall equipment cost

YG Machinery supplies factory-built glass lifting robots with configurable vacuum systems and application-based design, offering reliable performance for professional users.

FAQ about Glass Lifting Robot

Can one machine handle both curved and flat glass?

Yes. With appropriate suction pads and adjustable arms, both glass types can be handled safely.

What affects the total cost?

Lifting capacity, control system, vacuum configuration, and mobility options influence pricing.

Is operator training required?

Basic training is usually completed within one working day.

Are spare parts standardized?

Most vacuum and control components follow international standards for easy replacement.

Glazing Robot for Sale in YG Machinery

A glass lifting robot is a practical and safety-focused solution for modern glass handling tasks. By understanding robot types, vacuum pad configurations, and real application needs, buyers can select equipment that improves efficiency, reduces risk, and fits long-term project requirements.