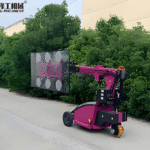

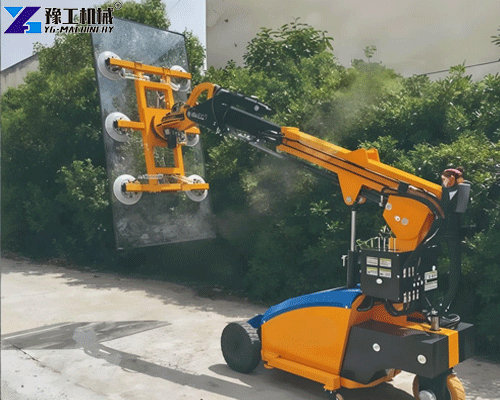

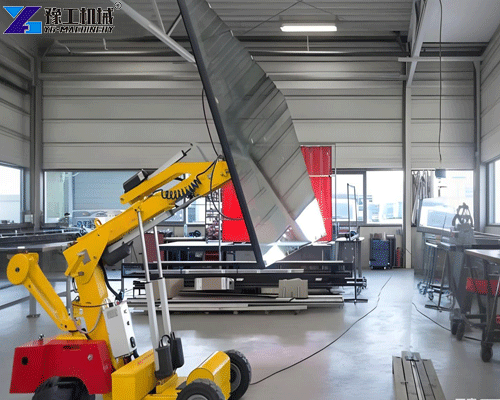

A glass robot vacuum lifter is an advanced automation solution designed to lift, transport, and install glass panels of various sizes with precision and safety. Unlike traditional manual handling, this equipment minimizes the risk of breakage, reduces labor costs, and improves productivity for construction and industrial glass projects.

Glass Robot Vacuum Lifter Parameters

| Model Type | YG-LD-300 | YG-LD-400 | YG-LD-500 | YG-LD-600 | YG-LD-800 | |

| Load Capacity | 300kg(retract)150kg(extend) | 400kg(retract)200kg(extend) | 500kg(retract)250kg(extend) | 600kg(retract)300kg(extend) | 800kg(retract)400kg(extend) | |

| Lifting Height | 3500mm | 3500mm | 3700mm | 3700mm | 4500mm | |

| QTY of Suction Cap | 4pcs | 4pcs | 6pcs | 6pcs | 8pcs | |

| Rubber Suction Cap | 300mm | Ø300mm | Ø300mm | Ø300mm | Ø300mm | |

| Maintenance-free Battery | 2x12V/80AH | 2x12V/100AH | 2x12V/120AH | 2x12V/120AH | 2x12V/120AH | |

| Battery Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | |

| Drive motor | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | |

| Lifting Motor | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/12L | |

| Chassis L*W | 2660*810mm | 2660*810mm | 2800*810mm | 2800*810mm | 2800*810mm | |

| Driving Wheel | Ø250x80mm | Ø250x80mm | Ø300x100mm | Ø300x100mm | Ø300x125mm | |

| Packing Size(mm) | 2560*1030*1700 | 2560*1030*1700 | 2580*1050*1700 | 2580*1050*1700 | 3000*1250*2300 | |

| N.W/G.W | 1100/1150kg | 1280/1330kg | 1300/1350kg | 1400/1450kg | 1600/1650kg | |

| Loading Qty | 1x20GP/40GP: 6SETS/12SETS | |||||

| Movement | Automatic(4 kinds) | 1. The suction cup frame flips 180° electrically. 2. The support plate automatically retracts. 3. Hydraulic arm lifts electrically. 4. The base of the whole machine moves 100-150mm horizontally. | ||||

| Manual (2kinds) | 1. The suction cup holder can be manually rotated 90 degrees (electrically powered optional). 2. The suction cup holder can be manually rotated 360 degrees (electrically powered optional). | |||||

| Usages | Mainly used for the handling, movement, and installation of materials such as glass, marble, wood, iron plate, etc. | |||||

Key Components of Glass Robot Vacuum Lifter

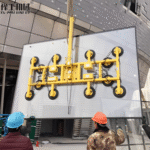

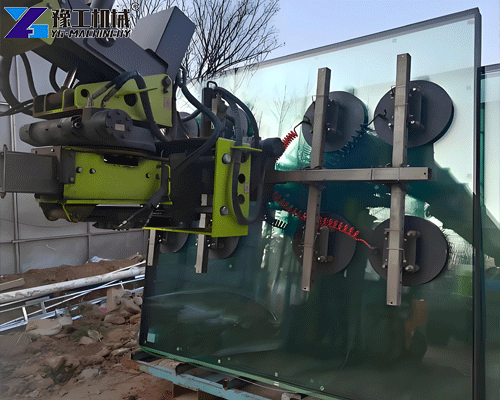

- Vacuum suction pads: Securely hold glass sheets of different thicknesses.

- Hydraulic or electric lifting mechanism: Provides smooth vertical movement.

- Rotating and tilting system: Enables precise positioning for curtain walls, windows, or prefabricated structures.

- Mounting interface: Compatible with forklifts, telescopic arms, or spider cranes for increased reach and flexibility.

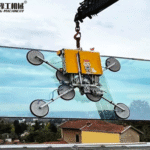

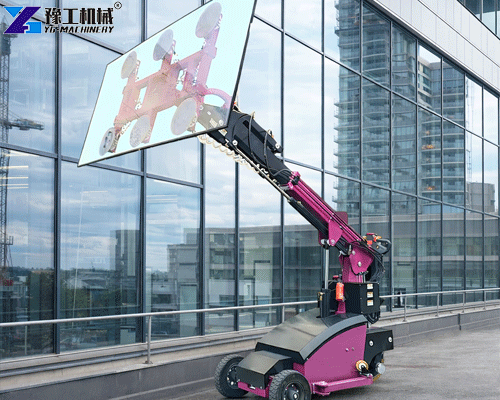

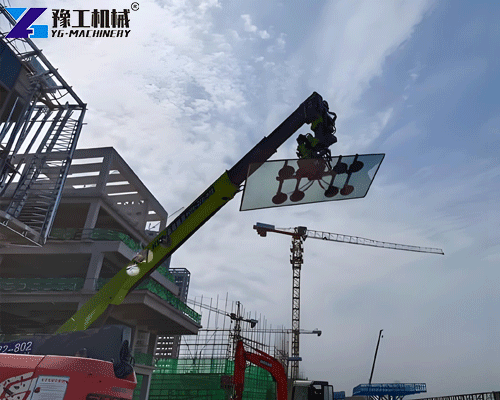

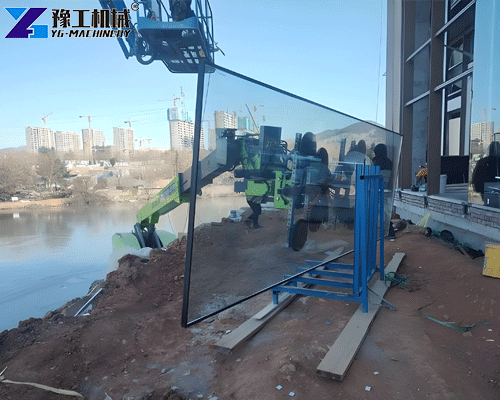

Glass Robot = Glass Lifter Machine + Mobile Base (Telehandler, Telescopic Boom, Spider Crane)

The glass lifter machine can be detached from the glass robot and easily mounted on a telescopic forklift, telescopic boom, or spider crane, allowing safe and efficient lifting and transport of glass panels. This modular design provides flexibility, combining precise vacuum lifting with the mobility of a telescopic forklift for various construction or warehouse applications.

Unique Advantages of a Glass Lifting Robot

When considering a glass lifting robot for sale, there are several unique benefits that make this investment worthwhile:

- Enhanced Safety: Reduces the risk of accidents and injuries associated with manual glass handling.

- Precision Placement: Allows exact alignment for curtain walls, large windows, and architectural glass panels.

- Versatility: Can lift glass, mirrors, solar panels, acrylic sheets, and other flat fragile materials.

- Time Efficiency: One operator can handle large panels alone, improving project speed and reducing labor costs.

- Reduced Damage: Vacuum suction ensures no scratches, cracks, or chips during lifting and transport.

- Mobility Options: Can be mounted on forklifts, telescopic booms, or spider cranes, making it suitable for both indoor and outdoor projects.

How to Choose the Right Glass Robot?

Selecting the correct glass robot depends on your project requirements and work environment:

- Glass Size and Weight: Check the lifting capacity and suction pad dimensions.

- Worksite Access: For tight urban construction sites, a compact model with forklift compatibility may be ideal.

- Mobility Needs: Consider a glass robot that can mount on telescopic or spider cranes for high-rise installation.

- Power Source: Electric models are preferred for indoor use due to zero emissions, while hydraulic systems offer higher lifting power outdoors.

- Automation Features: Some glass robots provide remote control operation or programmable tilting angles for repetitive installations.

Factors Affecting Glazing Robot Price

When searching for a glazing robot price, several factors influence the cost:

- Lifting capacity and maximum panel size

- Type of mobility (forklift-mounted, telescopic arm, or spider crane)

- Vacuum system quality and number of suction pads

- Automation level and safety features

- Brand reputation and after-sales support

Investing in a high-quality glass lifting robot ensures durability, safety, and lower long-term maintenance costs.

Applications of Glass Lifting Robots

These machines are widely used in:

- Commercial Construction: Curtain walls, large windows, office glass panels.

- Prefabricated Building Installation: Fast, safe, and precise panel placement.

- Industrial Glass Processing: Handling mirrors, solar panels, and specialty glass sheets.

- Renovation Projects: Replacing large glass panels in high-rise buildings.

Why Choose YG Machinery Glass Robots?

At YG Machinery, our glass lifting robots for sale are designed to meet professional requirements while being user-friendly. Advantages include:

- Compatibility with forklifts, telescopic booms, and spider cranes

- Wide range of lifting capacities and panel sizes

- Durable vacuum systems for long-term operation

- International safety certifications

- Strong global after-sales service

By choosing YG, customers benefit from a glass robot vacuum lifter that is flexible, safe, and efficient for multiple glass handling applications.