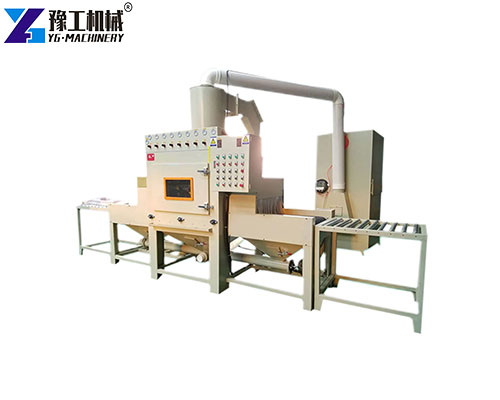

In the field of high-efficiency rust removal, surface pretreatment and other heavy industries, the industrial sand blasting machine has long been more than a “sand blasting machine” in the traditional sense. It is a new type of industrial sand blasting solution that integrates automation control, energy-saving design and multi-media adaptation. It is suitable for bridge renovation, ship hull descaling, steel structure pre-painting treatment and other scenarios, and is the main equipment for industrial level cleaning operation.

YG Sand Blasting Equipment Parameters

| Machine models | YG400 | YG500 | YG600 | YG700 | YG800 | YG900 | YG1000 |

| Diameters(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1150 | 1150 | 1150 | 1250 | 1700 | 2000 | 2000 |

| Volume(cubic meter) | 0.26 | 0.26 | 0.26 | 0.3 | 0.6 | 0.8 | 1 |

| Pressure(Mpa) | 0.4-8 | ||||||

| Air consumption(cubic meter per minute) | 3 | ||||||

Three Advantages: More Than Just “blasting”

Feedback from customers shows that many traditional equipment has low cleaning efficiency when facing high hardness oxidized layer, while YG’s industrial sand blasting system can be finely adapted to different materials through adjustable pressure design. Compared with the common commercial sand blasting machine, it is superior in durability and process precision.

For example, in the treatment of welded parts, the dual-channel sand blasting ports are designed to cover the weld seam and the base metal area simultaneously, which not only improves the speed, but also avoids the secondary oxidation. The general feedback from customers is that it is easier to attach coatings to the surface after treatment, and the rework rate of post-processing is significantly reduced.

Frequently Asked Questions (FAQ)

Q: What materials can be sprayed?

A: In addition to the traditional quartz sand, we also support a variety of media such as steel shot, glass beads, aluminum oxide, etc., to meet different cleaning needs.

Q: How is it different from wet blasting?

A: While wet blasting equipment is suitable for use in environments with strict dust control, industrial dry blasting is more efficient at treating highly adherent rust and oil, and requires no additional drying process after drying.

Q: Is it difficult to operate?

A: All operation buttons are labeled in Chinese with clear start-up sequence, and the maintenance window is designed with tool-less quick-open for easy maintenance.

How Do I Maintain My Industrial Blasting Equipment?

It is generally recommended to check the nozzles for wear and tear every 80 hours and to clean the sand tank weekly for residual sand and impurities. Especially when using mobile sandblasting equipment or vehicle-mounted sandblasting, the air pressure system should be bled in time after operation to avoid residual pressure bursting. The compressed air should use oil-water separator and drain regularly to prevent moisture from clumping when sandblasting.

Why Choose YG Industrial Sand Blasting Machine?

Over the past decade, YG has provided industrial sand blasting machine for sale solutions to customers in 20+ countries. Our machines are not only ruggedly built and precisely controlled, but also support customized blasting bins and automatic recycling systems to fit different plant layouts and safety standards.

If you are looking for a long-term reliable and cost-effective surface treatment equipment, welcome to contact us. Our engineers will recommend the most suitable industrial sand blasting solution according to your site conditions. In addition, YG offers: automatic wet sand blasting machine, crawler type mobile sand blasting machine, dust-free integrated sand blasting room, high pressure air compressor, etc. To get a quote or customized solution immediately.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.