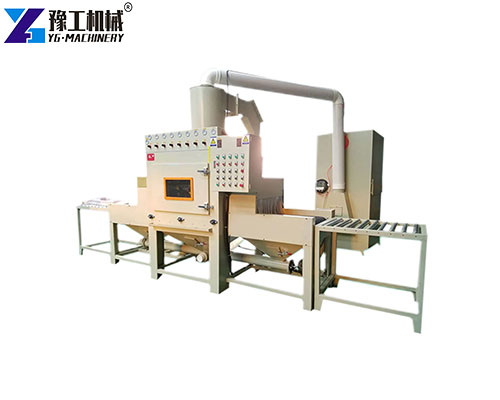

Mobile sandblasting machine is a kind of movable surface treatment equipment, which is used to clean the rust, paint residue and oxidized skin and other impurities on the metal surface. Compared with traditional equipment, this type of sandblasting machine is flexible and convenient, and is suitable for use in construction sites, ship repair yards and large-scale steel structure factories.

YG Mobile Sand Blasting Machine Parameters

| Machine models | YG400 | YG500 | YG600 | YG700 | YG800 | YG900 | YG1000 |

| Diameters(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1150 | 1150 | 1150 | 1250 | 1700 | 2000 | 2000 |

| Volume(cubic meter) | 0.26 | 0.26 | 0.26 | 0.3 | 0.6 | 0.8 | 1 |

| Pressure(Mpa) | 0.4-8 | ||||||

| Air consumption(cubic meter per minute) | 3 | ||||||

Why Choose YG’s Mobile Sand Blasting Machine?

We have found in years of customer feedback that ordinary portable blasting machine is difficult to balance between mobility and stability. YG’s mobile sandblasting machine excels in both aspects. The machine body is equipped with industrial-grade universal wheels and fixing devices to ensure flexible transportation and stable sandblasting.

In addition, the machine can be equipped with a variety of abrasives, such as steel shot, glass beads, brown corundum, etc. It is suitable for steel components, ship hulls, boilers, casting pre-treatment, and is even widely used in denim washing processing. We have customers who use it for bridge coating refurbishment and container interior rust removal, with stable and reliable feedback.

Use Tips and Operation Safety Suggestions

From the field experience, it is recommended that users must complete three checks before officially using the mobile sandblasting machine: first, whether the pressure setting of the gas source is stable at 0.5-0.6MPa; second, whether the abrasive filling is even, to avoid rapid dumping and blockage; third, the sandblasting gun should be oriented at a 45-degree angle to the workpiece, in order to achieve a higher cleaning efficiency.

Wear protective mask and sand blasting suit during operation, turn off the power supply and air source after operation, empty the residual pressure, and then carry out daily cleaning. Regular replacement of nozzles and inspection of filtration devices will help prolong the service life of the equipment. According to the maintenance manual provided by YG, the maintenance cycle is about once a month.

Mobile Sandblasting Equipment for Sale in YG Machinery

As a manufacturing plant specializing in surface treatment equipment, YG has provided high-quality mobile sandblasting equipment for sale solutions to more than 20 countries around the world. Our products are widely used in heavy industries, railroads, ships and construction projects, and have obtained CE and ISO9001 certificates. In addition, we also provide the following related products: dustless sand blasting machine, self loading concrete mixer, crawler concrete pump, etc. Contact us today.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.