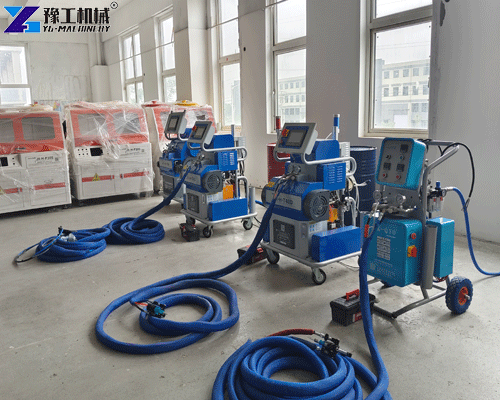

Polyurethane foaming machines are compact, easy-to-use systems designed for on-site insulation, waterproofing, and protective coating applications. Unlike industrial PU foaming machines, these small units provide flexibility, mobility, and reliable spraying performance for localized construction, renovation, and energy-saving projects.

Polyurethane Foaming Machine Parameters

| Model | YG-H-T50 | YG-H5600T | YG-H-T40 | YG-H5600 | YG-Q30 | YG-IIIH |

| Power Supply | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/220V | 380V/220V |

| Heating Power | 25 kW | 25 kW | 22 kW | 22 kW | 15 kW | 9.5 kW |

| Total Power | 29 kW | 29 kW | 26 kW | 26 kW | 15.5 kW | 9.5 kW |

| Drive Type | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Pneumatic | Pneumatic |

| Material Output | 2–8 kg/min | 2–8 kg/min | 2–12 kg/min | 2–12 kg/min | 2–10 kg/min | 2–10 kg/min |

| Air Supply | ≥0.6 m³/min | ≥0.6 m³/min | ≥0.6 m³/min | ≥0.6 m³/min | 0.5–1 MPa ≥1 m³/min | 0.5–0.8 MPa ≥0.9 m³/min |

| Max Output Pressure | 36 MPa | 36 MPa | 36 MPa | 36 MPa | 28 MPa | 25 MPa |

| A/B Ratio | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 |

| Heating Temperature Range | 0–85°C | 0–85°C | 0–85°C | 0–85°C | 0–85°C | 0–80°C |

| Packaging Size (LWH) | 1350×1150×1650 mm | 1350×1150×1650 mm | 1250×1050×1500 mm | 1250×1050×1500 mm | 850×850×1650 mm | 850×850×1650 mm |

| Gross Weight | 420 kg | 420 kg | 350 kg | 350 kg | 200 kg | 205 kg |

| Air Compressor | – | 4 kW, 0.5 m³/min | 4 kW, 0.5 m³/min | – | 7.5 kW, 0.9–1.0 m³/min, 8 bar | – |

Key Advantages of Small Polyurethane Spray Machines

- Compact & Portable: Easy to transport and set up for small or renovation projects.

- Stable Heating & Accurate Mixing: Ensures consistent A/B ratio and uniform foam density.

- Reliable Spraying Performance: Low failure rate and continuous operation for on-site work.

- Energy-Efficient Operation: Reduces power and maintenance costs for small-scale applications.

- Multi-Material Compatibility: Supports insulation foam and protective coatings on roofs, walls, pipes, and tanks.

Applications of Polyurethane Foaming Machine

- Building Insulation: Walls, roofs, attics, container houses.

- Roof Waterproofing: Flat roofs, metal roofs, repair and renovation projects.

- Pipe and Tank Insulation: Thermal protection and condensation control.

- Localized Renovation Projects: Small-scale projects, apartments, and buildings with limited space.

Case Study: Mexico Insulation Project

In 2025, a contractor in Mexico used YG’s small polyurethane spray machine for building insulation. Previous methods were manual and inconsistent, causing uneven foam layers and low efficiency.

Results after deploying the machine:

- Spraying Efficiency: Increased project speed by 30% compared to manual methods.

- Uniform Foam Quality: Consistent density improved thermal insulation performance.

- Easy Operation: Operators mastered the machine quickly with minimal training.

- Mobility & Flexibility: Compact design allowed easy movement between sites.

Customer feedback:

“YG’s small polyurethane spray machine made our insulation work faster, more consistent, and much easier to manage on-site.”

FAQs about Small Polyurethane Spray Machines

Q1: What materials are suitable?

A: Two-component polyurethane foam and coatings for insulation and protective applications.

Q2: Can it handle large projects?

A: Best suited for small to medium-scale projects; multiple machines can be combined for larger areas.

Q3: Is operation complicated?

A: No, it features an intuitive interface and minimal training requirements.

Q4: Are maintenance costs high?

A: No, key components are durable; routine maintenance is simple and low-cost.

Q5: How to get a quote?

A: Click the “Request a Quote” button or contact us via WhatsApp/email for a customized solution.

Contact YG Machinery

As a professional manufacturer, YG Machinery provides small polyurethane spray machines for insulation and coating applications worldwide. Our machines are compact, reliable, and energy-efficient, backed by full technical support and after-sales service. Contact us today: WhatsApp/WeChat/Phone/Skype: +86 13837115193.