As industrial flooring, road maintenance, and surface preparation standards continue to rise, contractors, factories, and construction companies are looking for faster, cleaner, and more cost-effective solutions. This is where the shot blasting machine becomes essential. However, buyers often ask the same question before purchasing: What is the real shot blasting machine price, and how do I choose the right model without overpaying?

This article breaks down price factors, best-use scenarios, and cost-performance analysis, while also helping you choose the right shot blaster for sale with confidence.

Shot Blasting Machine Parameters

| Model | YG-20 | YG-30 | YG-40 | YG-60 |

| Spraying distance | 20m | 30m | 40m | 60m |

| Engine | electric | electric | electric | electric |

| Electric | 380V/50HZ,3 phase | 380V/50HZ,3 phase | 380V/50HZ,3 phase | 380V/50HZ,3 phase |

| Fan motor | 3kw | 3kw | 4kw | 11kw |

| Steering motor | 2*1.5kw | 2*1.5kw | 2*1.5kw | 2*1.5kw |

| Pump motor | 1.5kw | 1.5kw | 2.5kw | 7.5kw |

| Horizontal angle | 360° | 360° | 360° | 360° |

| Vertical angle | Minus10°-55° | Minus10°-55° | Minus10°-55° | Minus10°-55° |

| The nozzle | 8 | 10 | 16 | 22 |

| Cylinder material | Q235 Carbon steel | Q235 Carbon steel | Q235 Carbon steel | Q235 Carbon steel |

| Bucket | 460L | 480L | 800L | |

| Water consumption | 1000L/h | 1500L/h | 3000L/h | 7500L/h |

| Recycled water pipe | 1400mm | 1400mm | 1400mm | 1400mm |

| The machine size | 1170*940*1700mm | 1170*940*1800mm | 1650*1200*2200mm | 1700*1200*2200mm |

| Weight | 200kg | 250kg | 300kg | 350kg |

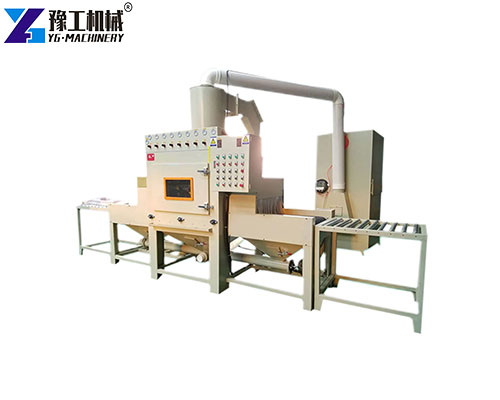

What Is a Shot Blasting Machine Used For?

Shot blasting machines are widely used for removing laitance, cleaning concrete surfaces, roughening industrial floors, increasing coating adhesion, and preparing roads for marking or resurfacing. Compared with manual grinding, they offer:

- Higher efficiency;

- Better consistency;

- Minimal dust pollution;

- Lower labor cost;

- Longer-lasting surface treatment.

For buyers who want a compact and multifunctional solution, the concrete floor bead blaster is especially popular.

Concrete Floor Bead Blaster: Key Applications & Benefits

A concrete floor bead blaster is a specialized form of shot blasting machine designed for fine-profile blasting and high-adhesion surface preparation. It is widely used in:

- Factory and Warehouse Floors

Creates a perfectly roughened surface for epoxy coatings, polyurethane floors, or anti-slip industrial flooring. - Parking Lots and Garages

Removes surface laitance, oil stains, and weak concrete layers, improving coating durability and skid resistance. - Road Surface Preparation

Prepares asphalt or concrete before pavement resurfacing, waterproof coating, or road marking. - Bridge Deck Treatment

Ensures uniform roughness for waterproof membranes, greatly improving bonding strength and safety. - Airport Runways

Removes rubber deposits, increases friction, and restores surface texture with high precision.

Customers prefer bead blasters because they offer high-quality surface profiles, minimal dust, and consistent blasting results, especially for contractors working on thin-coating projects or precision bonding applications.

What Determines the Shot Blasting Machine Price?

The shot blasting machine price varies widely depending on specifications, power, and intended application. Below are the major factors influencing cost:

- Blasting Width & Productivity

- Small units (200–350 mm width): budget-friendly;

- Medium units (400–550 mm width): most common for industrial floors;

- Large units (600–850 mm width): used for highways, airports, and large factories;

- Wider machines mean faster progress, higher efficiency, and higher cost.

- Power Type & Motor Configuration

Machines with higher kW motors blast harder concrete and achieve deeper profiles, increasing the price. - Dust Collection System

A strong vacuum system is critical—it affects both safety and performance.

High-efficiency cartridge filters or cyclone dust collectors increase the cost but dramatically reduce dust pollution. - Steel Shot Consumption & Recycle System

Advanced recycling and separation systems reduce steel shot consumption and operation cost, but they increase the upfront machine price. - Brand, Build Quality & Warranty

Well-engineered shot blasting machines use durable materials, stable blast wheels, and reinforced housings. These ensure:

- Longer machine lifespan;

- Higher working efficiency;

- Lower maintenance cost.

Machines from reputable manufacturers typically cost more but offer better ROI.

- Additional Features & Customization

- Frequency converter;

- Automatic shot flow adjustment;

- Reinforced wear plates;

- Digital control panel.

These upgrades influence the final quote.

Is a Shot Blasting Machine Worth the Investment?

For most contractors, investing in a shot blasting machine brings significant long-term benefits:

- Lower Labor Cost: One machine can replace 3–5 workers using manual grinders.

- Higher Efficiency: Blasting is 5–10 times faster than traditional surface grinding.

- Better Surface Quality: Creates consistent textures required for epoxy, coatings, and waterproof membranes.

- Reduced Dust & Cleaner Environment: A strong dust collector protects workers and meets environmental regulations.

- Stronger Bonding & Longer Coating Life: Improved surface adhesion reduces coating failures and costly repairs.

For companies considering shot blast equipment for sale, the market offers a wide range of models for different projects and budgets. The key is to choose equipment that matches your typical job size, flooring type, and blasting depth requirements.

How to Choose the Best Shot Blaster for Sale?

When selecting a shot blaster for sale, consider the following:

- Your typical project size (small rooms vs. industrial plants vs. highways);

- Required blasting depth and profile;

- Power availability (380V industrial vs. generator use);

- Terrain and mobility requirements;

- Maintenance and spare parts availability.

A reliable supplier should provide clear parameters, operational guidance, and after-sales support. After comparing various options, several Thai customers ultimately chose our road shot blasting machine. They gave very positive feedback after using it and continue to make purchases.

Best Shot Blasting Machine Price for Your Needs

The shot blasting machine price depends on several factors including width, power, dust collection capacity, and build quality. Whether you need a compact concrete floor bead blaster or heavy-duty shot blast equipment for sale, choosing the right model ensures smoother surfaces, higher efficiency, and long-term cost savings.

A well-selected machine is not just a purchase—it’s an investment that pays for itself in labor reduction, improved finishing quality, and faster project turnover.