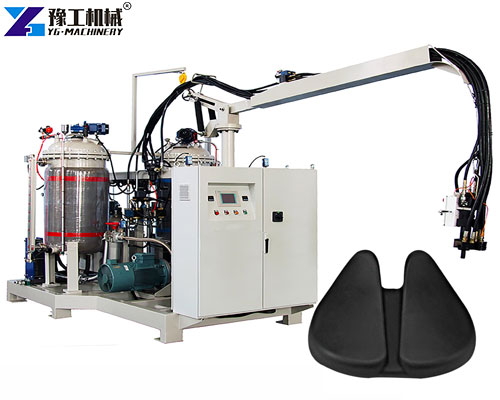

In May 2025, a furniture manufacturer in California purchased a polyurethane foam machine for sale from YG Machinery. The company was looking to improve production efficiency, reduce labor costs, and produce high-quality foam for sofas and mattresses. After careful evaluation of several options, they chose our polyurethane foam machinery for its reliability, automation, and compliance with U.S. safety standards. In addition, YG also produces polyurethane spray machines ideal for roof insulation, tank waterproofing, and other building protection projects.

Polyurethane Foam Machine Parameters

| Item/Model | YG-12 | YG-28 | YG-55 | YG-107 |

| Pouring flow(g/s) | 150-400 | 200-750 | 500-1500 | 1500-3200g |

| Mixing head model | FLT10-14 | FLT10-14 FLT12-18 | FLT12-18 FLT16-25 | FLT16-25 |

| Metering pump model(A2FK, A2VK, A7VK) | 12 | 12-28 | 28-55 | 55-107 |

| Equipment power(380V, 50HZ)(KW) | 21 | 28 | 45 | 78 |

| Flowmeter(optional) | VCG2FCP2 | VCG2FCP2 | VCG2FCP2 | VCG2FCP2 |

| Gas source | 0.6mpa(Nitrogen best) | |||

| Injection time accuracy | 0.1s-99.99s | A: B injection ratio | 1.3-3.1 | |

| Raw material injection pressure | 8-15mps | Injection repeat accuracy | ≤1% | |

| Temperature control accuracy | ±2° | Working pressure of hydraulic station | 12-20mpa | |

U.S. Market Demand for Polyurethane Foam Machines

The demand for polyurethane foam in the U.S. is growing steadily, driven by industries such as furniture, automotive, packaging, and construction. Manufacturers are seeking equipment that can produce consistent, high-quality foam while reducing material waste. Our polyurethane machine meets these needs by offering precise formulation control, high efficiency, and environmentally friendly operation.

Features and Advantages of the Machine

The pu foam machine delivered to the U.S. client included several features that made it stand out:

- High Production Efficiency: Capable of producing large volumes of foam per hour, reducing production time by 30% compared to traditional methods.

- Automated Operation: Fully automated mixing and pouring system ensures consistent density and quality.

- Energy Saving and Eco-Friendly: Optimized for low energy consumption and minimal waste, compliant with U.S. environmental regulations.

- Easy Maintenance: Designed for quick cleaning and easy replacement of wear parts.

- Versatility: Suitable for producing foam for furniture, automotive interiors, packaging materials, and construction insulation.

Real-World Application

At the California furniture factory, the polyurethane foam machine for sale has been used for sofa cushions, mattress cores, and upholstered chairs. By using our polyurethane foam machinery, the factory improved product consistency and reduced foam waste by 15%.

Customer Benefits

- Faster Production: Increased foam output by 30%, enabling faster order fulfillment.

- Cost Savings: Reduced labor and raw material costs due to precise control and automation.

- High-Quality Foam: Improved density uniformity and surface smoothness for end products.

- Reliable After-Sales Support: YG provided installation, operator training, and ongoing technical support.

FAQ about Polyurethane Machine

Q1: What is the production capacity of the polyurethane foam machine?

A1: The machine can produce up to 500 liters of foam per hour, depending on the formulation.

Q2: Can the machine handle custom foam formulations?

A2: Yes, the polyurethane machine allows precise adjustments to suit various foam types.

Q3: Is it compliant with U.S. safety and environmental standards?

A3: Absolutely. Our pu foam machine meets OSHA and EPA requirements.

Q4: What maintenance is required?

A4: Routine cleaning, inspection of pumps and mixers, and replacement of wear parts as needed.

Q5: Is training provided for operators?

A5: Yes, YG Machinery provides on-site training and technical guidance.

PU Foam Machine in YG Machinery?

YG Machinery has a strong track record of supplying high-quality polyurethane foam machinery to customers worldwide, including the U.S. Our machines are designed for efficiency, durability, and safety. With full after-sales support and customization options, we ensure that clients get the most value from their investment. Contact YG Machinery today to discuss your requirements and get a tailored solution for your business.