In 2025, a scrap recycling company in New South Wales purchased a YG excavator magnet for scrap steel handling and site cleanup. Previously, the company relied primarily on manual labor and hand tools to clear steel scrap, resulting in low efficiency and safety hazards.

After introducing the YG hydraulic excavator magnet, operational efficiency saw significant improvements:

- Efficiency Boost: Daily scrap steel handling capacity increased by approximately 50%, substantially reducing cleanup time.

- Ease of Operation: Magnetic force controlled via the excavator’s hydraulic system ensures simple operation and rapid response.

- Equipment Stability: Continuous operation for over 6 months without failure, demonstrating safety and reliability.

Customer Feedback: “The YG excavator magnet attachment not only boosts productivity but also ensures operational safety. It’s one of our most worthwhile investments.”

Excavator Magnet Parameters

| Parameter | STP1200 | STP1200T | STP1300 | STP1300T |

| Weight (kg) | 1750 | 1850 | 1900 | 2050 |

| Dimensions (mm) | 1200*1200*1150 | 1400*1200*1150 | 1300*1300*1150 | 1500*1300*1150 |

| Magnetic Force (gs) | 6000 (8000) | 6000 (8000) | 8000 (10000) | 8000 (10000) |

| Working Pressure (Mpa) | 200 | 200 | 200 | 200 |

| Flow Rate (L/min) | 60 | 60 | 100 | 100 |

| Power (W) | 15000 | 15000 | 20000 | 20000 |

| Voltage (V) | 100-500 | 100-500 | 100-500 | 100-500 |

| Excavator Weight (T) | 18-25 | 20-30 | 25-35 | 25-35 |

Current Market Demand in Australia

Demand for excavator magnets continues to grow in Australia, particularly in NSW and industrial hubs:

- Scrap Recycling & Demolition: High demand for handling steel, scrap machinery, and construction debris.

- Construction Sites: Magnetic cleanup tools rapidly capture and transport metal debris, enhancing site safety.

- Ports & Logistics: Efficient loading/unloading of steel cargo and heavy metal components.

- Track Excavator Operations: Compatible with trackhoes for handling large metal parts.

Key Australian Customer Priorities: High-efficiency, safety-focused, durable hydraulic-powered magnets for sale that integrate with excavators and track machinery (trackhoes), reducing labor costs.

YG Excavator Magnet Solutions

YG offers a full range of excavator magnet attachments and hydraulic excavator magnets to meet diverse industrial needs:

- High magnetic attraction: Powerful magnetism handles steel materials of various sizes and weights.

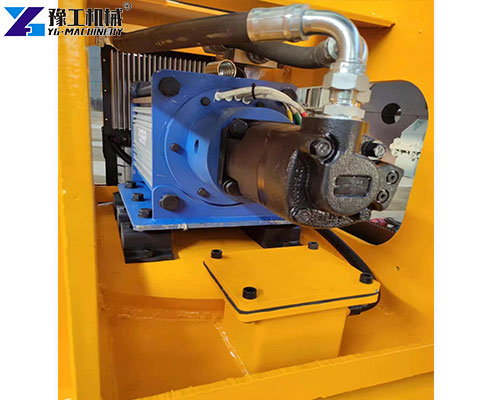

- Hydraulic control: Utilizes the excavator’s hydraulic system without additional power sources for flexible operation.

- Durable design: Constructed from high-strength steel plates with anti-corrosion treatment for harsh environments.

- Multiple Specifications: Customizable sizes and power ratings based on excavator model and magnetic force requirements.

- Quick Installation: Standardized interfaces enable rapid attachment to various excavators, minimizing downtime.

Australia Customer FAQ

Q1: Which excavator models is it compatible with?

A: Suitable for medium to large excavators and tracked machinery. Installation interfaces can be customized for customer equipment.

Q2: What weight range of materials can it handle?

A: Depending on the model, it can lift steel materials weighing 500–5000 kg.

Question 3: Is operation complicated?

Answer: Directly controlled via the excavator’s hydraulic system without external power, ensuring simple operation.

Question 4: Suitable for harsh outdoor environments?

Answer: Constructed with corrosion-resistant treatment and high-strength steel plates, withstanding rain, dust, and high temperatures.

Question 5: Are maintenance costs high?

Answer: Key components are durable, daily inspections are straightforward, and maintenance intervals are extended.

Question 6: How to obtain a quote or request customization?

Answer: Click “Request Quote Now” on the page or contact us via email/WhatsApp for tailored solutions.

Maintenance and Care Guidelines

- Hydraulic System Inspection: Regularly check for leaks or loose connections in piping to maintain stable pressure.

- Magnet Surface Cleaning: Remove metal debris from magnet surfaces to prevent magnetic strength reduction or scratches.

- Fastener Inspection: Ensure bolts and connectors are secure to prevent loosening.

- Anti-Corrosion Treatment: Apply rust-preventive oil in humid environments to extend service life.

- Operational Precautions: Turn off magnet power promptly when unloaded to avoid unnecessary wear or safety risks.

- Regular Maintenance: Conduct comprehensive inspections every 3-6 months, covering hydraulic, magnetic, and structural components.

Excavator Magnet in YG Machinery

YG excavator magnets and hydraulic excavator magnets provide efficient, safe, and durable magnetic handling solutions for industrial, construction, and waste recycling clients across NSW, Australia. Whether you need excavator magnet attachments or hydraulic-powered magnets for sale in NSW, we deliver customized high-performance products that enhance productivity and operational safety.