In recent years, the United Arab Emirates has seen a surge in infrastructure upgrades and urban redevelopment. Cities like Dubai, Abu Dhabi, and Sharjah are demolishing outdated buildings to make room for new commercial and residential projects. This growing need for high-efficiency demolition tools has driven strong demand for the concrete shear excavator.

Traditional demolition methods using hammers or manual cutters have proven too slow, noisy, and imprecise for modern construction standards. Contractors in the UAE are now seeking hydraulic shears for excavator systems that can cut through reinforced concrete and steel structures with speed, safety, and reduced noise—especially in densely populated areas.

Concrete Shear Excavator Parameters

| Product | Excavator-mounted hydraulic demolition shear | ||||

| Item | YG-620 | YG-1413 | YG-2200 | YG-2977 | YG-4052 |

| Weight kg | 620 | 1413 | 2200 | 2977 | 4052 |

| Max. Open Size mm | 334.4 | 540 | 500 | 660 | 801 |

| Width mm | 864 | 1175 | 1370 | 1600 | 1700 |

| Height mm | 1521 | 2050 | 2380 | 2600 | 2700 |

| Effective Shear Depth mm | 286 | 348 | 486 | 578 | 736 |

| Rotating Way | 360 collision | 360 hydraulic | |||

| Working Pressure Bar | 235 | 300 | 320 | 320 | 320 |

| Bottom Shear Force T | 81.2 | 138.2 | 171.2 | 330.2 | 387.2 |

| Medium Shear Force T | 50.2 | 80.2 | 100.2 | 189.2 | 218.2 |

| Tip Shear Force T | 32.2 | 53.2 | 75.2 | 127.2 | 147.2 |

| Applied Excavator Weight T | 5-9 | 10-19 | 20-25 | 28-35 | 38-50 |

Customer Challenges Before Choosing YG Machinery

A demolition company based in Dubai Industrial City approached YG Machinery in 2024. The client was facing several major challenges:

- Low efficiency: Their existing breakers took 4–5 hours to dismantle a single reinforced concrete beam.

- Excessive noise and vibration: The local government imposed noise restrictions in urban demolition areas, limiting work hours.

- High tool wear: Frequent replacement of chisels and breaker components increased operation costs.

- Difficulties cutting steel reinforcement: Their tools could not cleanly separate rebar from concrete, slowing recycling operations.

They needed a powerful concrete shear excavator attachment that could deliver precision cutting, lower noise, and minimal maintenance — all within a reasonable budget.

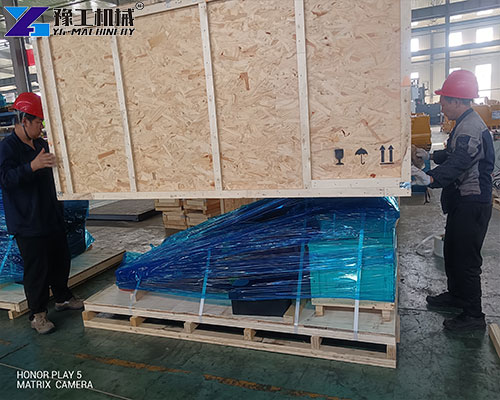

YG Machinery’s Customized Solution

After detailed technical consultation, YG Machinery recommended the YG-CS350 Hydraulic Concrete Shear, part of YG’s heavy-duty demolition shears lineup.

The model was chosen based on the client’s 30-ton excavator and project requirements.

Why YG Concrete Shear Excavator Outperformed Others?

- High Cutting Force with Dual Hydraulic Cylinders

The YG shear generates up to 320 tons of cutting force, efficiently slicing through concrete slabs and 25mm steel rebar in a single stroke. - 360° Hydraulic Rotation

Full rotation allows precise control during structure dismantling, improving safety and reducing repositioning time by 40%. - Replaceable Hardox Blades

Blades are made from Swedish Hardox 500 steel, extending service life by 2–3 times compared to standard alloys. - Noise and Vibration Reduction

The shear’s hydraulic system delivers smooth pressure control, significantly reducing environmental impact—ideal for urban UAE job sites. - Quick Coupler Compatibility

Easily connects to major excavator brands (CAT, Komatsu, Volvo, Doosan), enabling flexible fleet use.

UAE Project Results

After installing the YG-CS350 on their CAT 330 excavator, the Dubai demolition team completed their first project—a multi-story parking structure demolition—in 40% less time compared to their previous method.

The concrete shear excavator not only improved efficiency but also allowed clean separation of steel bars, enabling faster recycling and higher resale value of scrap metal.

“YG’s hydraulic shears for excavator worked flawlessly under Dubai’s extreme heat. The rotation and cutting precision exceeded our expectations, and we’ve reduced our fuel and tool costs by nearly 25%.”

— Mr. Khalid, Project Manager, Dubai Demolition Co.

Customer Benefits Summary of Excavator Shear

Benefit Result:

- Cutting Speed +40% faster demolition;

- Maintenance Cost –30% reduced downtime;

- Noise & Vibration Significantly lower, meets Dubai noise regulations;

- Material Recovery Clean rebar separation, higher recycling revenue;

- Durability Long blade life (Hardox material).

FAQ about Concrete Shear Excavator

Q1: What size excavator do I need for a YG concrete shear?

A: YG offers models for 8–45 ton excavators. The YG-CS200 suits smaller excavators, while YG-CS400 handles large demolition jobs.

Q2: Can the concrete shear excavator cut steel reinforcement bars?

A: Yes. Each YG hydraulic shear features dual cutting jaws that handle reinforced concrete and embedded rebar up to 28mm diameter.

Q3: How does it compare to a hydraulic breaker?

A: Unlike breakers, demolition shears cut rather than impact. This means less noise, faster precision cuts, and reduced stress on excavator arms.

Q4: Is maintenance complicated?

A: No. The shear uses modular blades and hydraulic cylinders, making replacement and inspection simple. Regular greasing ensures long-term reliability.

Q5: Do you provide after-sales support to the UAE?

A: Absolutely. YG Machinery offers remote installation guidance, spare parts supply, and 24-hour online technical service for all Middle East customers.

Why Choose YG Machinery?

- Over 20 years of experience in hydraulic attachment manufacturing;

- Exported to 60+ countries including the UAE, Saudi Arabia, and Qatar;

- Factory-direct pricing and OEM/ODM customization;

- Reliable operation in desert climates;

- Comprehensive after-sales and technical support.

YG Machinery specializes in the production of excavators and excavator attachments. Our popular products include pile breakers, excavator cutters, drillers, high-frequency pile drivers, hydraulic shears, and scrap grabs, etc. Contact us now for more details! [WhatsApp/WeChat/Phone] +86 13837115193.