In February 2025, a construction material supplier from St. Vincent contacted YG Machinery after watching a YouTube video demonstration of our fully automatic brick machine. The customer, Marcus, who runs a mid-sized construction firm focused on affordable housing projects in Kingstown, reported growing frustration with inconsistent manual labor and rising concrete block costs. He was particularly interested in automation and asked us directly about the automatic brick making machine price. After reviewing several options, he confirmed that cost-efficiency, durability, and ease of use were key factors for his company

Marcus had initially used a small concrete brick making machine, but production volume and brick uniformity could no longer meet the demands of his expanding contracts. Upon delivery and installation of the new machine, he confirmed that switching to automation significantly improved his project timelines and reduced overall brick production costs by over 20%.

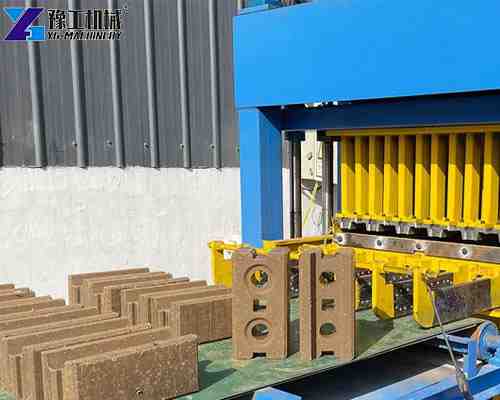

Specifications of YG Automatic Brick Making Machine

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Addressing the Demand for Affordable, Durable Bricks in St. Vincent

Like many island nations, St. Vincent faces several logistical challenges in importing building materials. The costs are high, and the availability is inconsistent. Local contractors, including Marcus’s team, often experience project delays due to material shortages. The limited supply of skilled labor further drives up construction costs, especially in the housing sector.

Marcus’s company was developing low-cost, hurricane-resistant housing for rural communities. His primary challenge was producing consistent, structurally sound bricks on-site, without relying on expensive imports. He needed a solution that could run efficiently with minimal oversight and use readily available local materials.

By consulting with our technical team, Marcus learned that the automatic brick making machine price was competitive not only in initial cost but also in its long-term savings. Unlike his older manual system, this unit could run for 8–10 hours daily with just two operators, drastically cutting labor costs. Local aggregates and cement were enough to produce high-strength bricks suitable for structural walls.

Why the Automatic Brick Making Machine Was the Right Solution?

The automatic brick making machine addressed multiple pain points for our customer:

- Reduced Labor Dependency: The machine’s full automation meant fewer workers were needed, resolving a major bottleneck during peak construction months.

- Consistent Brick Quality: With PLC-controlled pressure and vibration settings, the machine produced uniform, high-strength bricks with minimal rejection rates.

- On-site Production Flexibility: Marcus could shift between hollow and solid blocks without significant downtime—especially useful for different building phases.

- Faster Project Turnarounds: Daily output increased by more than 60%, enabling Marcus’s company to meet deadlines even during labor shortages.

- Cost Efficiency Over Time: The automatic brick making machine price was recouped within the first 8 months through savings on labor, materials, and third-party suppliers.

Application Scenarios: From Homes to Infrastructure

This machine isn’t limited to house construction. In Marcus’s case, it was used in:

- Affordable housing for displaced families after tropical storms.

- Boundary wall projects for agricultural land development.

- Paving projects for access roads in remote areas.

- Schools and clinics constructed by local government contracts.

Another benefit mentioned in customer feedback was its compatibility with local volcanic ash and river sand—a huge plus in island contexts where traditional clay is scarce. One of Marcus’s subcontractors noted, “It’s like having an extra ten workers who never get tired. The auto bricks machine did in one week what used to take three.”

Advantages That Make the Difference

Here are several reasons our equipment stands out in the Caribbean region:

- Thermal Efficiency: Bricks produced retain internal temperature, ideal for tropical climates.

- Noise & Vibration Control: Designed for urban areas without disturbing nearby residents.

- Low Maintenance: Hydraulic components are imported and tested for 3 years of non-stop use.

- Scalable Production: Suits both small community builders and government-backed infrastructure firms.

Compared to a basic automatic brick machine from other sources, our solution comes with comprehensive installation guidance, a year-long warranty, and lifetime technical support.

Classification of brick making machines

- According to the molding principle: pneumatic brick machine, vibrating brick machine, hydraulic brick machine, etc.

- According to the degree of automation: automatic brick machine, semi-automatic brick machine and manual brick machine.

- According to the output: large brick machine, medium brick machine and small brick machine.

- According to sintering or not: sintering brick machine and baking-free brick machine.

- By use: cement brick making machine, fly ash brick making machine, clay brick making machine, etc.

Why Choose YG Machinery?

YG Machinery has supplied automated construction solutions to over 35 countries, including in the Caribbean, South America, Southeast Asia, and Africa. We tailor each system to match real-world project needs, and we never just sell a product—we provide a solution.

Our manufacturing team ensures that each unit undergoes strict testing before shipment. Spare parts and training videos are provided with every unit, making it easier for new users to operate and maintain. If you are searching for the best automatic brick making machine price with real-world value, YG is your trusted choice.

Related Equipment You May Like: concrete block making machine, fly ash brick making machine, cement brick manufacturing machine, concrete mixer machine with pump, etc. Contact us today for a free quote.【WhatsApp/WeChat/Phone/Skype】+86 13837115193.