In August 2024, Peter, the head of an emerging environmental packaging company from Nairobi, Kenya, contacted YG to inquire about cup making machine price. Due to the strengthening of local environmental regulations, paper packaging instead of plastic products has become a trend, Peter urgently needs a stable, efficient, easy to operate cup maker machine, for the production of a variety of specifications of paper cups, including the common paper tea cup making machine required size.

After the video conference, the customer clearly indicated that he had high requirements for the machine’s molding accuracy, production speed, operational safety and the convenience of mold replacement at a later stage. He also mentioned that he hoped to purchase cost-effective equipment under the premise of controlling the budget, so he was very concerned about the core factor of cup making machine price.

Cup Making Machine Parameters

| Model | YG-800 | YG-C800 | YG-S800 | |

| Paper Cup Size | 3-16OZ | 3-16OZ | 3-16OZ | |

| Raw Material | One-side PE | One-side PE | One-side or two-side PE-coated paper (Singe PE or Double PE coated paper) | |

| Speed | 65-75 pcs/min | 70-80 pcs/min | 75-85 pcs/min | |

| Suitable paper weight | 150-180g;±20g | 150-300g;±20g | 160-300g/;±20g | |

| Voltage supply | 380V, 50HZ | 380V, 50HZ | 380V(220V) 50HZ | |

| cup size | Bottom35-70mm, Top45-90mm High32-135mm | Bottom35-70mm,Top45-90mm, High32-135mm | Bottom35-70mm, Top45-90mm, High32-135mm | |

| General power | 4.5 kW | 5 kW | 6 kW | |

| Working Air Source | NO | NO | 0.4-0.6Mpa; 0.4m3/min | |

| Net weight | 1680kg | 1680kg | 2000kg | |

| Measurement (mm) | L:2115mm;W:1000mm;H:1700mm | L:2115mm;W:1000mm;H:1700mm | Main engine | L:2100mm;W:1200mm;H:1800mm |

| Cup holder | L:900mm;W:600mm;H:1500mm | |||

| Cup Side Sealing | Copper bar heating | Evergreen Ultrasonic | Evergreen Ultrasonic | |

| Bottom Knurling | Heating | Heating | Hot Air System | |

| We can customize the machine and mold according to the customer’s requirements. Also, we have a high-speed machine, 100-150pcs/min. | ||||

Kenya Market Status and Customer Pain Points

In Kenya, the use of paper cups is climbing year by year, especially in the field of fast consumption such as catering, coffee, tea and so on. However, the local cup maker machine generally has low automation, high failure rate, high energy consumption and other problems, it is difficult to meet the needs of mass production. peter before the use of domestic equipment often due to the seal is not secure or the bottom of the cup leakage led to the return of the cup, which seriously affects the brand reputation.

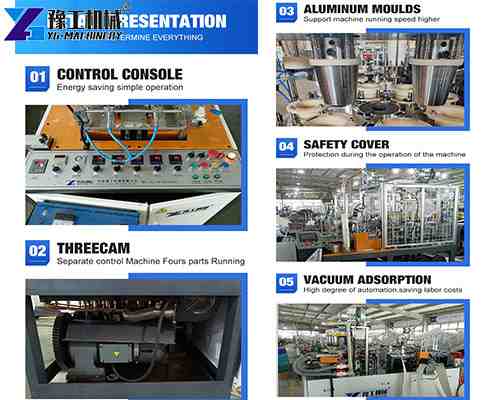

Understanding these problems, we suggested him to choose YG’s paper cup forming machine, which not only has mature technology and low failure rate, but also adopts imported parts to ensure the continuous operation of the machine. At the same time, the price is transparent and reasonable, fully considering the customer’s concern about cup making machine price.

At the same time, we are equipped with an easy-to-change mold system according to customers’ needs, which can realize the production of different paper cup sizes, ensuring that one machine meets multiple needs and reduces the overall investment cost.

YG Solution and Practical Application

YG team customized a complete production solution for the customer: a YG-C800 cup maker machine, equipped with multiple sets of molds, supplemented with paper raw material suggestions and installation and commissioning guidance. Upon arrival, the machine only needs to be connected to the power supply and gas source, and can be started up smoothly according to the operation video and manual, without the need for complicated secondary installation.

Customer feedback shows that the machine performs stably in actual production, and the finished paper cups are smooth and well sealed, which meets the local market’s high standard requirements for paper tea cup making machine.Peter especially mentioned that the machine is quick to change the molds and easy to operate, which greatly reduces the dependence on manual labor and improves the production efficiency.

Product Advantages and Applicable Scenarios

The equipment is suitable for cafes, milk tea stores, take-away catering packaging enterprises, especially for small and medium-sized enterprises (SMEs) with diversified demands and sensitivity to production cost and cup making machine price. The integrated design of automatic feeding, cup molding, heating, bottom sealing and cup collecting, safe operation, low energy consumption, and adaptable to long time high load operation, especially suitable for Kenya and other emerging markets.

Cup Making Machine Price in YG

YG as a professional paper cup machine supplier has 18 years of experience in the industry, the products are exported to Europe, America, Africa and the Middle East, and the quality and service have been praised by customers. Each machine enjoys one year warranty and lifetime technical support, completely solving customers’ worries. YG also offer: paper bowl making machine, fully automatic paper cup machine, low price paper cup machine, etc. Contact us to know more details now! WhatsApp/Phone/Skype】+86 13837115193.