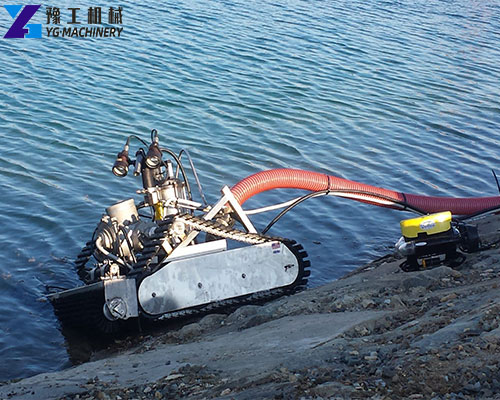

Recently, a Polish water environment management company purchased an intelligent dredging robot to remove long-accumulated silt from a city park lake. Due to the large lake area, viscous silt layer, and uneven water depth, manual labor and traditional machinery were not safe and efficient enough for the client. Therefore, the client needed equipment that could operate stably in complex water conditions.

YG equipped the robot with a visual monitoring system, a remote control console, and a tracked underwater chassis, making the entire dredging process more precise, safer, and more controllable. After the equipment arrived in Poland and was put into use, the client reported high efficiency, ease of operation, and convenient maintenance, far exceeding expectations.

This success story further enhances the brand awareness of YG’s intelligent dredging robot in the European market.

Intelligent Dredging Robot Parameters

| Parameter | YG500 | YG600 | YG700 | YG800 | YG900 | YG1200 |

| Robot Dimensions (mm) | 1500*500*650 | 1500*600*650 | 1600*700*650 | 1600*850*700 | 1650*960*750 | 1900*1200*750 |

| Dredging Width (mm) | 500 | 600 | 700 | 800 | 900 | Suitable for large culverts |

| Travel Speed (m/s) | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 0–17 m/min |

| Pump Diameter (inch) | 3 | 3 | 4 | 4 | 4 | 4or6 |

| Pump Flow (m³/h) | 100 | 100 | 160 | 160 | 200 | 250 |

| Pump Head (m) | 0–30 | 0–30 | 0–25 | 0–25 | 0–25 | 0–30 (Horizontal: 100–150m) |

| Hydraulic Station Dimensions (mm) | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2200*1200*1700 | 2120*1240*1200 |

| Main Motor Power (kW) | 18 | 18 | 22 | 22 | 22 | 45KW (50KW) or Diesel 76KW (123KW) |

| Hydraulic System Pressure (Mpa) | 0–16 | 0–16 | 0–16 | 0–16 | 0–16 | Not specified |

| Particle Size (mm) | 15 | 15 | 40 | 40 | 50 | 0–40 (customizable) |

| Winch Speed (r/min) | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 | 0–10 |

| Pipe Length (m) | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30–50 Optional | 30m/pack, 20kg pressure resistant, optional |

| Control System | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote |

| Lighting System | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 | Underwater LED*2 |

Common Needs in the Polish Market: These Pain Points Resonate More with Users

Customers from Poland and neighboring countries generally reported the following pain points, which highly align with the application scenarios of this project:

1: Long-term sediment accumulation in lakes prevents traditional equipment from accessing the site.

Many urban lakes, wetlands, and scenic water areas suffer from deep sediment buildup. Manual cleaning is extremely inefficient, while large dredgers cannot access narrow or shallow water areas.

→ The miniaturized intelligent dredging robot with a tracked chassis perfectly solves the access problem.

2: High Risk in Enclosed Environments such as Chemical Plants and Sedimentation Tanks.

Local factories in Poland often need to clean sediment, but enclosed spaces contain gases, and the sludge is corrosive and viscous, making manual access dangerous.

→ The remote control dredging robot’s remote operation eliminates these safety risks.

3: Large volumes of sludge cannot be transported or discharged in a timely manner.

Many companies experience sludge accumulation after dredging, leading to secondary pollution.

→ YG’s sludge transport robot and high-lift mud pump transport sludge to the onshore dewatering system.

YG’s Professional Solutions for Polish Clients

Based on the specific working conditions of the Polish client, YG customized the equipment as follows:

- Visual Monitoring System: Real-time monitoring of underwater conditions, mud layer thickness, and equipment posture improves construction accuracy and safety.

- Remote Operating System (remote control dredging robot function): Operating distance up to 300–500 meters, eliminating the need for personnel to enter the water.

- Crawler-type Underwater Walking Structure: Adapts to complex terrains such as muddy bottoms, soft soil, and silt layers, preventing slippage and sinking.

- High-Flow Mud System (sludge transport robot function): Supports continuous transport to the onshore dewatering machine or sedimentation tank.

- Optional Explosion-Proof Motor (Suitable for Chemical Plant Scenarios): For customers using the robot in chemical plants, oil tanks, or hazardous environments, an explosion-proof system can be added to further enhance safety.

YG’s intelligent dredging robot is not only suitable for lake remediation in Poland but also widely used in various applications such as chemical plant pool bottom cleaning, river maintenance, and wetland restoration. In addition, the dredging robots have received very positive feedback in African countries such as South Africa.

Why do European customers continue to choose YG Intelligent Dredging Robot?

① Highly Adaptable Underwater Robot Design

More flexible than traditional dredgers, it can operate in narrow waters, shallow water areas, and within factory pools.

② Truly Fully Controllable and Visualized Operation

Reduces errors, rework, and safety hazards.

③ Easy to Transport, Deploy, and Operable by a Single Person

Ideally suitable for remediation projects and engineering companies that require frequent relocation.

④ High Return on Investment (ROI)

Customers generally report that the cost can be recovered within 6–12 months after purchase, and long-term operating costs are far lower than labor or leasing large vessel-type equipment.

FAQ from Polish Customers

Q1: What are the water depth requirements? How deep can the equipment operate in lakes?

A: Standard models are suitable for depths of 0.5–6 meters; deeper depths can be customized.

Q2: Can it be used in chemical plants or corrosive environments?

A: Yes, and options include explosion-proof motors, corrosion-resistant pump bodies, and sealed wiring systems.

Q3: Is operation by specialized technicians required?

A: No. Users can complete basic operation training within 1–2 hours.

Q4: Is maintenance complex?

A: Maintenance points are minimal, mainly involving pump body inspection, track system lubrication, and wiring checks.

Q5: Is it a worthwhile investment?

A: For companies requiring long-term lake management, sedimentation tank cleaning, or industrial sludge treatment, purchasing an intelligent dredging robot is more cost-effective and efficient than leasing or outsourcing, making it a long-term return on investment.

Intelligent Dredging Robot in YG Machinery

YG’s dredging robots have been exported to Europe, Africa, Australia, and other regions in recent years, demonstrating stable and efficient performance in various applications such as lake cleaning, environmental remediation, chemical plant scale removal, and oil tank cleaning, consistently earning genuine praise from customers. Many existing customers have placed repeat orders after their initial use, fully demonstrating the product’s reliability and investment value. If you would like to learn more about the technical details or obtain project solutions, please contact the YG expert team immediately.【WhatsApp/WeChat/Phone】+86 13837115193.