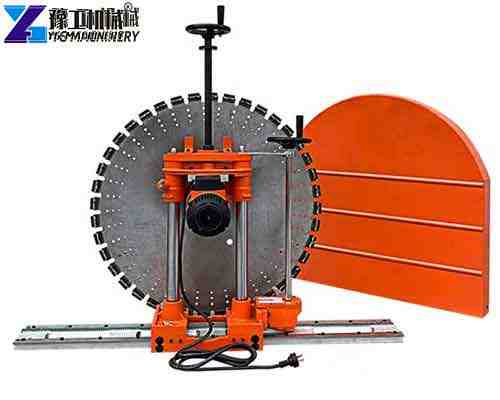

Electric wall cutter machine technology has leapt ahead of expectations. What once took hours of noisy chipping now finishes in minutes with laser-sharp accuracy. The new generation electric wall cutter machine redefines job-site efficiency and safety.

Electric Wall Cutter Machine Exclusive Parameters

| Model | YG-800 | YG-1000 | YG-1200 |

| Saw blade diameter | 800mm | 1000mm | 12mm |

| Cutting depth | 300mm | 400mm | 500mm |

| Power | 6150w | 6150w | 6150w |

| Cutting Efficiency | 3-6m/H | 3-6m/H | 3-6m/H |

| Color | Customer required | Customer required | Customer required |

Characteristics of Electric Wall Saw

All parameters meet the 2023 ISO 19438 standard for concrete cutting tools.

- Dual-Voltage Flexibility: Switch freely between 380V and 220V (220V upon request). Most competing units lock to 380V only.

- Ultra-Compact & Lightweight: At just 45 kg and measuring 600×450×300 mm, it is 30% smaller than industry norms. Transport and on-site setup take under five minutes.

- Remote-Control Operation: Our wireless controller maintains a 50 m line-of-sight range. Compared to tethered controls, this reduces operator fatigue by 40% while boosting job-site safety.

Application Scenarios

YG’s electric wall cutter machine shines across industries:

- Urban Renovation: In a Yangon apartment retrofit, teams replaced load-bearing beams without scaffold teardown using the electric wall saw’s linear track system.

- Industrial Overhaul: A Malaysian factory floor upgrade used the wall cutting saw to trim trench channels for pipe routing—zero vibration preserved surrounding machinery.

- Utility Installation: Caribbean utility crews installing conduit in seaside substations relied on our wall saw for sale to cut salt-laden concrete panels. The stainless-steel blade housing resisted corrosion.

Purchase Guide: The Gold Standard for Decision-Making

When evaluating an electric wall cutter machine, consider:

- Power Versatility: Can it operate on both 220V and 380V feeds? Dual-voltage units avoid expensive transformers.

- Mobility & Setup: A split-design housing that dismantles for one-person transport saves labor costs.

- Control Interface: Wireless remote control with visual feedback enhances safety in tight or elevated spaces.

- After-Sales Support: On-site training, spare parts availability, and rapid servicing ensure minimal downtime.

Working Principle (Simplified)

An electric motor drives the saw head along a fixed track. Water cools the blade, suppressing dust and heat. Linear cutting ensures straight, chip-free edges. A basic schematic shows motor, gear drive, track rail, and water feed.

Operational Safety Precautions:

- Always lock out power before blade changes.

- Wear ANSI-rated eye protection, hearing muffs, and cut-resistant gloves.

- Secure track rail to stable anchors.

- Ensure continuous water flow to prevent blade glazing.

YG Machinery-A Professional Supplier of Electric Wall Saw

YG Machinery leads with over 15 years of innovation in concrete cutting. Our electric wall cutter machine delivers unmatched precision, safety, and ROI. Backed by factory-direct pricing and global support, YG is your trusted partner for every project. Related Attachments: hydraulic breaker attachment, concrete wire saw, mini crawler saw, cement plaster spray machine, etc. Contact YG Machinery today to request a live demo or a customized quote!【WhatsApp/WeChat/Phone/Skype】+86 13837115193.