In modern engineering construction, in order to ensure the flatness and construction efficiency of concrete flooring, concrete laser leveling machine has become an indispensable key equipment. Whether in industrial plants, warehousing and logistics bases, or in large shopping mall flooring projects, concrete laser leveling machine has shown excellent construction performance and technical advantages.

Multiple Models to Meet Different Construction Needs

YG Machinery offers a wide range of concrete laser leveling equipment, such as YGJX31, YGJX32, YGJX33, YGJX34, etc., with configurations ranging from motor drive to hydraulic control system, and with a construction width of up to 2.5 meters, which is suitable for all kinds of medium- and large-sized construction projects.

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, stepless speed | Handle control, stepless speed | Handle control, stepless speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

If you care about Concrete Laser Leveling Machine Price, Contact us to know more details now![WhatsApp/WeChat/Phone] +86 13837115193.

What is Laser Leveling Machine?

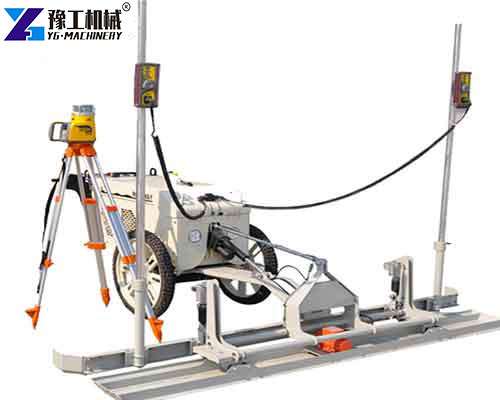

Laser leveling machine is a kind of professional equipment that utilizes laser positioning technology to vibrate, level and level the surface of newly poured concrete. By matching the laser transmitter and receiver, the height position of the leveling head is monitored and adjusted in real time, thus achieving millimeter-level flatness control in large-area construction.

Operation Principle of Concrete Laser Leveling Machine

The equipment is usually equipped with a separate laser transmitter that continuously rotates and creates a laser control plane. The laser receiver on the leveling machine receives the signal and automatically adjusts the leveling head’s height position via a microcomputer control system to ensure that the construction surface is always at the same horizontal reference. The feedback frequency is as high as 10 times/second, which can effectively eliminate human error and ensure that the error is controlled within the range of ±3mm.

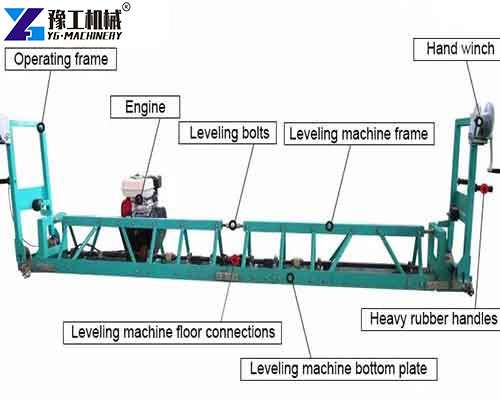

Core Structure Composition of Laser Leveling Machine

The whole machine is mainly composed of two main parts: the main machine and the leveling head. Leveling head includes scraper, vibrator, laser receiver, hydraulic push rod and other components, with laser receiver for sale real-time accurate adjustment. The whole machine can be equipped with optional high-pressure cleaning system to effectively extend the service life of the equipment.

Technical Highlights of Laser Leveling Machine

- High-precision control system: laser + closed-loop control technology, construction error is small, the leveling effect is far more than the traditional manual construction methods.

- Integrated design: hydraulic leveling, vibration and automatic leveling in one, greatly reducing the construction seams and improving the overall strength of concrete.

- Intelligent operating system: multi-language operation interface, key and handle integrated control, simple operation and labor saving.

- Integrated operation: it can be synchronized with reinforcing mesh and construction formwork to improve the overall stability of the floor.

- Cost saving: Compared with traditional construction methods, it significantly reduces labor input and maintenance costs.

Wide Range of Applications

This laser leveler machine from tractor leveler machine manufacturer is suitable for the following scenarios:

- Large-scale industrial floor construction;

- Concrete paving in logistics parks;

- Underground garage construction in shopping malls;

- High-standard factory floor construction;

- Cold storage, warehousing floor leveling construction.

Laser Receiver Introduction

YG provides laser receiver which supports wireless charging, can work continuously for 20 hours after 6-8 hours of charging, and the signal coverage radius is up to 100 meters, which is the key sensing component in the leveling system.

Why Choose YG Laser Leveler?

As a professional ride-on concrete laser screed manufacturer, YG Machinery has many years of experience in leveling equipment production. We not only provide standard models, but also can customize the parameters of the machine according to the needs of the customer’s project, to ensure that each machine can play its best performance on the site.

In addition, we offer a wide range of machines, including grouting machines, road rollers, line marking machines, mini excavators, etc., to build a complete construction solution.