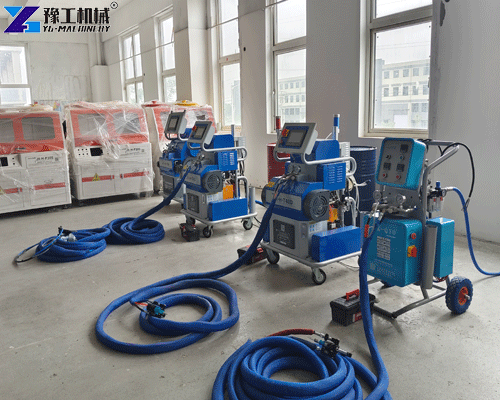

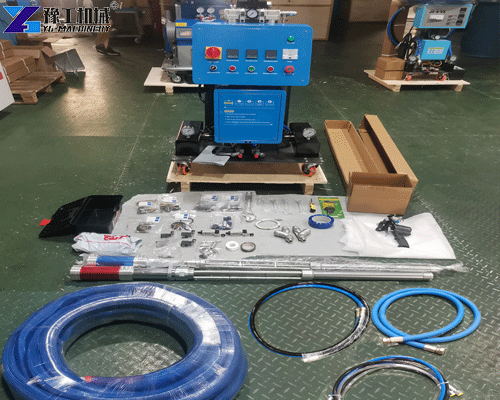

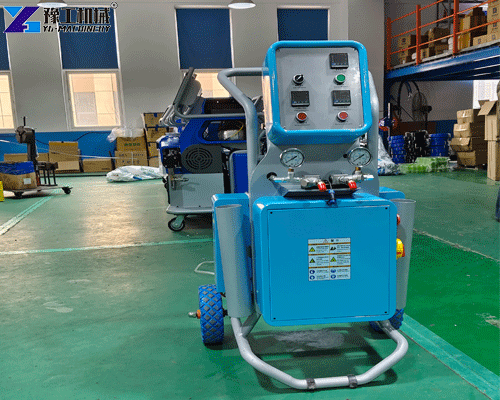

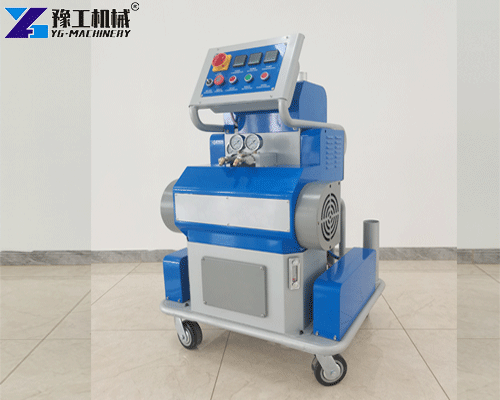

A small polyurethane spray machine is a compact solution designed for on-site insulation and waterproofing projects. It is ideal for roof and wall insulation, renovation work, and applications that require easy transportation and simple operation.

This type of polyurethane spray equipment provides stable heating, accurate material mixing, and consistent spraying performance, helping contractors achieve uniform foam quality while reducing operating and maintenance complexity.

Polyurethane Foam Equipment Parameters

| Model | YG-H-T50 | YG-H5600T | YG-H-T40 | YG-H5600 | YG-Q30 | YG-IIIH |

| Power Supply | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/220V | 380V/220V |

| Heating Power | 25 kW | 25 kW | 22 kW | 22 kW | 15 kW | 9.5 kW |

| Total Power | 29 kW | 29 kW | 26 kW | 26 kW | 15.5 kW | 9.5 kW |

| Drive Type | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Pneumatic | Pneumatic |

| Material Output | 2–8 kg/min | 2–8 kg/min | 2–12 kg/min | 2–12 kg/min | 2–10 kg/min | 2–10 kg/min |

| Air Supply | ≥0.6 m³/min | ≥0.6 m³/min | ≥0.6 m³/min | ≥0.6 m³/min | 0.5–1 MPa ≥1 m³/min | 0.5–0.8 MPa ≥0.9 m³/min |

| Max Output Pressure | 36 MPa | 36 MPa | 36 MPa | 36 MPa | 28 MPa | 25 MPa |

| A/B Ratio | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 |

| Heating Temperature Range | 0–85°C | 0–85°C | 0–85°C | 0–85°C | 0–85°C | 0–80°C |

| Packaging Size (LWH) | 1350×1150×1650 mm | 1350×1150×1650 mm | 1250×1050×1500 mm | 1250×1050×1500 mm | 850×850×1650 mm | 850×850×1650 mm |

| Gross Weight | 420 kg | 420 kg | 350 kg | 350 kg | 200 kg | 205 kg |

| Air Compressor | – | 4 kW, 0.5 m³/min | 4 kW, 0.5 m³/min | – | 7.5 kW, 0.9–1.0 m³/min, 8 bar | – |

AApplications of Small Polyurethane Spray Machines

- Building Insulation

Widely used for on-site insulation of walls, roofs, attics, and container houses, helping reduce heat loss and improve energy efficiency. - Roof Waterproofing and Protection

Suitable for polyurethane spray coating on flat roofs, metal roofs, and repair projects, forming a continuous protective layer. - Pipe and Tank Insulation

Applied to pipelines, storage tanks, and equipment surfaces for thermal insulation and condensation control. - Renovation and Localized Projects

Ideal for renovation work, small-scale insulation jobs, and projects with limited space where compact equipment and easy operation are required.

Case Study: Small Polyurethane Spray Machine for Insulation Project in Mexico

In 2025, a regional contractor in Mexico selected YG’s small polyurethane spray machine for on-site building insulation projects. The contractor previously relied on manual insulation methods and basic spraying equipment, which resulted in uneven foam thickness, low efficiency, and inconsistent insulation performance across different job sites.

After deploying the YG small polyurethane spray machine, the following improvements were achieved:

- Spraying Efficiency

The compact spray system enabled continuous operation and faster application, increasing overall insulation efficiency by approximately 30% compared to previous methods. - Foam Uniformity and Adhesion

Stable heating and accurate material mixing ensured uniform foam density and strong adhesion on walls and roofs, improving thermal performance and surface coverage. - Ease of Operation

The user-friendly control system allowed operators to become proficient within a short training period, reducing reliance on skilled labor. - Mobility and Flexibility

The compact size made transportation between job sites easier, especially for renovation and localized insulation projects. - Customer Feedback

“Since using YG’s small polyurethane spray machine, our insulation work has become more efficient and consistent. The machine performs reliably across different sites, and our project timelines are much easier to control.”

Technical Highlights and Advantages

- Compact and Portable Design

Designed for easy transportation and on-site use, suitable for renovation projects and localized insulation work. - Stable Heating and Accurate Mixing

Ensures consistent material temperature and precise A/B ratio control, delivering uniform foam density during spraying. - Reliable Spraying Performance

Maintains stable pressure output for smooth and continuous spraying with a low failure rate during operation. - Energy-Efficient Operation

Optimized power consumption for small and medium projects, helping reduce operating and maintenance costs. - Wide Application Compatibility

Supports polyurethane spray foam for insulation as well as protective coating applications on walls, roofs, pipes, and tanks.

FAQ: Small Polyurethane Spray Machine

Question 1: What materials can be used with a small polyurethane spray machine?

Answer: The machine is suitable for two-component polyurethane spray foam materials commonly used for building insulation and protective coating applications, including rigid polyurethane insulation foam.

Question 2: Is a small polyurethane spray machine suitable for large projects?

Answer: It is designed mainly for small to medium-sized projects, renovation work, and localized insulation. For large continuous industrial projects, higher-capacity spray systems are recommended.

Question 3: Is the operation of a small polyurethane spray machine complicated?

Answer: No. The machine features a user-friendly control system, allowing operators to become familiar with spraying operation after a short training period.

Question 4: Are maintenance and operating costs high?

Answer: Maintenance requirements are relatively low. With proper cleaning and routine inspection, the machine maintains stable performance and low operating costs.

Question 5: How can I get a price or place an order?

Answer: You can click the “Request a Quote” button on this page or contact us via WhatsApp or email. Our technical team will recommend a suitable configuration based on your project needs.

Polyurethane Foam Equipment in YG Machinery

Inquire about YG polyurethane foam machine today to obtain tailored solutions that enhance production efficiency and foam quality, making your industrial operations more efficient and reliable.