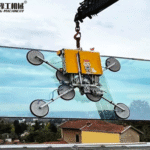

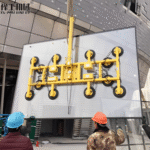

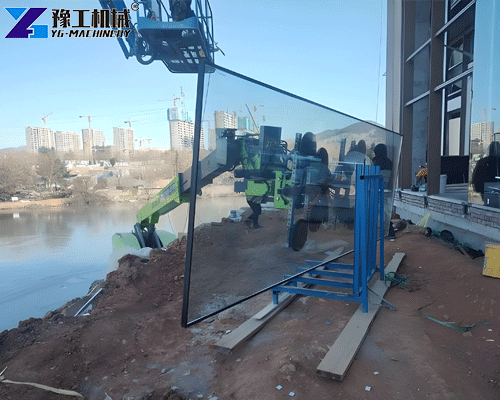

In February 2025, a prominent façade installation contractor based in Houston, Texas, approached YG Machinery with a specific challenge: their team was struggling to install oversized architectural glass panels on a high-rise commercial building. Manual lifting and traditional hoisting methods posed high risks and inefficiencies. After receiving a demonstration of our advanced glass vacuum lifters for sale, the client decided to order two YG600 models. Within weeks, their project timelines improved significantly, and the site’s safety score also increased. “The lifting was precise, and the stability exceeded our expectations,” the project manager commented. This case highlights how modern glass vacuum lifting equipment is transforming construction operations across the United States.

Glass Vacuum Lifting Equipment Specifications

YG Machinery offers a range of models to suit various project demands. Below are the key specifications of our best-selling models:

| Parameter | Unit | 400 | 600 | 800 | 1000 | 1200 |

| Load Capacity | kg | 400 | 600 | 800 | 1000 | 1200 |

| Pads Size | mm | Φ300 | Φ300 | Φ300 | Φ300 | Φ300 |

| Pads Qty | pcs | 4 | 6 | 8 | 10 | 12 |

| Battery | V/Ah | 46376 | 46376 | 46376 | 46376 | 46376 |

| Charger | V/A | 46197 | 46197 | 46197 | 46197 | 46197 |

| Rotation | ° | 360 | 360 | 360 | 360 | 360 |

| Tilting | ° | 90 | 90 | 90 | 90 | 90 |

| Suction Frame Size (X) | mm | 920×820 | 2430×1090 | 1980×1610 | 1980×1610 | 1980×1610 |

| Suction Frame Size (H) | mm | 2396×1180 | 2396×1180 | 2396×1180 | 2396×1180 | 2396×1180 |

| Packing Size (X) | mm | 1200×800×520 | 1200×800×520 | 1200×800×520 | 1200×800×520 | 1200×800×520 |

| Packing Size (H) | mm | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 | 2250×1080×590 |

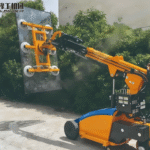

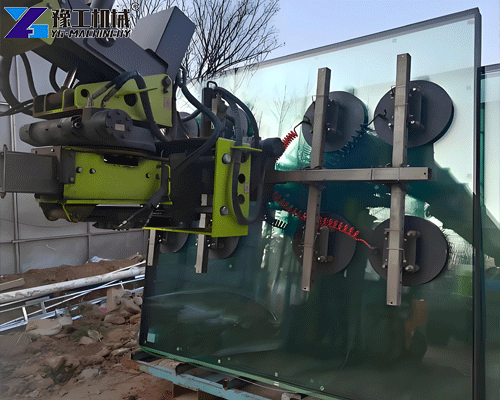

Each model includes automatic lifting, horizontal and vertical motion options, and both electric and manual rotation capabilities. When paired with a telehandler, spider crane, or articulating boom lift, a glass lifter machine enables efficient glass installation.

The Situation in the U.S. Market for Glass Lifter Machine

As modern architecture in the United States shifts toward energy-efficient buildings and full-glass façades, construction companies increasingly face the challenge of safely lifting large and fragile materials. Traditional cranes and manual methods often fall short in terms of safety and accuracy. In colder states like Minnesota or high-wind areas such as Chicago, contractors have expressed concerns about both worker safety and glass integrity during installation. These market conditions are driving the growing demand for glass vacuum lifters for sale in the U.S., especially models with smart safety systems and high load capacities.

How YG’ Glass Vacuum Lifting Equipment Solved U.S. Contractor Pain Points?

The Houston-based contractor mentioned earlier was facing multiple setbacks—glass panels being scratched during installation, delays from waiting on crane availability, and high labor costs. YG’s YG600 model provided a complete solution:

- Reduced Labor: One operator was sufficient to control the lifter remotely, reducing reliance on multiple workers.

- High Safety Standards: Built-in sensors detected any drop in vacuum pressure and triggered automatic shutdown.

- Time Efficiency: Glass panels that previously took 20 minutes to place were now being installed in under 8 minutes.

They noted that the glass lifter machine operated smoothly even in tight spaces, thanks to its flexible support structure and rotating suction arms.

Other Benefits and Versatile Applications

Beyond high-rise construction, the equipment has proven useful in a wide range of scenarios:

- Interior Glass Installations: Ideal for malls, museums, and airports with extensive glass partitioning. The quiet operation of the machine makes it suitable for indoor environments.

- Glass Workshops: Facilitates quick, damage-free movement of glass sheets from cutting stations to storage or assembly lines.

- Solar Panel Handling: Accurate placement of fragile photovoltaic panels in production facilities.

- Automotive Glass Assembly: Frequently used in car manufacturing plants for precise windshield and side glass installation.

One U.S. customer specializing in customized windows praised how the machine allowed their team to install oversized sliding doors safely. “We had used a glass vacuum lifting equipment from another supplier, but YG’s machine felt more stable and intuitive,” the owner remarked.

FAQ about Glass Vacuum Lifter

Q1: What are the main applications for Glass Vacuum Lifter?

A: Our vacuum lifters are widely used in a variety of applications, including high-rise curtain wall installation, large glass curtain walls, interior glass partitions, handling multi-layer glass panels, solar photovoltaic panel installation, and logistics handling in automotive and glass product factories. They are ideal for work environments requiring safe, efficient, and precise handling of fragile panels.

Q2: Are these lifters legal for use in the United States? Do they comply with local safety and certification standards?

A: Yes. Our models offer international certifications such as CE and ISO, and we can provide configurations that meet US or North American market standards (such as UL, OSHA, and ANSI requirements) upon request. We recommend that customers confirm the required certifications or standards at the time of purchase and inform us in advance so we can make appropriate adjustments.

Q3: What is the maximum load capacity of these lifters? Is it achievable in actual construction?

A: Depending on the model, the load capacity typically ranges from 300kg to 800kg (in both retracted and extended positions). Taking the YG600 model as an example, its load capacity in retracted mode is 600kg, and in extended mode it is 300kg. We load-test each device before shipment to ensure stable operation under the designed load.

Q4: How do we ensure that the glass does not get scratched or shattered when using a vacuum lifter?

A: We use high-quality rubber suction cups with excellent anti-slip and cushioning properties.

The number, size, and layout of the suction cups can be customized to suit the glass sheet size, ensuring uniform force distribution.

The device is equipped with a vacuum monitoring sensor that automatically alarms or shuts down if the vacuum level drops.

It is recommended to use protective film, cushioning, or anti-scratch material on fragile glass, especially during the installation and docking phases.

Q5: What is the delivery, transportation, and installation support for the device in the United States?

A: We provide door-to-door transportation from our China factory to the United States (including ocean freight and container shipping) and assist with export and import customs clearance. Upon arrival at the US port of destination, we can also arrange for our technicians or partners to provide installation guidance, commissioning, and training. Customers can choose whether or not we provide on-site support.

Q6: What is the equipment’s maintenance and spare parts support like? What is the after-sales service like?

A: We offer a limited warranty (generally 12 months) on key components (such as vacuum pumps, motors, and controllers).

We also provide a lifetime spare parts supply, allowing customers to order replacement parts at any time.

Remote technical support and video/illustrated guides assist with troubleshooting.

If a major malfunction occurs, we can arrange for a technician to visit the site to assist with repairs or provide a replacement solution.

Q7: I’m unsure which model/configuration to choose. Can you provide consulting/customization services?

A: Yes. Simply provide the size and weight of the glass you want to move/install, as well as the on-site operating environment (such as height, space constraints, and whether rotation is required). Our engineering team will recommend the most suitable model, suction cup layout, boom structure, and other customized solutions based on your needs.

Q8: What is the energy consumption, battery, and power supply method of this vacuum lifter? What is its battery life?

A:This device typically uses a DC motor drive and battery power supply (e.g., 2 x 12V/120Ah, depending on the model).

It has a built-in smart charger for automatic charging during off-peak hours.

Under typical loads and operating conditions, a single charge provides several hours of continuous operation. The specific battery life depends on frequency of use, load, and lift height.

For extended operations, an external power supply (e.g., AC power and a stable power outlet) is also available.

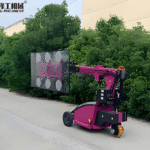

Why Choose YG Machinery?

YG Machinery is a trusted manufacturer and exporter with over 20 years of experience in the machinery industry. All our glass vacuum lifters for sale undergo strict quality inspection and testing before shipment. We offer:

- Factory-direct pricing;

- Customization options for suction arms and frame extensions;

- Fast delivery and full after-sales support across the United States.

With CE and ISO certifications, YG’s equipment is built to meet American safety and operational standards. We have successfully served customers in construction, manufacturing, solar energy, and glass production industries in over 30 states. In addition, we offer: glass handling robot, hydraulic scissor lift platform, etc. For a quote or technical consultation, please contact us anytime via 【WhatsApp/WeChat/Phone/Skype】+86 13837115193.